Nitrogen-doped graphene modified graphite puree and preparation method thereof

A graphene modification, graphene technology, applied in cable/conductor manufacturing, carbon-silicon compound conductors, electrical components, etc., can solve the problems of low electrical conductivity of brush thickness and further improvement of electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0018] Preparation of nitrogen-doped graphene: 155g of urea (analytical pure) was added to 100mL of graphene oxide solution, after fully stirring and mixing; air-dried at 40°C for 10h to obtain a mixed powder; then the mixed powder was calcined to obtain the Nitrogen doped graphene. Wherein, the steps of calcination used are: starting from 20°C to 800°C and maintaining at 800°C for 1 hour, wherein the heating rate is 5°C / min; then cooling down to 30°C at a cooling rate of 10°C / min; wherein, the The calcination atmosphere is N 2 , N 2 The flow rate is 0.001m 3 / h.

preparation example 2

[0020] Preparation of nitrogen-doped graphene: Add 200g of urea (analytical pure) to 100mL of graphene oxide solution, stir and mix thoroughly; blow dry at 60°C for 6h to obtain mixed powder; then calcinate the mixed powder to obtain the Nitrogen doped graphene. Wherein, the steps of calcination used are: starting from 20°C to 800°C and maintaining at 800°C for 1 hour, wherein the heating rate is 5°C / min; then cooling down to 30°C at a cooling rate of 10°C / min; wherein, the The calcination atmosphere is N 2 , N 2 The flow rate is 0.001m 3 / h.

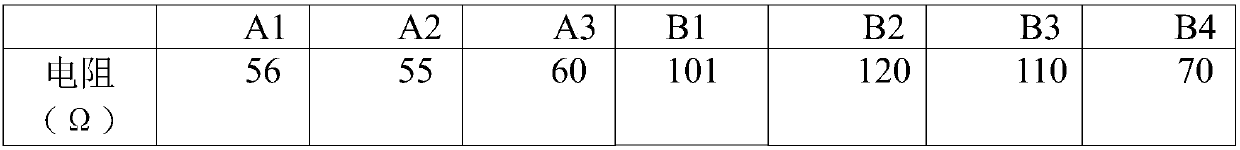

Embodiment 1

[0022] Nitrogen-doped graphene, conductive graphite, polypropylene resin (with a weight average molecular weight of 10,000), glass powder, zinc powder, terpineol, ethyl cellulose and polyvinylpyrrolidone in a weight ratio of 21:100: 25:1:1:30:1:1 Stirring for 2 hours at a rotational speed of 2000rpm to obtain nitrogen-doped graphene modified graphite puree A1;

[0023] Wherein, the added nitrogen-doped graphene is prepared from Preparation Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com