A kind of dense ash-packed general anesthesia cigarette paper and its preparation method

A cigarette paper and densification technology, applied in pulp beating method, paper, papermaking, etc., can solve problems affecting normal production, difficulty in beating hemp pulp fibers, and raising manufacturing costs, so as to improve the ash wrapping effect and enhance the sensory taste , The effect of raising manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

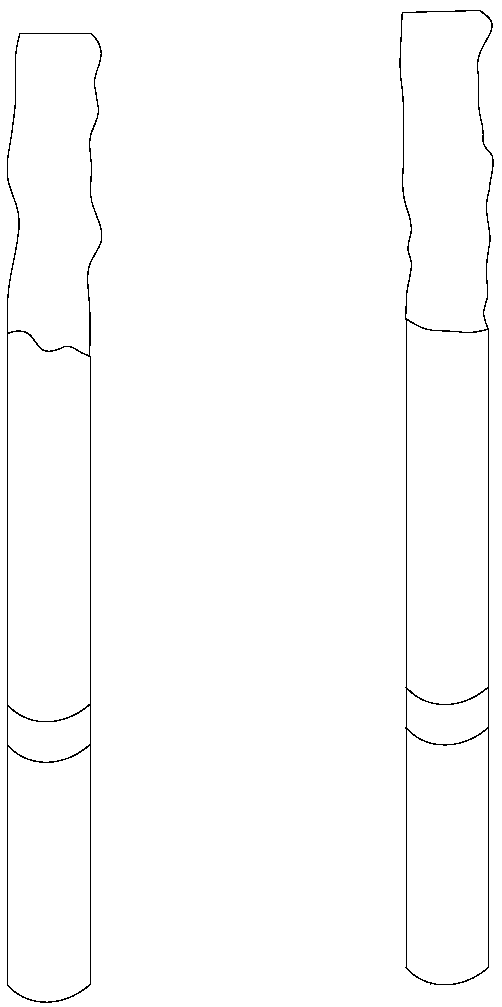

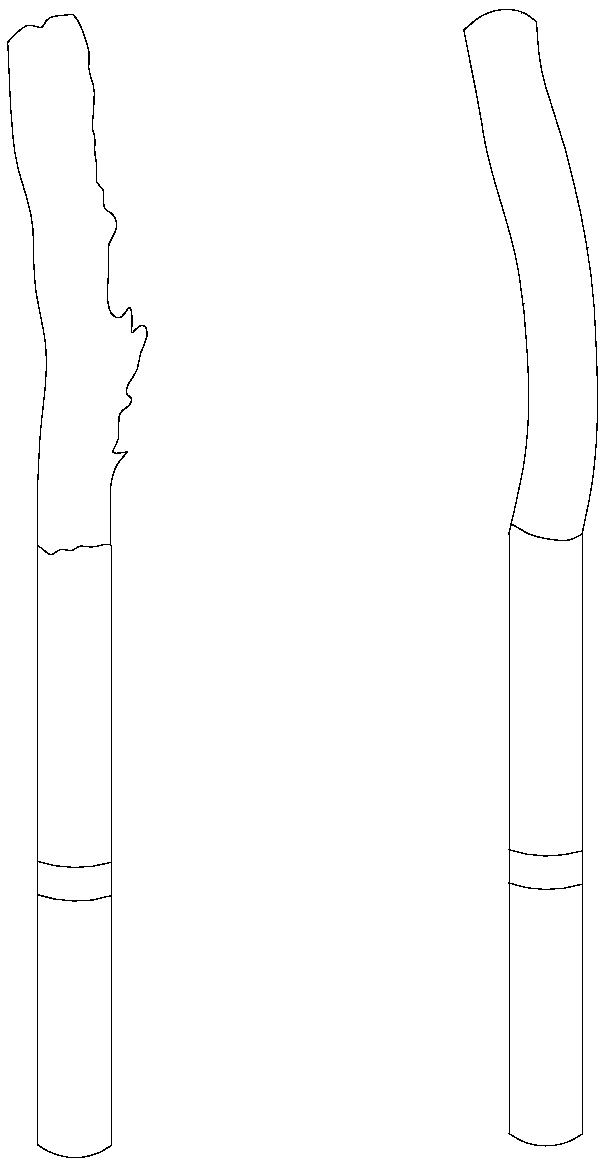

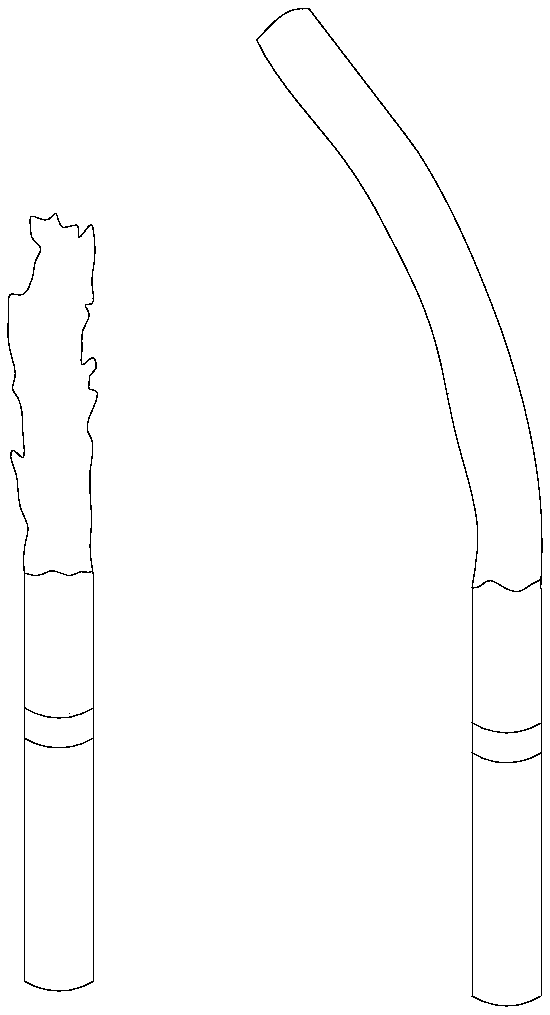

Image

Examples

Embodiment 1

[0034]Get 3000m3 of the hemp pulp fiber solution through cutting, the concentration is 3%, beating in the mode of fiber cutting, the degree of beating is controlled at 40°SR, and the wet weight is controlled at about 17g; Get 7000m3 of the hemp pulp fiber solution through cutting, The concentration is 3%, and the beating method is mainly chopped and divided, and the beating degree is controlled at 80°SR, and the wet weight is controlled at about 7.5g; add the above two kinds of slurries to 3500Kg liquid calcium carbonate and stir to mix evenly ; Add 1.1m3 water to dissolve 10kg of potassium and sodium salts of the combustion enhancer to prepare a combustion enhancer solution, then add 4kg of dust-coating agent to the prepared combustion enhancer solution, stir well, and use spraying to add on both sides . Cigarette paper is produced according to the conventional papermaking process, and the index of cigarette paper is controlled on the equipment to be quantitative: 28g / m2, air...

Embodiment 2

[0036] Get 4000m of the hemp pulp fiber solution through cutting, the concentration is 3%, beating in the form of fiber cutting, the beating degree is controlled at 40°SR, and the wet weight is controlled at about 17g; Get 6000m of the hemp pulp fiber solution through cutting, The concentration is 3%, and the beating method is mainly chopped and divided, and the beating degree is controlled at 80°SR, and the wet weight is controlled at about 7.5g; add the above two kinds of slurries to 3500Kg liquid calcium carbonate and stir to mix evenly ; Add 1.1m3 water to dissolve 10kg of potassium and sodium salts of the combustion enhancer to prepare a combustion enhancer solution, then add 4kg of dust-coating agent to the prepared combustion enhancer solution, stir well, and use spraying to add on both sides . Cigarette paper is produced according to the conventional papermaking process, and the index of cigarette paper is controlled on the equipment to be quantitative: 32g / m2, air per...

Embodiment 3

[0038] Get 5000m of hemp pulp fiber solution through cutting, the concentration is 3%, beating in the mode of fiber cutting, beating degree is controlled at 40 ° SR, and wet weight is controlled at about 17g; Get 5000m of hemp pulp fiber solution through cutting, The concentration is 3%, and the beating method is mainly chopped and divided, and the beating degree is controlled at 80°SR, and the wet weight is controlled at about 7.5g; add the above two kinds of slurries to 3500Kg liquid calcium carbonate and stir to mix evenly ; Add 1.1m3 water to dissolve 10kg of potassium and sodium salts of the combustion enhancer to prepare a combustion enhancer solution, then add 4kg of dust-coating agent to the prepared combustion enhancer solution, stir well, and use spraying to add on both sides . Cigarette paper is produced according to the conventional papermaking process, and the index of cigarette paper is controlled on the equipment to be quantitative: 37g / m2, air permeability: 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com