Storage and transfer robot used for modern logistics industry

A technology for handling robots and robots, which is applied to pedestrian/occupant safety arrangements, instruments, motor vehicles, etc., can solve the problems of inability to transmit control terminals, large size, low reliability, etc., and achieves a simple structure and structure of the device and improves sorting efficiency. , the effect of reducing logistics costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

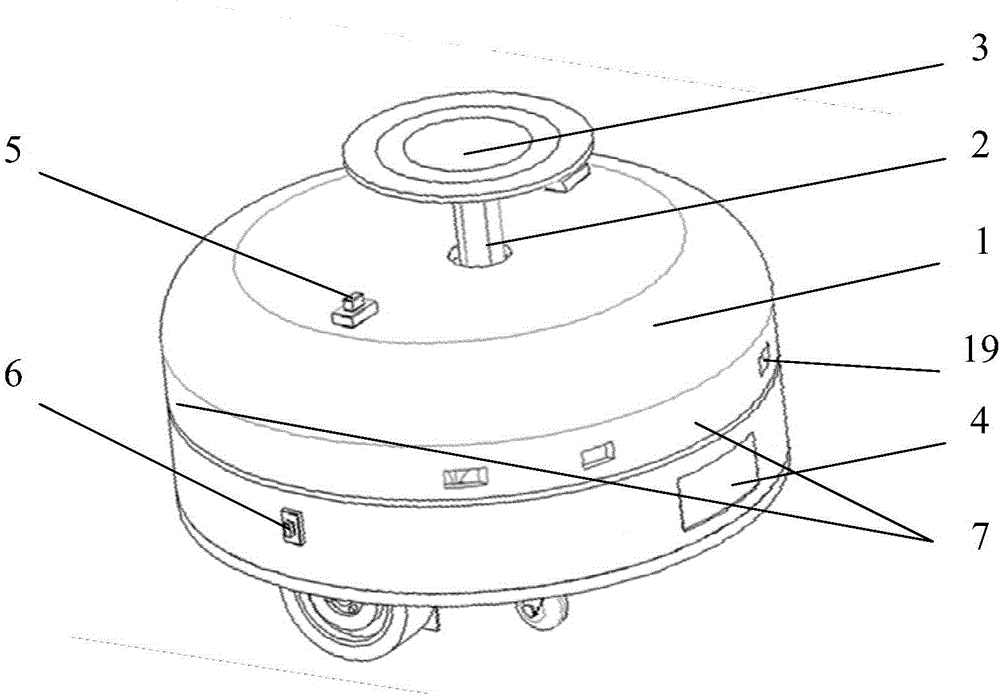

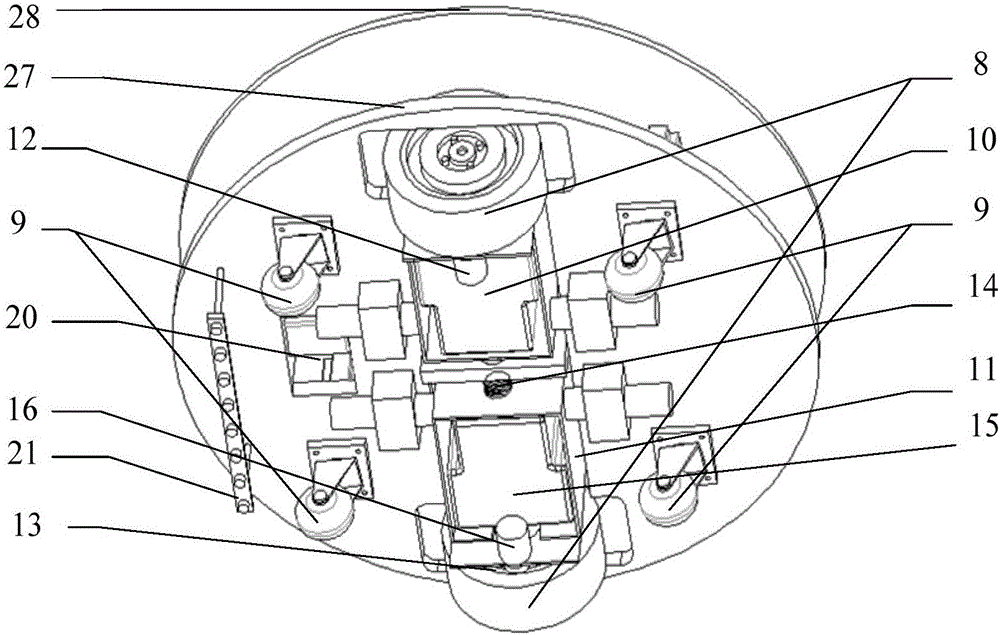

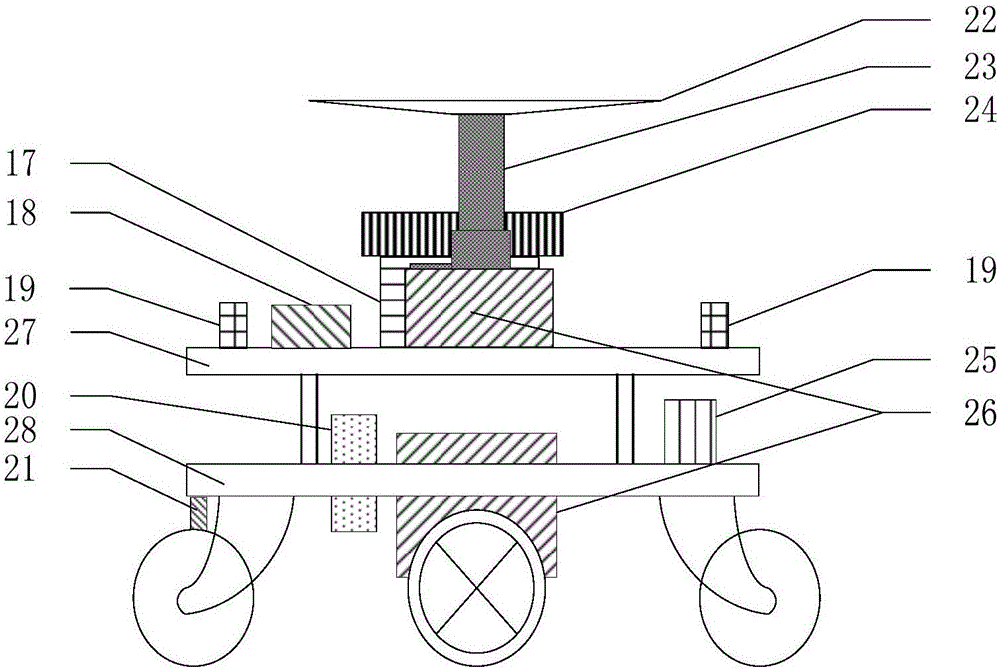

[0057] combine figure 1 and Figure 11 ,, In this embodiment, it includes the robot body, the sensors mounted on the robot body and the control terminal 36 . The storage and handling robot operates in an indoor working area such as an e-commerce distribution center, so that the storage and handling robot body can travel from the departure area 32 along a specific landmark 40 to the bottom of the shelf, and transport the designated shelf 44 to the sorting area 34 and then Put back shelf 44, finally robot gets back to starting area 32 and waits for instruction.

[0058] Such as figure 1 As shown, the warehouse handling robot includes a chassis mechanism of the handling robot body, a housing 1, a lifting mechanism 2, a charging interface 3, a main switch 6, an emergency stop button 5, and sensors carried by the robot. The chassis mechanism of the handling robot body is the skeleton supporting the overall structure of the robot. The shell 1 is similar to the skin and protects t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com