Aluminum profile surface treatment bath solution stability control system and control method thereof

A technology of stability control and surface treatment, applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problem of insufficient water control time, affecting the composition of the next bath, increasing the water consumption per ton of material added by drugs, etc. problems, to achieve accurate control of water control time, facilitate waste liquid treatment, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

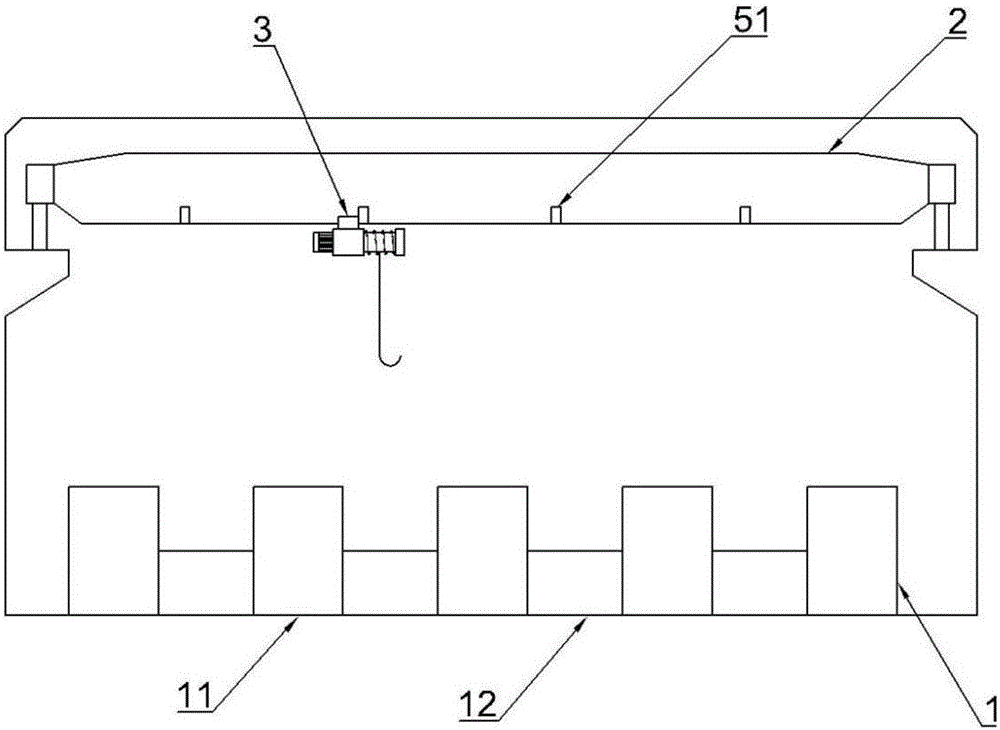

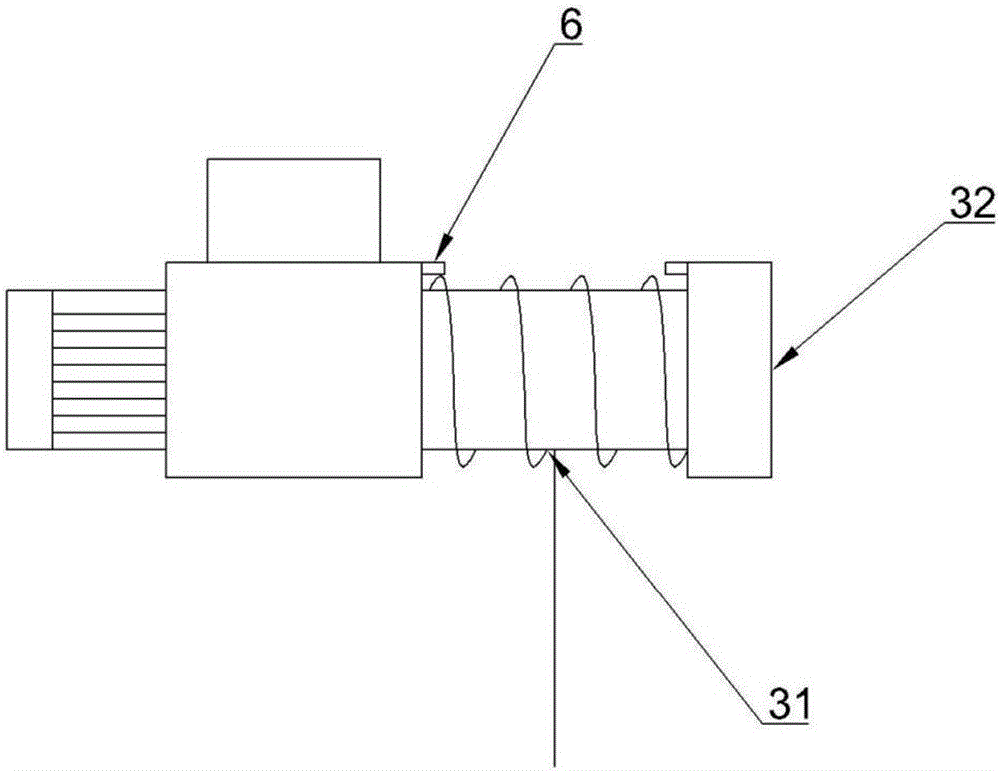

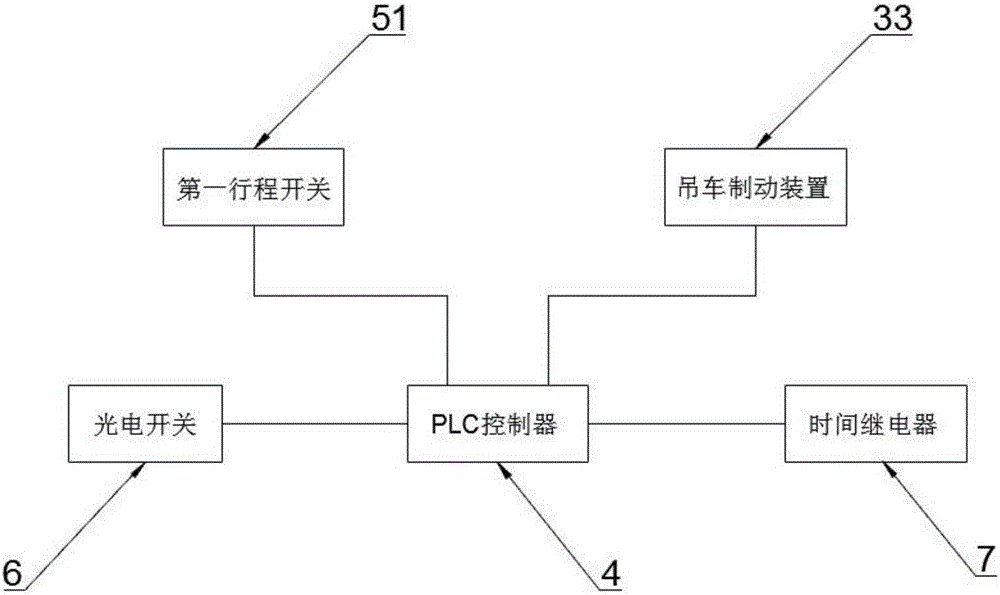

[0034] Such as Figures 1 to 3 As shown, an aluminum profile surface treatment bath stability control system of the present invention includes a surface treatment system 1 composed of a plurality of process tanks 11 arranged in a straight line in sequence, and a trolley track 2 arranged in parallel above the surface treatment system 1 , and the crane 3 driven by the power mechanism that can walk on the trolley track 2, the crane braking device 33 that can stop the crane 3 on the trolley track 2, also includes a PLC controller 4, every two processes Also be provided with waste liquid tank 12 between groove 11, also be provided with the first travel switch 51 to determine the stop position of crane 3 on the trolley track 2, the first travel switch 51 is positioned at waste liquid tank 12 tops, and PLC controller 4 communicates with respectively The crane brake device 33, the first travel switch 51 and the time relay 7 are connected, the trolley track 2 is a single beam bridge ty...

Embodiment 2

[0042] Such as Figures 3 to 5 As shown in the present invention, a kind of aluminum profile surface treatment tank liquid stability control system, the trolley track 2 is a double-girder bridge type, and the two ends of the crane 3 are slidably arranged above the double-girder track, and the crane 3 is driven by a power mechanism. Walking on the girder bridge track, the crane 3 lifts the aluminum profile in the middle of the double beam track through the flexible member 31, the first travel switch 51 is a normally closed switch and is set on the outer side of the upper end of the trolley track 2 near the crane 3, the first travel switch When 51 is not working, it does not hinder the crane 3 from walking along the trolley track 2.

[0043] The other structures of the second embodiment are the same as those of the first embodiment, and the working methods are also the same, so no more details are given here.

Embodiment 3

[0045] Such as Image 6 , 7 As shown, on the basis of Example 1, a system for controlling the stability of the bath liquid for surface treatment of aluminum profiles of the present invention also includes two parallel cart tracks 8, and the two ends of the trolley rails 2 are respectively slidably arranged on the two large cart tracks. on the trolley track 8, and the trolley track 2 is driven by the power mechanism to walk on the trolley track 8, and the trolley track 2 is controlled by the trolley track braking device 21 and can stop on the trolley track 8. The system includes multiple 2 arranged surface treatment systems 1, a waste liquid tank 13 is arranged between every two surface treatment systems 1, and a second travel switch 52 for determining the stop position of the trolley track 2 is also arranged on the cart track 8, the second travel switch 52 is located on the cart track 8 parallel to the top of the waste liquid tank 13, the second travel switch 52 and the troll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com