Fiber Fabry-Perot sonic probe device and manufacturing method thereof

A technology of percosonic wave and optical fiber method, which is applied in the field of optical fiber method percosonic wave probe device and metal-doped graphene film, which can solve the problems of low detection sensitivity of external pressure or acoustic wave signal, low contrast of interference fringes, etc., and achieve improved reception rate, Create simple, contrast-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

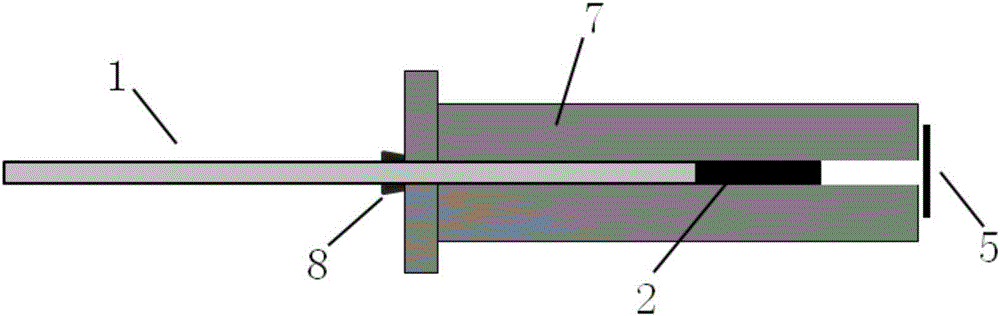

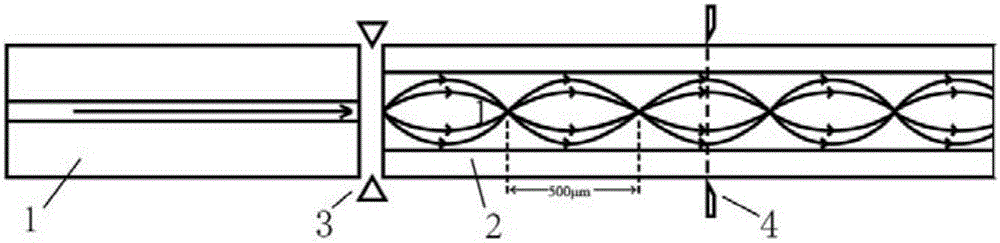

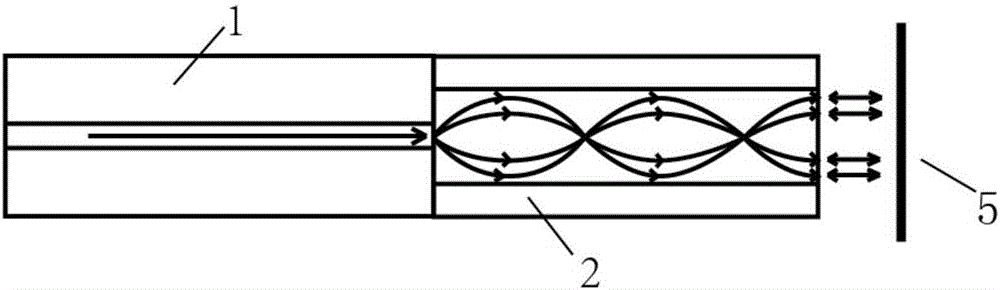

[0027] figure 1 It is the device diagram of our acoustic wave probe. The single-mode fiber is welded with a section of graded multimode fiber. The end face of the graded multimode fiber and the graphene film form two light reflection surfaces, forming a F-Per interference cavity. The quartz glass sleeve plays the role of fixing and alignment. The role of straight fiber. Among them, the core diameter of the single-mode fiber is 9 microns, and the cladding diameter is 125 microns. The core diameter of the graded multimode fiber is 62.5 microns, the cladding diameter is 125 microns, the self-focusing period of the graded multimode fiber is 500 microns, and the length of the graded multimode fiber is 1250 microns. figure 2 It is a diagram of the manufacturing method of the optical fiber end face of the device. First, the end faces of a section of sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Cladding diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com