A method for preparing quantum rod/polymer fiber membrane by electrospinning technology

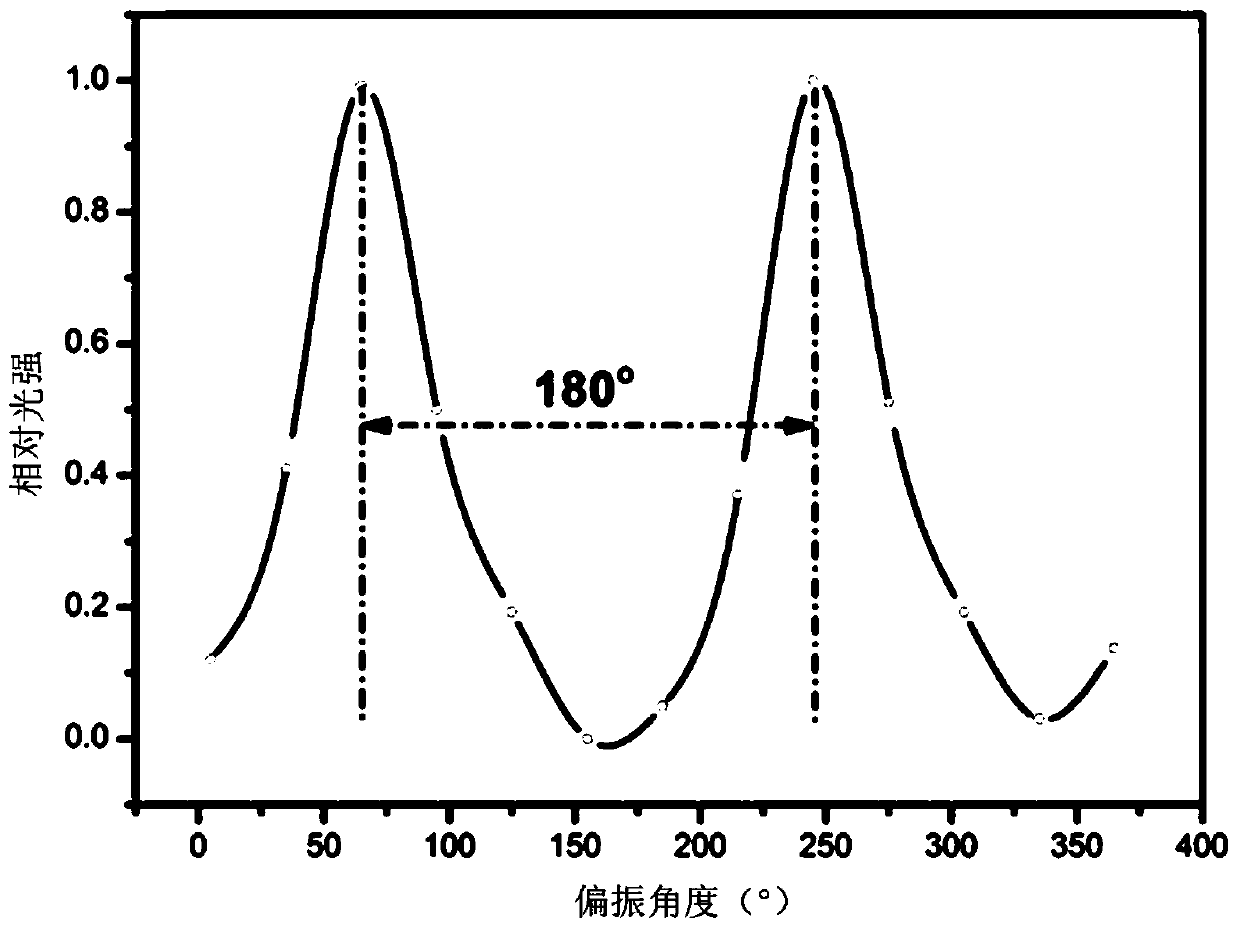

An electrospinning, quantum rod technology, applied in the field of optical materials, can solve the problems of poor controllability, complicated operation, limited degree of orientation and arrangement of quantum rod films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The specific embodiment part of the present invention provides a kind of preparation method of quantum rod / polymer fiber film, and described method comprises the following steps:

[0078] (1) Prepare quantum rod solution;

[0079] (2) Prepare a polymer solution, adding the quantum rod solution prepared in step (1) into the polymer solution to form a quantum rod volume concentration of 5% to 80% electrospinning precursor solution;

[0080] (3) Add the electrospinning precursor solution prepared in step (2) into the electrospinning device, adjust the voltage of the generator and the receiving distance, and perform electrospinning to prepare quantum rods / polymer fiber membranes.

Embodiment 1

[0083] This embodiment provides a method for configuring a CdSe / CdS quantum rod solution, the method comprising the following steps:

[0084] (a) Dissolve Se powder and S powder in tri-n-octylphosphine (TOP) respectively, heat and stir at 100°C until the solution becomes transparent, and prepare a Se-TOP solution with a concentration of 2.5mmol / mL and a concentration of 1mmol / mL S-TOP solution;

[0085] (b) Mix 26mg of CdO with 112mg of tetradecyl phosphoric acid (TDPA) and 1.5g of tri-n-octylphosphine oxide (TOPO), heat and stir at 350°C until CdO is completely dissolved and become transparent, then quickly add 0.75mL of TOP and step (a ) prepared 0.3mL of Se-TOP solution for reaction, after the reaction was completed, turn off the entire heating device to cool the solution to room temperature to obtain a nuclear solution of CdSe;

[0086] (c) The nuclear solution of CdSe was purified by centrifugation with chloroform and ethanol for 2 to 3 times, and dispersed into the TOP ...

Embodiment 2

[0089] This example provides a method for configuring a CdSe / CdS quantum rod solution, except for stirring at 50°C in step (a) to prepare a Se-TOP solution with a concentration of 2mmol / mL and a concentration of 0.5mmol / mL S-TOP solution; in step (b), the temperature of heating and stirring is 300°C; in step (d), the temperature of heating and stirring is 260°C, and 0.3mL of TOP and 0.3mL of S-TOP prepared in step (a) are quickly added in turn The TOP solution and 0.2mL of the CdSe-TOP solution prepared in step (c) were reacted at 300°C for 15 minutes, and the dosage and preparation method of other materials were the same as those in Example 1 to finally obtain a CdSe / CdS quantum rod solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com