A kind of nise three-dimensional porous nano-sheet material and preparation method thereof for supercapacitor

A supercapacitor, three-dimensional porous technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, binary selenium/tellurium compounds, etc. The effect of migration, increasing specific surface area, and increasing specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

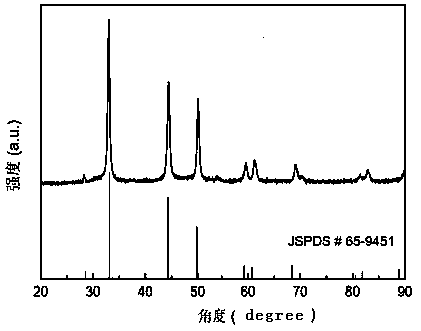

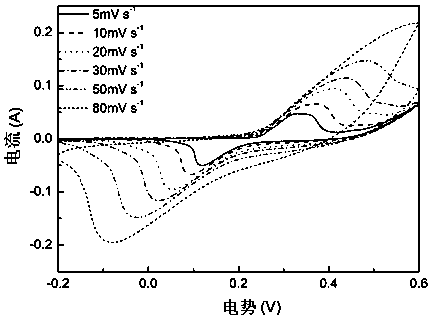

Embodiment 1

[0033] (1) Cut the nickel foam into a size of 4cm×2cm, and put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0034] (2) Weigh 1mmol of nickel chloride hexahydrate and 1mmol of sodium selenite and dissolve them in 36mL of deionized water, then add 4mL of hydrazine hydrate and stir for 30min to obtain a precursor solution.

[0035](3) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated in step (1) in it, put the reaction kettle into a drying oven, and react at 140°C for 24h, then Cool the reactor to room temperature, collect the nickel foam, rinse with ethanol and deionized water, and dry, and the final sample obtained is a NiSe three-dimensional porous nanosheet material.

Embodiment 2

[0037] (1) Cut the nickel foam into a size of 4cm×2cm, and put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0038] (2) Weigh 1mmol of nickel chloride hexahydrate and 1mmol of sodium selenite and dissolve them in 36mL of deionized water, then add 6mL of hydrazine hydrate and stir for 30min to obtain a precursor solution.

[0039] (3) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated in step (1) in it, put the reaction kettle into a drying oven, and react at 140°C for 12h, then Cool the reactor to room temperature, collect the nickel foam, rinse with ethanol and deionized water, and dry, and the final sample obtained is a NiSe three-dimensional porous nanosheet material.

Embodiment 3

[0041] (1) Cut the nickel foam into a size of 4cm×2cm, and put it in a 3 mol L -1 In the hydrochloric acid solution, ultrasonically react for 30 minutes to remove the NiO layer on the surface, and wash the treated nickel foam with deionized water and ethanol until neutral.

[0042] (2) Weigh 1mmol of nickel chloride hexahydrate and 1mmol of sodium selenite as raw materials and dissolve them in 36mL of deionized water, then add 8mL of hydrazine hydrate and stir for 30min to obtain a precursor solution.

[0043] (3) Pour the above mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, place the nickel foam treated in step (1) in it, put the reaction kettle into a drying oven, and react at 140°C for 8 hours, then Cool the reactor to room temperature, collect the nickel foam, rinse with ethanol and deionized water, and dry, and the final sample obtained is a NiSe three-dimensional porous nanosheet material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com