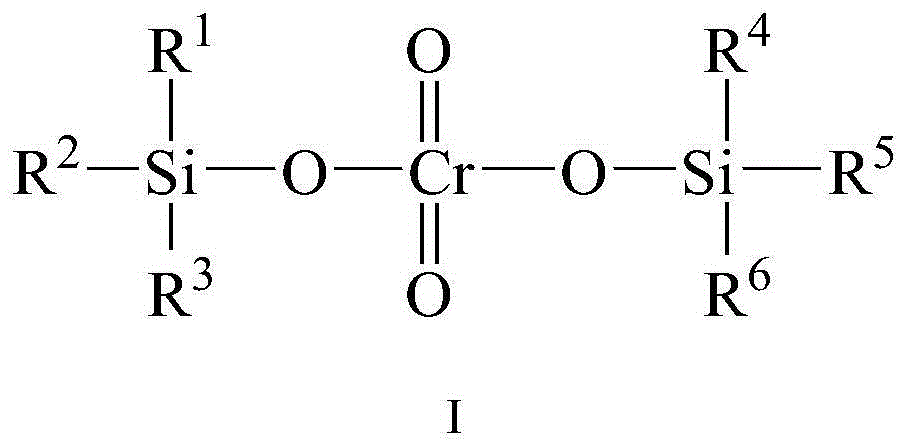

Catalyst component for ethylene polymerization and preparation method thereof

A technology for ethylene polymerization and catalysts, which is applied in the field of supported chromium-based catalyst components, and can solve problems such as aging, poor catalyst preparation stability, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

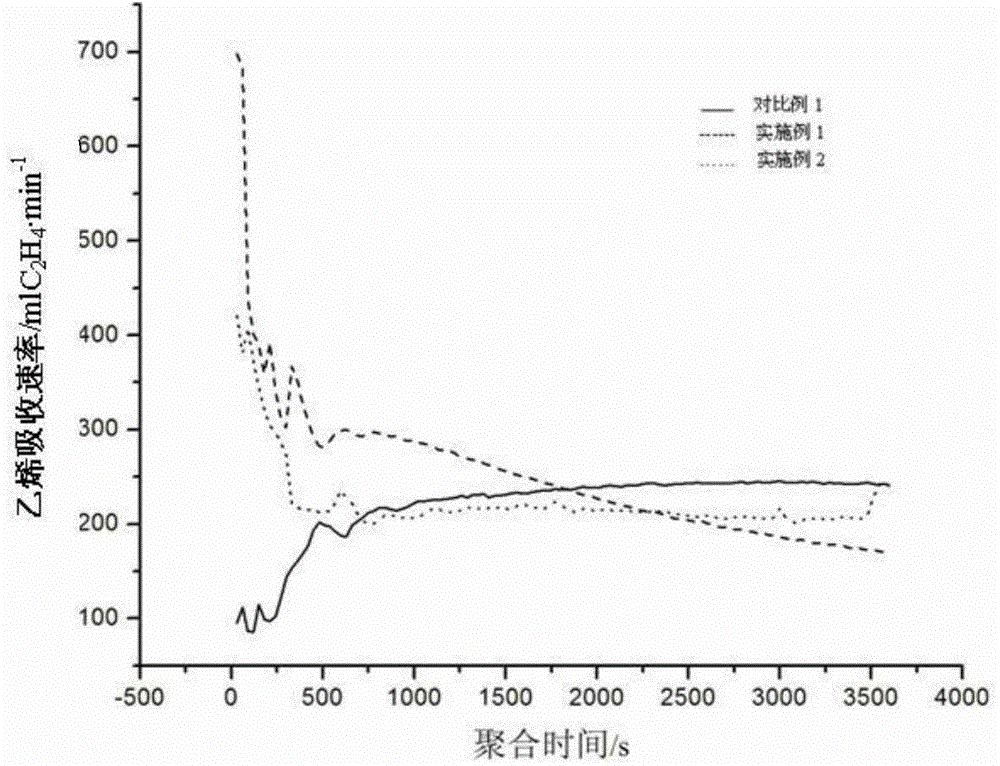

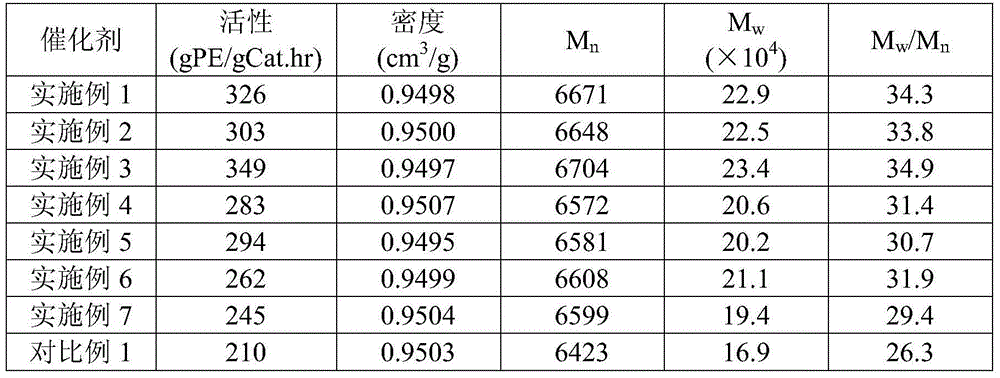

Examples

preparation example Construction

[0042] Preparation of Titanium Magnesium Compounds

[0043] 1. In 150ml of heptane, add 5g (52.6mmol) of magnesium chloride and 34.3g (150mmol) of tetraethoxytitanium, cool under reflux for three hours, filter the mother liquor, and then add 100ml of heptane for recrystallization to obtain 23.6 white crystals of g [Ti 2 (OC 2 h 5 ) 8 Cl] 2 Mg 2 Cl 2 .

[0044] 2. In 150ml of heptane, add 5g (52.6mmol) of magnesium chloride and 51.1g (150mmol) of tetrabutoxytitanium, cool under reflux for three hours, filter the mother liquor, and then add 100ml of heptane for recrystallization to obtain 26.2 white crystals of g [Ti 2 (OC 4 h 9 ) 8 Cl] 2 Mg 2 Cl 2 .

[0045] Preparation of catalyst components

Embodiment 1

[0047] Take 10g of silica gel (W.R.Grece&Co.–Com 955, the pore volume is about 1.1-1.8cm 3 / g, the specific surface area is about 245-375m 2 / g) Dry at 200° C. for 4 hours under nitrogen fluidization. Add 2.6g titanium magnesium compound [Ti 2 (OC 2 h 5 ) 8 Cl] 2 Mg 2 Cl 2 and 0.5 g of bis(triphenylsilyl) chromate, then add 300 ml of hexane, and stir at room temperature to completely dissolve the solid to form a solution. 10 g of dried silica gel was added to the above solution, after stirring, 4 ml (1.3 M) of a hexane solution of diethylethoxyaluminum was added, and after stirring at room temperature, the solvent was removed to obtain a chromium-containing catalyst component. The contents of chromium, titanium, magnesium and aluminum in the catalyst components are listed in Table 1, and the polymerization evaluation results of the catalyst are listed in Table 2.

Embodiment 2

[0049] Except that the addition of bis(triphenylsilyl) chromate was changed from 0.5 g to 0.3 g, the preparation method of the catalyst component was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com