Construction method utilizing blown sand cofferdam as cast-in-situ box beam support foundation

A technology for foundation construction and cofferdam, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult construction, difficult dismantling, complicated processes, etc., and achieve high utilization efficiency, high practical value, and method steps. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

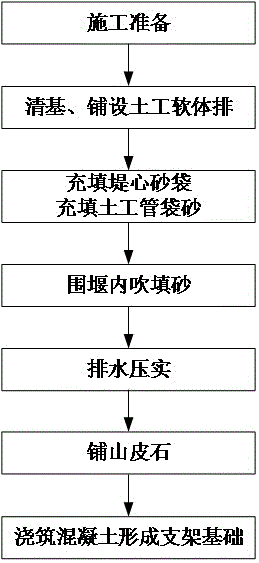

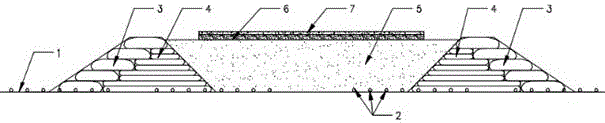

[0028] see Figure 1~2 , in an embodiment of the present invention, a sand blowing cofferdam is used as a construction method for the cast-in-place box girder support foundation, comprising the following steps:

[0029] Step 1. Surveyors measure and locate the plane position and elevation of the sandbag cofferdam;

[0030] Step 2. Before the laying of the soft row 1, the GPS navigation and positioning system is used to measure and locate it. If there are sharp objects, take measures to deal with them immediately to ensure that the row is not damaged. And use the mud pump set equipped on the sand blowing ship to flush and fill the sand rib 2 in time to prevent the soft body row 1 from being washed away by water flow and waves, and tighten the filling port when it is full; the filling rate of the sand rib 2 is 80%; The overlapping length of two adjacent soft-body rows 1 shall not be less than 2000mm for underwater construction and not less than 1000mm for underwater constructio...

Embodiment 2

[0041] see Figure 1~2 , in an embodiment of the present invention, a sand blowing cofferdam is used as a construction method for the cast-in-place box girder support foundation, comprising the following steps:

[0042] Step 1. Surveyors measure and locate the plane position and elevation of the sandbag cofferdam;

[0043] Step 2. Before the laying of the soft row 1, the GPS navigation and positioning system is used to measure and locate it. If there are sharp objects, take measures to deal with them immediately to ensure that the row is not damaged. And use the mud pump set equipped on the sand blowing ship to flush and fill the sand rib 2 in time to prevent the soft body row 1 from being washed away by water flow and waves, and tighten the filling port when it is full; the filling rate of the sand rib 2 should be 85%; The overlapping length of two adjacent pieces of software row 1 shall not be less than 2000mm for underwater construction and not less than 1000mm for underwa...

Embodiment 3

[0053] see Figure 1~2 , in an embodiment of the present invention, a sand blowing cofferdam is used as a construction method for the cast-in-place box girder support foundation, comprising the following steps:

[0054] Step 1. Surveyors measure and locate the plane position and elevation of the sandbag cofferdam;

[0055] Step 2. Before the laying of the soft row 1, the GPS navigation and positioning system is used to measure and locate it. If there are sharp objects, take measures to deal with them immediately to ensure that the row is not damaged. And use the mud pump set equipped on the sand blowing ship to fill the sand rib 2 in time to prevent the soft body row 1 from being washed away by water flow and waves, and tighten the filling port when it is full; the filling rate of the sand rib 2 should be 90%; The overlapping length of two adjacent pieces of software row 1 shall not be less than 2000mm for underwater construction and not less than 1000mm for underwater constr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com