Intermediate billet inclined jet flow cooling and shape control method

A technology of plate shape control and jet flow, applied in the field of steel rolling process, can solve the problem of limited cooling capacity of aerosol mist, and achieve the effect of large adjustment range, improved heat exchange efficiency and flexible layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

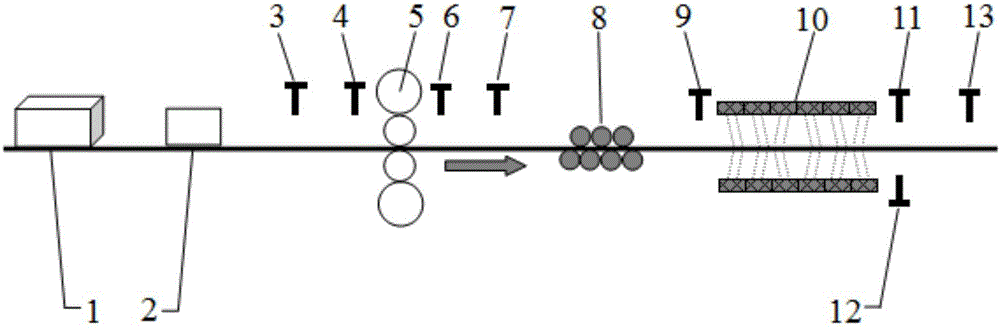

[0020] The size of the Q550-ZB-1 billet in this embodiment is 220mm*2150mm*2510mm, the size of the intermediate billet is 72.11mm*2666mm*6500mm, the size of the rolled steel plate is 40.25mm*2617mm*11393mm, and the method of cooling the intermediate billet with an inclined jet stream and controlling the shape of the plate is specific for:

[0021](1) The billet is discharged from the heating furnace 1, and the tapping temperature is 1199°C. After being descaled by the descaling box 2, it enters the rolling mill 5 for rough rolling. Adjust the line speed of the upper work roll to 105%-110% of the line speed of the lower work roll, and adjust the line speed of the upper work roll to 90%-95% of the line speed of the lower work roll to make the intermediate blank The shape is straight. The PDI (Primary Data Input) information of the intermediate billet (including the ID number of the intermediate billet, the steel type of the billet, the thickness of the intermediate billet, the ...

Embodiment 2

[0027] The size of the X70MO billet in this embodiment is 320mm*2100mm*3585mm, the size of the intermediate billet is 125mm*2160mm*9400mm, and the size of the rolled steel plate is 41.69mm*2152mm*28090mm.

[0028] (1) The billet is discharged from the heating furnace 1, and the tapping temperature is 1186°C. After being descaled by the descaling box 2, it enters the rolling mill 5 for rough rolling. Adjust the line speed of the upper work roll to 105%-110% of the line speed of the lower work roll, and adjust the line speed of the upper work roll to 90%-95% of the line speed of the lower work roll to make the intermediate blank The shape is straight. The PDI (Primary Data Input) information of the intermediate billet (including the ID number of the intermediate billet, the steel type of the billet, the thickness of the intermediate billet, the width of the intermediate billet, the length of the intermediate billet, the cooling speed, the final cooling temperature, etc.) 5 The ...

Embodiment 3

[0034] The size of the X70MO billet in this embodiment is 320mm*2100mm*3586mm, the size of the intermediate billet is 125mm*2160mm*9402mm, the size of the rolled steel plate is 41.72mm*2152mm*27869mm, the method of cooling the intermediate billet with inclined jet flow and controlling the plate shape is as follows:

[0035] (1) The billet is discharged from the heating furnace 1, and the tapping temperature is 1145°C. After being descaled by the descaling box 2, it enters the rolling mill 5 for rough rolling. Adjust the line speed of the upper work roll to 105%-110% of the line speed of the lower work roll, and adjust the line speed of the upper work roll to 90%-95% of the line speed of the lower work roll to make the intermediate blank The shape is straight. The PDI (Primary Data Input) information of the intermediate billet (including the ID number of the intermediate billet, the steel type of the billet, the thickness of the intermediate billet, the width of the intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com