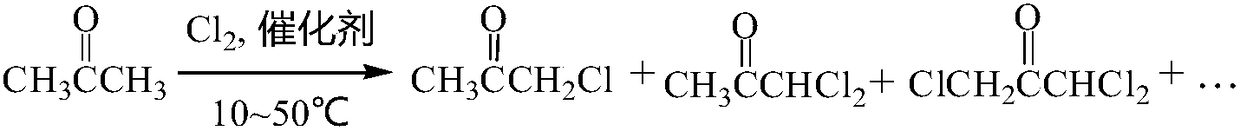

A preparation method for improving the synthesis yield of 1,1,3-trichloroacetone

A technology of trichloroacetone and acetone, which is applied in the field of preparation to improve the synthesis yield of 1,1,3-trichloroacetone, can solve the problems of poor selectivity, low yield, long reaction cycle, etc., and achieve firm loading and high chemical properties Stable, easy-to-storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Add 232.0g (4.0mol) of ultra-pure acetone to a 1000mL reaction flask, slowly add 11.6g of loaded polyamine catalysts under stirring, stir evenly and raise the temperature with a water bath, and wait for the reaction flask to When the temperature is stable at 25°C, start to pass chlorine gas into the reaction bottle for chlorination reaction. The speed of chlorine gas flow is 6.0L / h in the first 1~2h of the reaction, and the speed of 2~6h in the middle stage is 30.0L / h. In the later period of 6-20h, the rate of chlorine gas flow is 6.0L / h. After the chlorine reaction is completed, keep the temperature in the reaction bottle constant and continue to stir for 1-2 hours. After the heat preservation reaction, keep the temperature in the reaction bottle constant, add a certain amount of special solvent into the reaction bottle, and keep stirring for 1 hour. After the stirring was completed, the temperature of the obtained mixture was lowered to 10° C. with ice wat...

Embodiment 2

[0022] Example 2: Add 232.0 g (4.0 mol) of ultra-pure acetone to a 1000 mL reaction flask, slowly add 14.0 g of loaded polyamine catalysts under stirring, stir evenly, and raise the temperature with a water bath, and wait for the reaction flask to When the temperature is stable at 30°C, start to pass chlorine gas into the reaction bottle for chlorination reaction. The speed of chlorine gas flow is 6.0L / h in the first 1~2h of the reaction, and the speed of 2~6h in the middle stage is 32.0L / h. In the later period of 6-18h, the rate of chlorine gas flow is 6.0L / h. After the chlorine reaction is completed, keep the temperature in the reaction bottle constant and continue to stir for 1-2 hours. After the heat preservation reaction, keep the temperature in the reaction bottle constant, add a certain amount of special solvent into the reaction bottle, and keep stirring for 1 hour. After the stirring was completed, the temperature of the obtained mixture was lowered to 10° C. with ic...

Embodiment 3

[0023] Example 3: Add 232.0 g (4.0 mol) of ultra-pure acetone to a 1000 mL reaction flask, slowly add 21.0 g of loaded polyamine catalysts under stirring, stir evenly and raise the temperature with a water bath, and wait for the reaction flask to When the temperature is stable at 30°C, start to pass chlorine gas into the reaction bottle for chlorination reaction. The speed of chlorine gas flow is 8.0L / h in the first 1~2h of the reaction, and the speed of chlorine gas flow in 2~6h in the middle stage is 28.0L / h. In the later period of 6-18 hours, the rate of chlorine gas flow is 8.0L / h. After the chlorine reaction is completed, keep the temperature in the reaction bottle constant and continue to stir for 1-2 hours. After the heat preservation reaction, keep the temperature in the reaction bottle constant, add a certain amount of special solvent into the reaction bottle, and keep stirring for 1 hour. After the stirring was completed, the temperature of the obtained mixture was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com