Method for preparing composite polystyrene material for computer

A technology of polystyrene and composite materials, which is applied in the field of preparation of polystyrene composite materials for computers, can solve problems such as computer fires, and achieve the effects of eliminating hidden dangers, good flame retardancy, and reducing residual water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

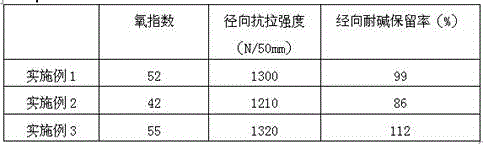

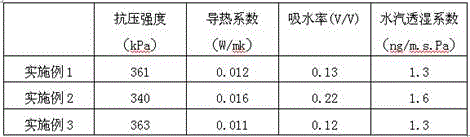

Embodiment 1

[0035] Embodiment 1 A preparation method of polystyrene composite material for computer, comprising the following steps:

[0036] Step 1: Raw material preparation

[0037] A raw material for polystyrene composite materials for computers, in parts by weight, comprising:

[0038] 8 parts of dimethylformamide, 0.3 parts of citrate, 4 parts of artificial stone transparent powder, 3.5 parts of dibutyl phthalate, 0.3 parts of modified soybean protein, 2.5 parts of flame retardant functional additives, 125 parts of polystyrene parts, 5.6 parts of dimethyldichlorosilane, 0.15 parts of diphenyldichlorosilane, 12 parts of nanocellulose powder, and 5 parts of modified mineral powder.

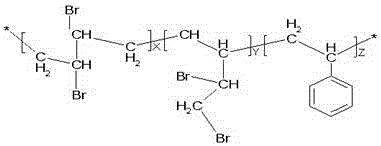

[0039] The flame retardant functional additive is brominated butylbenzene polymer.

[0040] The raw materials for preparing the modified soybean protein include, in parts by weight: 85 parts of defatted soybean protein, 10 parts of casein, 3 parts of lecithin, 36 parts of mung bean starch, 15-20 parts of...

Embodiment 2

[0050] Embodiment 2 A preparation method of polystyrene composite material for computer, comprising the following steps:

[0051] Step 1: Raw material preparation

[0052] A raw material for polystyrene composite materials for computers, in parts by weight, comprising:

[0053] 8 parts of dimethylformamide, 0.5 parts of citrate, 5 parts of artificial stone transparent powder, 3.6 parts of dibutyl phthalate, 0.4 parts of modified soybean protein, 3 parts of flame retardant functional additives, 130 parts of polystyrene parts, 5.7 parts of dimethyldichlorosilane, 0.18 parts of diphenyldichlorosilane, 13 parts of nanocellulose powder, and 6 parts of modified mineral powder.

[0054] The flame retardant functional additive is hexabromocyclododecane;

[0055] The raw materials for the preparation of the modified soybean protein include, in parts by weight: 85 parts of defatted soybean protein, 10 parts of casein, 3 parts of lecithin, 36 parts of mung bean starch, 17 parts of etha...

Embodiment 3

[0065] Embodiment 3 A preparation method of polystyrene composite material for computer, comprising the following steps:

[0066] Step 1: Raw material preparation

[0067] A raw material for polystyrene composite materials for computers, in parts by weight, comprising:

[0068] 9 parts of dimethylformamide, 0.6 parts of citrate, 6 parts of artificial stone transparent powder, 3.8 parts of dibutyl phthalate, 0.6 parts of modified soybean protein, 3.5 parts of flame retardant functional additives, 132 parts of polystyrene parts, 5.8 parts of dimethyldichlorosilane, 0.2 parts of diphenyldichlorosilane, 14 parts of nanocellulose powder, and 7 parts of modified mineral powder.

[0069] The flame retardant functional additive brominated butylbenzene polymer.

[0070] The raw materials for the preparation of the modified soybean protein include, in parts by weight: 85 parts of defatted soybean protein, 10 parts of casein, 3 parts of lecithin, 36 parts of mung bean starch, 20 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com