Selective removal of boron doped carbon hard mask layer

A film and plasma technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problem of difficult removal of the hard mask layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

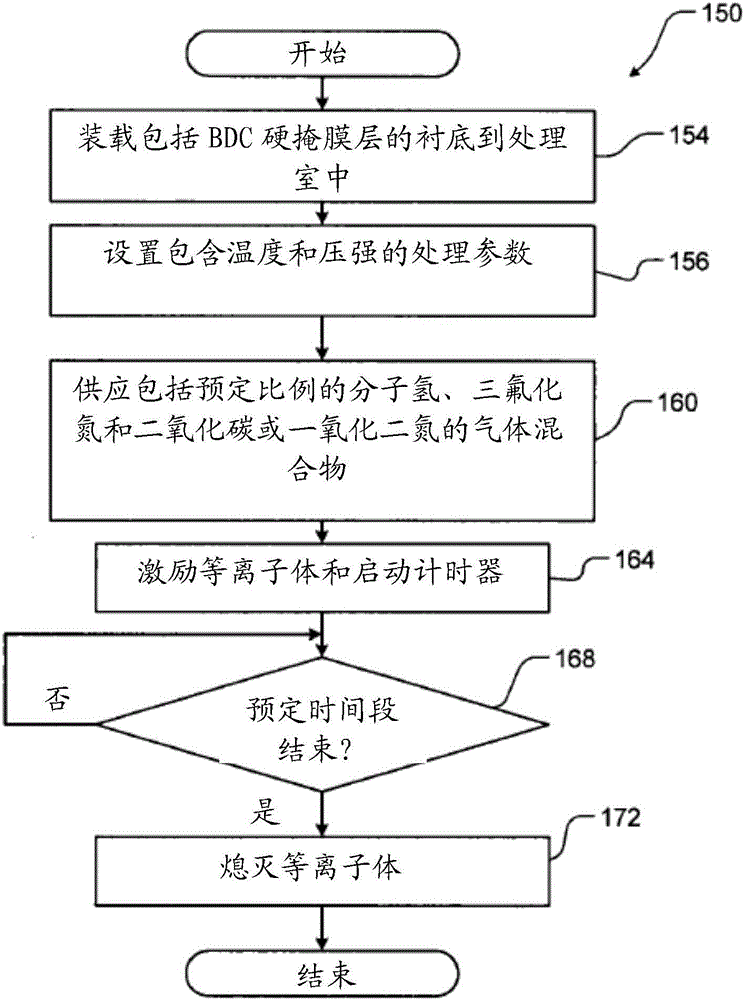

[0045] Substrate processing systems and methods according to the present disclosure are used to strip a boron doped carbon (BDC) hard mask layer from a substrate during substrate processing. The plasma is generated using a gas mixture that includes molecular hydrogen (H 2 ), nitrogen trifluoride (NF 3 ) and selected from carbon dioxide (CO 2 ) and nitrous oxide (N 2 The gases in the group consisting of O). The plasma treatment strips the BDC hard mask layer with high selectivity to the underlying film layer.

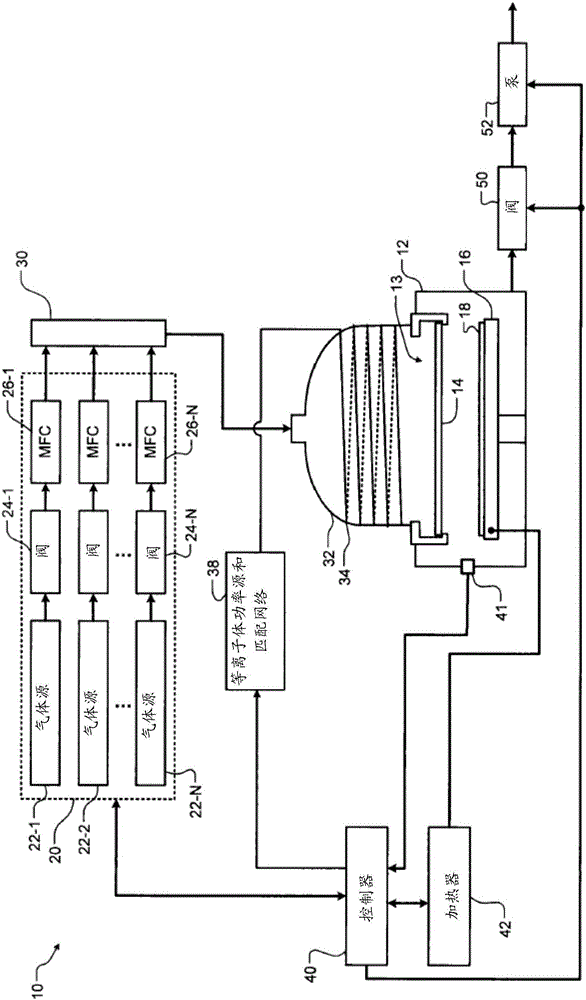

[0046] now refer to figure 1, an example of a substrate processing system 10 is shown. Although a specific processing chamber is shown, other types of chambers may also be used. The substrate processing system 10 includes a lower chamber 12 and a gas distribution device 13 such as a face plate or a showerhead 14 including spaced through holes. In some examples, substrate processing system 10 provides a remote or downstream plasma. A substrate support 16 may be ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com