Amorphous titanium dioxide/nano iridium oxide/porous silicon anode and preparing method thereof

A titanium dioxide, nanoporous technology, applied in electrodes, gaseous chemical plating, coatings, etc., can solve the problems of reducing the catalytic performance of catalysts, requiring extremely high energy input, and high catalyst dosage, and maintaining high-efficiency characteristics and high electrochemical performance. The effect of stability, high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the nanoporous silicon substrate of the surface-loaded nano iridium oxide catalyst comprises the following steps:

[0042] A1. Preparation of nanoporous silicon substrate: Clean the silicon substrate material, form a nanoporous structure on the silicon substrate material by silver ion assisted chemical etching, and then treat it with concentrated nitric acid for 3-5 minutes, wash it, and dry it;

[0043] A2, the synthesis of iridium oxide catalyst precursor solution: K 2 IrCl 6 Dissolve in water with NaOH, stir and heat at 70°C for 40 minutes, then refrigerate at 4°C after cooling;

[0044] A3. Loading of iridium oxide catalyst: drip-coat the iridium oxide catalyst precursor solution prepared in step A2 on the surface of the nanoporous silicon substrate prepared in step A1, and evaporate the solvent to dryness at 80-150° C., and then anneal at low temperature, that is The nanoporous silicon substrate with nano iridium oxide catalyst supported...

Embodiment 1

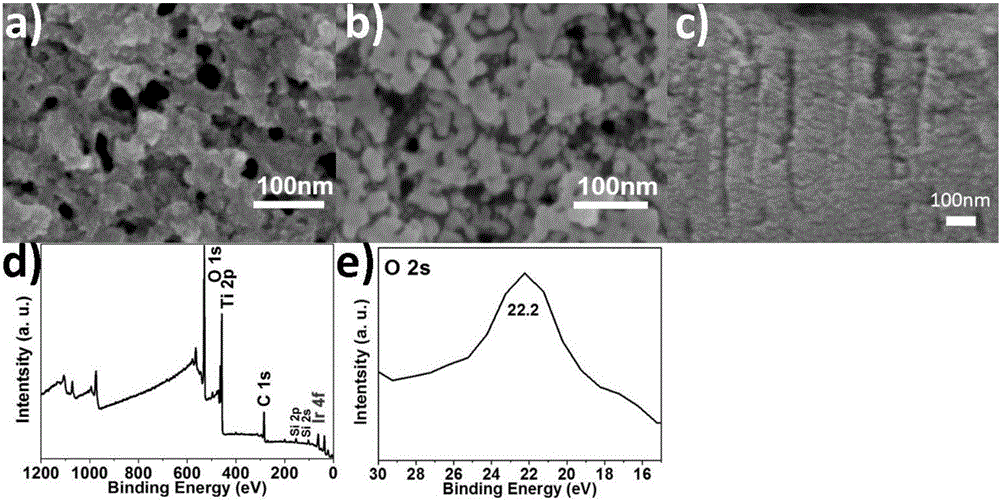

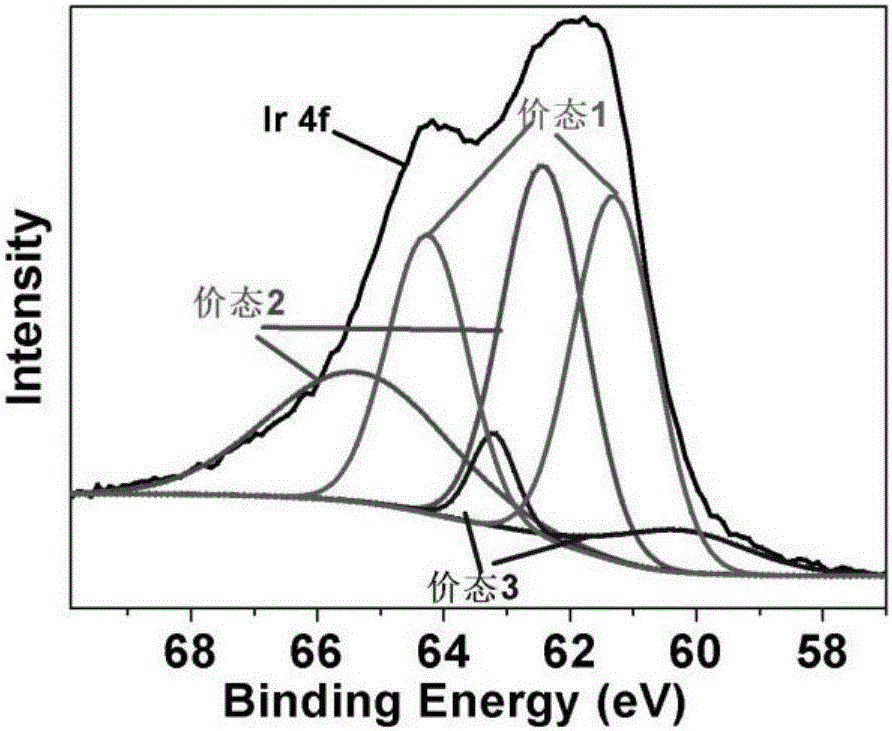

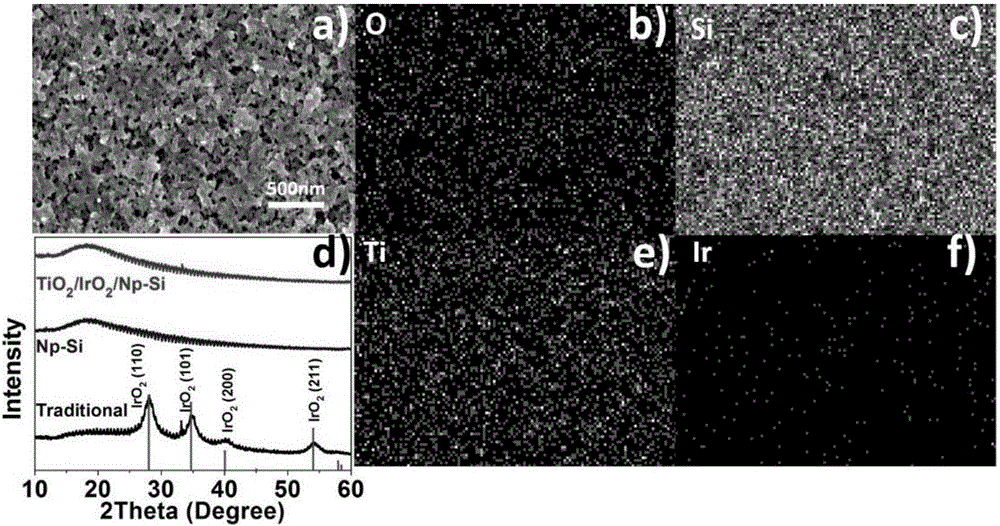

[0054] This embodiment provides a nano iridium oxide / porous silicon anode protected by amorphous titanium dioxide and a preparation method thereof, the anode includes a nanoporous silicon substrate with better hydrophilicity, an iridium oxide nano catalytic unit synthesized with an aqueous precursor, and Amorphous titanium dioxide layer for substrate and catalyst protection. Among them, the silver ion-assisted chemical etching method is used in the formation method of the nanoporous silicon structure, which can not only remove the silver ion but also achieve a certain degree of hydrophilicity on the surface during the nitric acid treatment process, thereby realizing the uniform distribution of the surface catalyst; A small amount of catalyst exists in an amorphous state, with at least three different valence states, and has high electrochemical catalytic oxygen production performance; the titanium dioxide protective layer exists in an amorphous state, and has certain leakage an...

Embodiment 2

[0072] In this example, the effects of different etching times on the performance of catalysts were compared. at 0.2g / cm 2 Under the condition of macroscopic catalytic amount, such as Image 6 As shown, under the condition of 6 minutes, the etching depth of 500nm, that is, the actual pore depth, is enough to disperse the catalyst, the catalytic performance changes little, and the high-efficiency catalytic performance of the catalyst can be maintained. Under the condition of 3 minutes, under the voltage of 1.5V, it is enough to see a large number of small bubbles being released rapidly; at 6 minutes, the release speed of the bubbles is still rapid, and it can be seen from the catalytic performance diagram that the effect is similar to that of 3 minutes; under the condition of 9 minutes, the release of bubbles becomes faster Slow, this is because the effect of the protective layer begins to deteriorate under the condition of 9min, and the performance of the catalyst begins to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com