Microwave ionization-based pollution removal system and removal method for dielectric film surface

A technology of dielectric film layer and surface pollution, which is applied to the cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc. Fingerprint pollution, the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

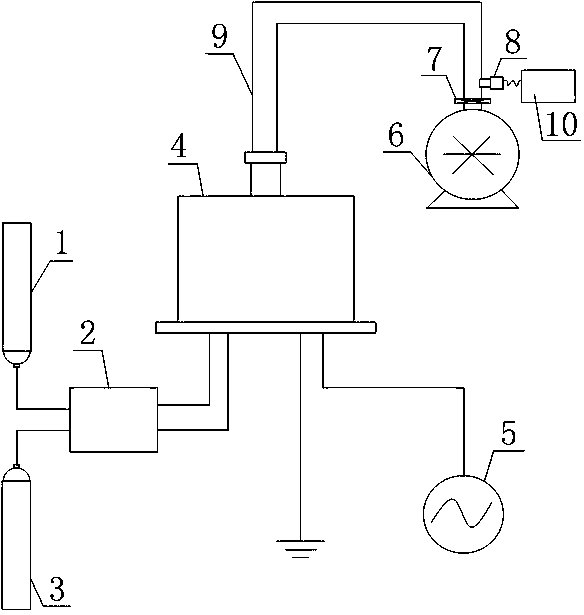

[0025] like figure 1 As shown, a microwave ionization-based dielectric film surface pollution removal system and its removal method include a sample chamber 4, and the sample chamber 4 is externally provided with a microwave source 5, a vacuum mechanism, a gas flow control system 2, an oxygen source 1 and helium Gas source, the oxygen source 1 is contained in an oxygen cylinder during actual use, and the helium source is contained in a helium cylinder. The vacuum mechanism includes a vacuum pump 6, a flap valve 7, a vacuum gauge 10 and a vacuum gauge 8. The vacuum pump 6 is connected to bellows 9, and the bellows 9 communicates with the inside of the sample chamber 4, the vacuum pump 6 extracts air from the sample chamber 4 through the bellows 9, and the gate valve 7 is arranged between the bellows 9 and the vacuum pump 6 and is simultaneously connected with the bellows 9 and The vacuum pump 6 is connected, and the cross-section of the flapper valve 7 is large, which can compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com