Low-temperature stress-relief heat treatment process for precision cold-rolled ultra-thin stainless steel strip

A stainless steel strip and stress relief technology, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as easy deformation, and achieve the effects of low cost, guaranteed quality, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

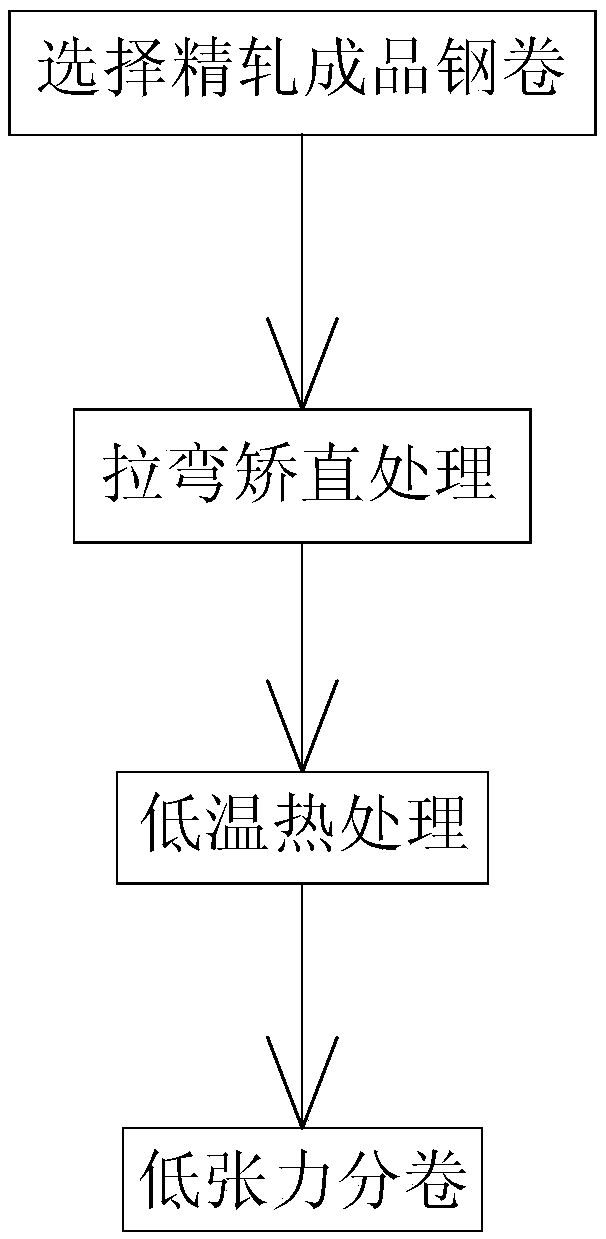

[0020] see figure 1 As shown, in this embodiment, a low-temperature stress-relieving heat treatment process for precision cold-rolled ultra-thin stainless steel strips, the specific processing steps are:

[0021] 1) Select the finished steel coil for finishing rolling: the grade of the selected steel coil is SUS304, the chemical composition: carbon (C) 0.05%, silicon (Si) 0.42%, manganese (Mn) 1.3%, phosphorus (P) 0.045%, sulfur ( S) 0.025%, Nickel (Ni) 8.02%, Chromium (Cr) 18.3%, Copper (Cu) 0.13%, Nitrogen (N) 0.028%, Molybdenum (Mo) 0.01%, after finishing rolling by Sendzimir twenty-high mill The finished precision cold-rolled stainless steel coil has a thickness of 0.15mm, a width of 308mm, a 2D surface, a roughness of Ra0.25-0.35um, and a flatness of 1.0-1.5mm. Its mechanical properties are tensile strength σb≥930Mpa, yield Strength σ0.2≥665Mpa, elongation σ5≥3%, hardness HV310~340;

[0022] 2) Stretch bending straightening treatment: For the finished coils with a thick...

Embodiment 2

[0027] see figure 1 As shown, in this embodiment, a low-temperature stress-relieving heat treatment process for precision cold-rolled ultra-thin stainless steel strips, the specific processing steps are:

[0028] 1) Select the finish-rolled finished steel coil: the selected grade is SUS304, and the chemical composition is the same as in Example 1. Finished precision cold-rolled stainless steel strips and coils that have been finished by the Sendzimir 20-high mill. Its thickness is 0.20mm, width 336mm, surface 2D surface, roughness Ra0.25~0.35um, straightness 0.8~1.0mm, its mechanical properties tensile strength σb≥930Mpa, yield strength σ0.2≥665Mpa, elongation σ5≥3%, hardness HV310~340.

[0029] 2) Stretch bending straightening treatment: For the finished coils with a thickness of 0.20mm, a width of 336mm, and a flatness of 1.0-1.5mm that have been finished rolled by a 20-high rolling mill, a 23-roll stretch-bending straightening machine is used to shape the finished coils. ...

Embodiment 3

[0034] see figure 1 As shown, in this embodiment, a low-temperature stress-relieving heat treatment process for precision cold-rolled ultra-thin stainless steel strips, the specific processing steps are:

[0035] 1) Select the finish-rolled finished steel coil: the selected grade is SUS304, and the chemical composition is the same as in Example 1. Finished precision cold-rolled stainless steel strips and coils that have been finished by the Sendzimir 20-high mill. Its thickness is 0.40mm, width 336mm, surface 2D surface, roughness Ra0.25~0.35um, straightness 1.0~1.5mm, its mechanical properties tensile strength σb≥930Mpa, yield strength σ0.2≥665Mpa, elongation σ5≥3%, hardness HV320~340.

[0036] 2) Stretch bending straightening treatment: For the finished coils with a thickness of 0.40 mm, a width of 336 mm, and a flatness of 1.0 to 1.5 mm that have been finished rolled by a 20-high rolling mill, a 23-roll stretch bending straightening machine is used to carry out the plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com