Method for recycling sulphur from sulphur-containing residue

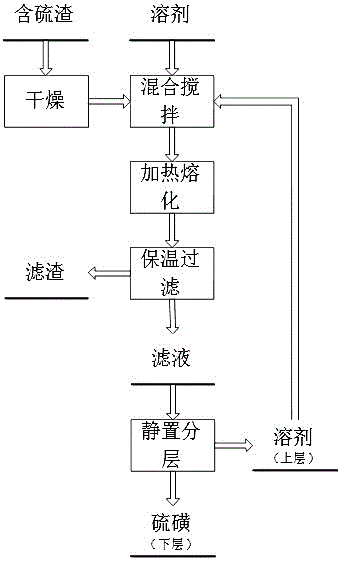

A sulfur and filter residue technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of high requirements for thermal filtration equipment, easy to block pipelines, etc., and achieve the effect of small investment, simple equipment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 200g of sulfur-containing residue and 1000ml of kerosene to the triangular beaker in turn, turn on the magnetic stirring, turn on 800r / min, heat to 135°C for 10 minutes to fully melt the sulfur, keep the temperature of the mixture, and quickly filter it. When there is no drop for a long time, use a small amount of 135℃ kerosene to rinse the filter residue in the funnel. After the filtration is completed, take out the filter residue and dry it to recover the kerosene. The slag desulfurization rate is 98.5%, the desulfurization slag rate is 27.86%, the sulfur content in the desulfurization slag is 3.85%, and the enrichment of valuable metals in the slag exceeds 3 times.

Embodiment 2

[0021] Add 200 grams of sulfur-containing slag and 800ml of kerosene to the triangular beaker in turn, turn on the magnetic stirrer, turn on 600r / min, heat to 140°C and keep it warm for 30 minutes to fully melt the sulfur, keep the temperature of the mixture and quickly filter it. When there is no drop for a long time, use a small amount of 140℃ kerosene to rinse the filter residue in the funnel. After the filtration is completed, take out the filter residue and dry it to recover the kerosene. The slag desulfurization rate is 98.4%, the desulfurization slag rate is 27.98%, the sulfur content in the desulfurization slag is 4.14%, and the enrichment of valuable metals in the slag exceeds 3 times.

Embodiment 3

[0023] Add 200 grams of sulfur-containing slag and 500ml of kerosene to the triangular beaker in turn, turn on the magnetic stirrer, turn on 400r / min, heat to 140°C and keep it warm for 60 minutes to fully melt the sulfur, keep the temperature of the mixture and quickly filter it. When there is no drop for a long time, use a small amount of 140℃ kerosene to rinse the filter residue in the funnel. After the filtration is completed, take out the filter residue and dry it to recover the kerosene. The slag desulfurization rate is 98.2%, the desulfurization slag rate is 28.17%, the sulfur content in the desulfurization slag is 4.57%, and the enrichment of valuable metals in the slag is more than 3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com