Rapid variable load optimizing control method for oxygen and nitrogen rectification outer compression air separation plant

A technology for optimized control and air separation equipment, applied in lighting and heating equipment, liquefaction, cold treatment separation, etc., can solve problems such as energy consumption and economic loss, high oxygen emission, and production load that cannot be adjusted in time to reduce process variables Fluctuation range, effect of reducing oxygen emission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

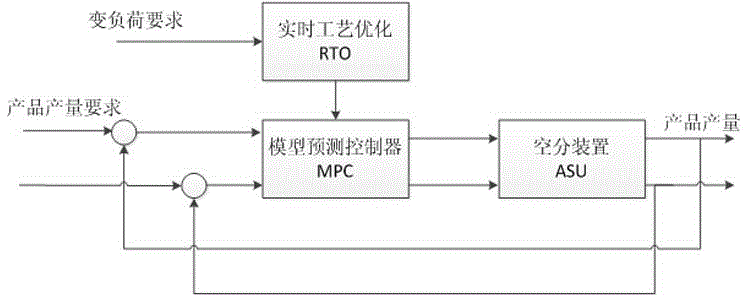

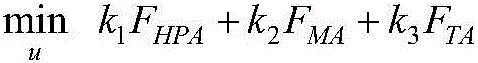

[0035] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment: figure 1As shown, a fast variable load optimization control method for oxygen and nitrogen rectification external compression air separation equipment, the fast variable load optimal control method is: a two-layer combination of large-scale process optimization and nonlinear predictive control The architecture includes two modules of process optimization calculation (RTO) and model predictive control (MPC). According to the variable load requirements of the device, the RTO module calculates the optimal steady-state value of the process variable related to the load change through the optimization calculation of the air separation low-temperature cryogenic process, and sends it to the multivariable predictive control MPC; the MPC module is in the Under the premise of not violating equipment constraints and ensuring product quality, gradually push the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com