Supercritical Once-through Boiler Ignition Steam Blowpipe Energy Saving and Emission Reduction Commissioning Method

A once-through boiler, energy-saving and emission-reduction technology, applied in combustion methods, lighting and heating equipment, solid residue removal, etc., can solve the problems of waste of non-renewable resources, pollutant discharge, hidden safety hazards of temporary systems, and large impact of temporary systems , to achieve the effect of reducing the waste of non-renewable resources and pollutant emissions, maximizing economic and environmental benefits, and reducing the number of blowpipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the debugging method for energy saving and emission reduction of supercritical once-through boiler ignition steam blowing pipe of the present invention comprises the following steps:

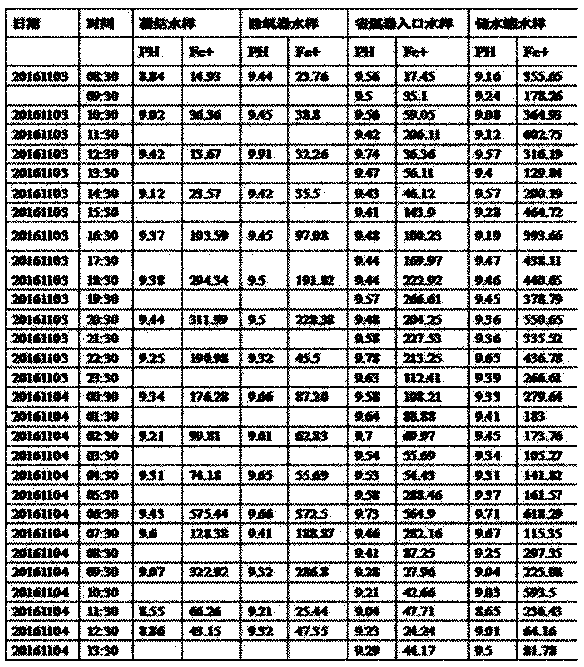

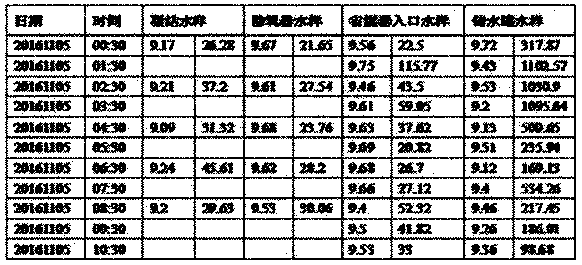

[0021] Process 1, large amount of water flushing in the cold state: the whole furnace is drained three times, the economizer and the water wall system are filled with water and then completely drained, and then the water is refilled and then drained, and finally the water is filled and drained for flushing ;

[0022] Process 2, cold cycle flushing: when the Fe+ at the outlet of the separator is started to be greater than 1000ug / L, perform cold drain flushing, and drain to the circulating water backwater; Put into the pre-finishing pre-filter, rinse and drain and start recycling to the circulating water system; when the water quality Fe+ at the separator outlet is less than 500ug / L, put it into the high-speed mixed bed, and start closed cold flushing; when the water qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com