Energy plant remediation method for heavy metal contaminated soil and modifying agent for energy plant remediation method

A technology of energy plants and restoration methods, which is applied in the restoration of polluted soil, soil conditioning materials, chemical instruments and methods, etc., can solve the problems of incomplete treatment of heavy metals, easy reactivation of heavy metals, and inhibition of plant growth, etc. Biomass and enrichment effects, effects that contribute to healthy growth, significant economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention has no special limitation on the preparation method of the improvement agent described in the above technical solution, and the technical solution prepared by a composition well known to those skilled in the art can be adopted, specifically: adjusting the bio-organic fertilizer, peat soil and pH The agent is mixed to obtain the modifier used in the heavy metal polluted soil energy phytoremediation method. In the present invention, the mixture is preferably stored in bags, preferably 50 kg per bag, so as to facilitate the metering during administration.

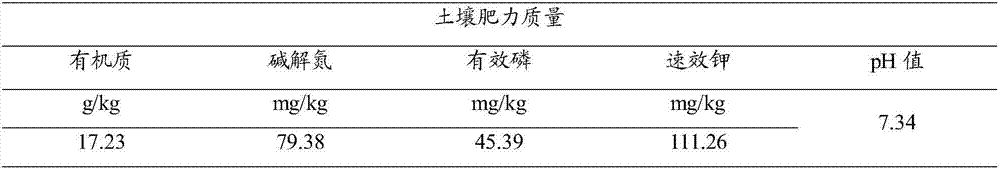

[0035] In the present invention, the improvement agent described in the above technical solution is applied to the heavy metal polluted soil. In the present invention, the application amount of the improver is preferably based on the amount of organic matter in the soil that is not less than 15g / kg, more preferably 16-20g / kg; Before, the present invention preferably measures the organic matter conte...

Embodiment 1

[0054] Preparation of improver: 86% of plant straw, 10% of animal manure and 4% of biochar are prepared, and fermented to obtain bio-organic fertilizer; % mixed to obtain a soil conditioner.

[0055] The organic matter content in the soil of the test field was measured, and the soil conditioner was applied in the test fields of plots A, B, C and D according to the amount of 50Kg applied per mu.

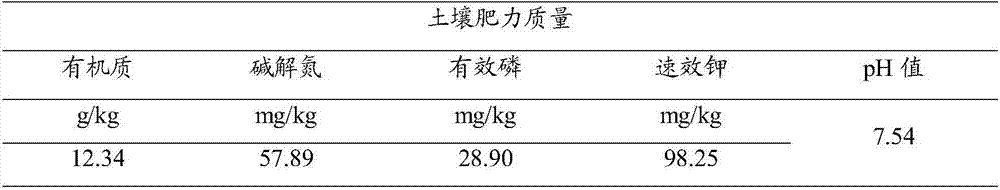

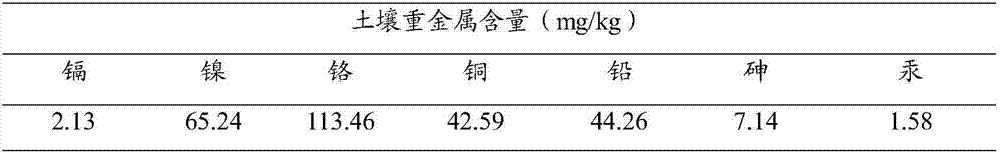

[0056] Take 3 samples of soil according to the principle of random sampling, and the sampling depth of the sample soil shall not exceed 25cm. The sample soil was ventilated and dried in a cool place, and the soil organic matter content, pH value and heavy metal content parameters were measured after removing impurities. The results are shown in Table 3.

[0057] Table 3 Soil fertility quality table after fertilization

[0058]

[0059] After the test field after the application of the improver in plot A was dried for one day, the plot A was divided into a row of 300cm wide strips...

Embodiment 2

[0061] After the test field after the application of the improver in the B plot was dried for one day, the B plot was divided into 200cm×300cm block land, and the castor was planted in block form.

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com