Separation method for methanol-to-propylene (MTP) reaction product

A reaction product, methanol conversion technology, applied in chemical instruments and methods, distillation purification/separation, hydrocarbon purification/separation, etc., can solve the problems of propylene recovery rate, high energy consumption, complicated separation process, etc., and achieve significant energy saving , The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

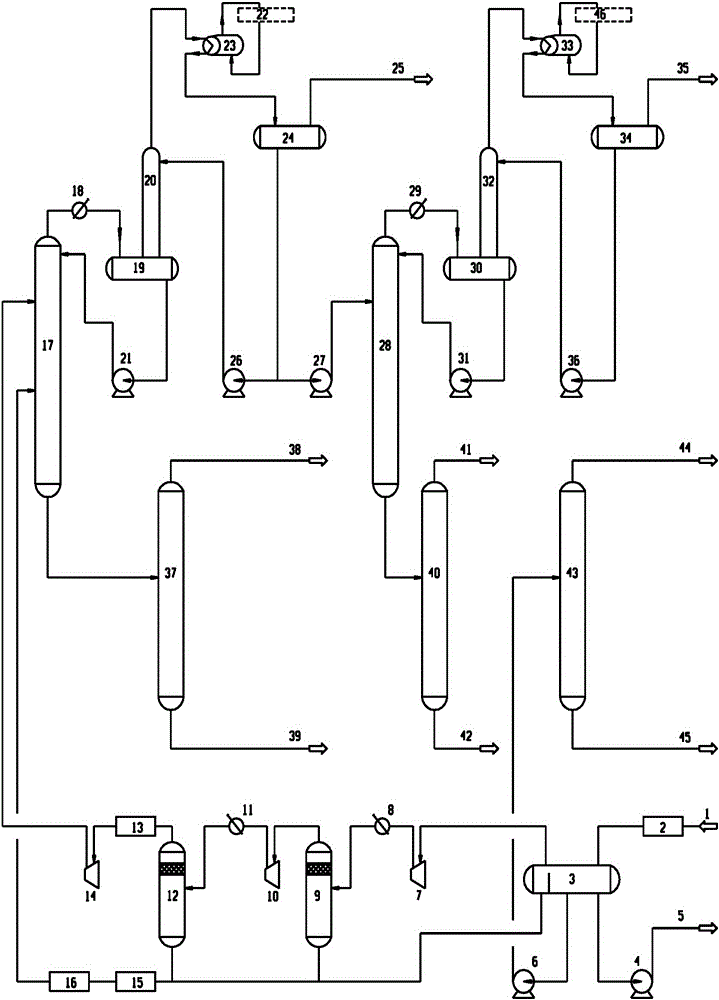

[0029] Such as figure 1 As shown, the MTP reaction product 1 enters the reaction product separator 3 after being pretreated by the pretreatment system 2, and is separated into a gas phase product, a liquid phase product and process water in the reaction product separator 3, and the gas phase product is sent to the compression unit for compression. The first stage 7 of the machine is compressed to 0.15-0.25MPa (g), the temperature is 60-70°C, and it enters the first-stage outlet cooler 8 to cool to 38-42°C, and the gas-liquid separation is carried out in the primary liquid separation tank 9 to obtain the primary gas phase product and the primary condensate. Liquid, the primary gas phase product is compressed to 0.5-0.80MPa(g) by the second stage 10 of the compressor, the temperature is 80-95°C, it enters the second-stage outlet cooler 11 and is cooled to 38-42°C, and passes through the secondary liquid separation tank 12 gas liquid separation to obtain the secondary gas phase p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com