Water-blocking type radio frequency coaxial cable and manufacturing process thereof

A technology of radio frequency coaxial cable and manufacturing process, which is applied in the direction of circuits, electrical components, waveguide devices, etc., can solve problems such as abnormal operation of equipment, weakened signal transmission performance, scrapped and replaced cables, etc., and achieve good water blocking effect and speed Fast, high-throughput results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

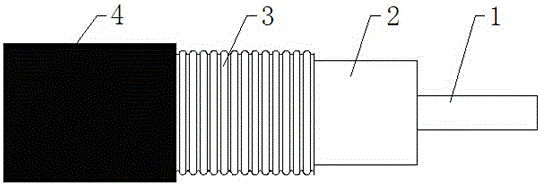

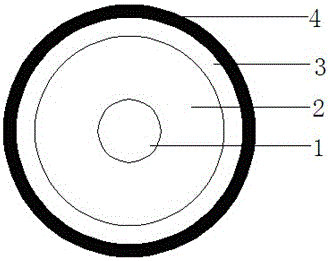

[0018] Such as figure 1 and figure 2 As shown, a water-blocking type radio frequency coaxial cable, the cable structure is arranged in sequence from the inside to the outside: the cable inner conductor 1, the insulation layer 2 is arranged outside the cable inner conductor 1, the outer conductor 3 is arranged outside the insulation layer 2, the outer conductor 3. Protective layer 4 is set outside. Wherein, the outer conductor 3 is composed of aluminum rods through continuous extrusion, stretching, cooling, and embossing; After the machine, medium-frequency induction is used to heat and extrude in sections, and high-strength carbon steel material screws and barrels are used for homogeneous extrusion, and then split and joined to form aluminum tubes with uniform thickness, which are then coated on the surface of the core wire through stretch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com