MPS diode and manufacturing method therefor

A technology of diode and ion implantation area, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems of increasing device leakage risk, device surface damage, and implantation dose should not be too small, so as to ensure ohmic contact quality, improved performance, and reduced leakage current effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

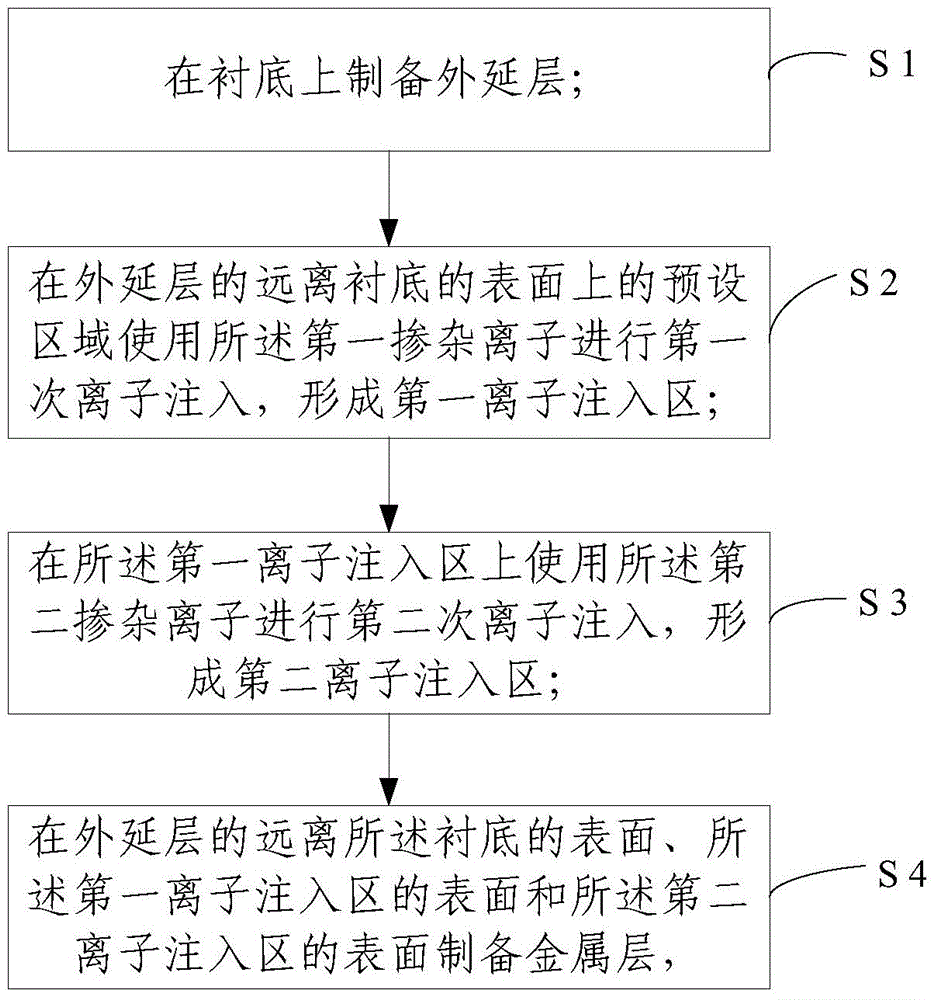

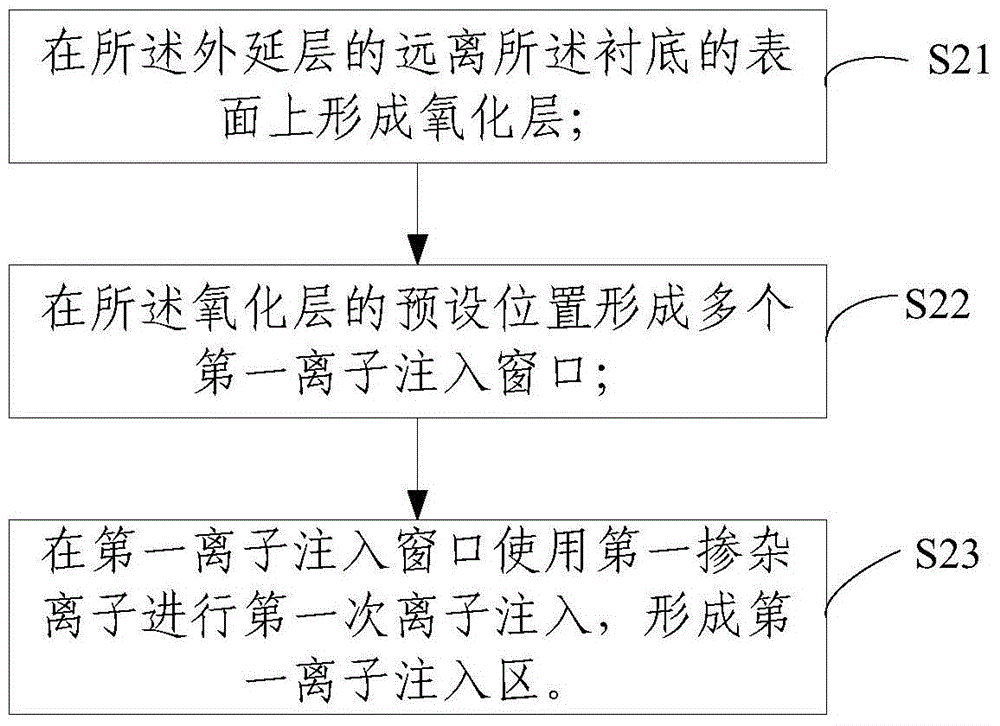

[0038] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0039] The MPS diode is a device structure that can be designed to exhibit the low turn-on voltage of a Schottky diode in the forward direction and the low reverse leakage current of a P-i-N diode in the reverse direction. MPS diodes may include Schottky contacts with one or more buried p-n junctions (or P-i-N regions) in the area of the contacts. The forward conduction voltage is controlled by the Schottky section before the p-n junction conducts at a higher voltage. The reverse mode of operation is controlled through appropriately spaced p-n junctions. Furthermore, in some embodiments, the same process used to form the p-n junction buried within the region of the Schottky contact can also be used to form the edge termination structure to provide an edge termination for the MPS diode.

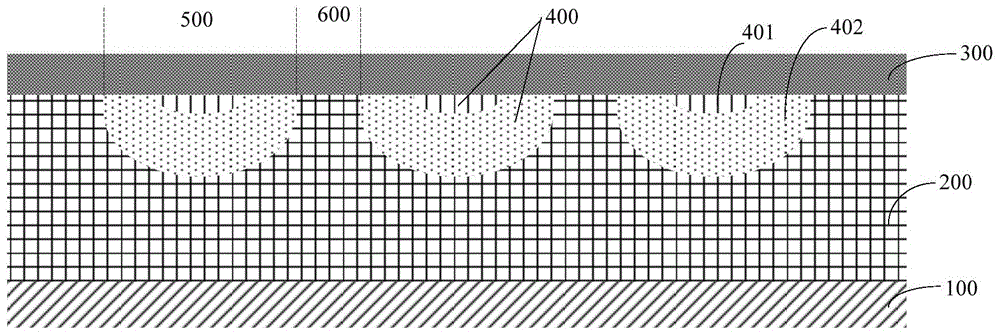

[0040] figure 1 A schematic cross-sectional view of the MPS di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com