Cigarette paper containing hyaluronic acid and preparation method of cigarette paper

A technology of hyaluronic acid and cigarette paper, which is applied in the biological field, can solve the problems of not much benefit to human health, physical harm, and single effect, so as to reduce the probability of cancer and cardiovascular and cerebrovascular diseases, reduce processing loss, and improve health care. Moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing cigarette paper containing hyaluronic acid, comprising the following steps:

[0056] Take the roll paper raw material for stirring, mixing and filtering to make the papermaking raw material;

[0057] Additives are obtained by dissolving combustion aids, defoamers, and preservatives in water;

[0058] Prepare an aqueous hyaluronic acid solution, which is equally divided into two parts, and vitamins and tea polyphenols are added to each part respectively to obtain a hyaluronic acid aqueous solution containing vitamins and a hyaluronic acid aqueous solution containing tea polyphenols;

[0059] Adding the additive to the papermaking raw material, then adding the vitamin-containing hyaluronic acid aqueous solution, and mixing uniformly to obtain a papermaking raw pulp;

[0060] The papermaking raw pulp is dried, calendered, and rolled to make base paper;

[0061] The hyaluronic acid aqueous solution containing tea ...

Embodiment 1

[0067] Take 80g of bleached hemp pulp and stir and filter to obtain fine and uniform papermaking raw materials. 1g of potassium citrate, 1g of sodium citrate, 0.08g of fumaric acid and 0.01g of polydimethylsiloxane were weighed and dissolved in 15g of deionized water to make additives for use. Dissolve 0.05g of sodium hyaluronate (molecular weight: 1000KDa) in 15g of deionized water and stir evenly to obtain a sodium hyaluronate aqueous solution, which is equally divided into two sodium hyaluronate aqueous solutions, and 0.08g of vitamin C is added to one of them and stirred Evenly make it fully dissolved, add 0.06g tea polyphenols to the other half and stir evenly for later use.

[0068] Add the additive prepared above to the papermaking raw material, and then add the sodium hyaluronate aqueous solution containing vitamin C three times uniformly, and stir while adding until the papermaking raw pulp is obtained evenly. Then the raw paper pulp is dried, calendered, and rolled ...

Embodiment 2

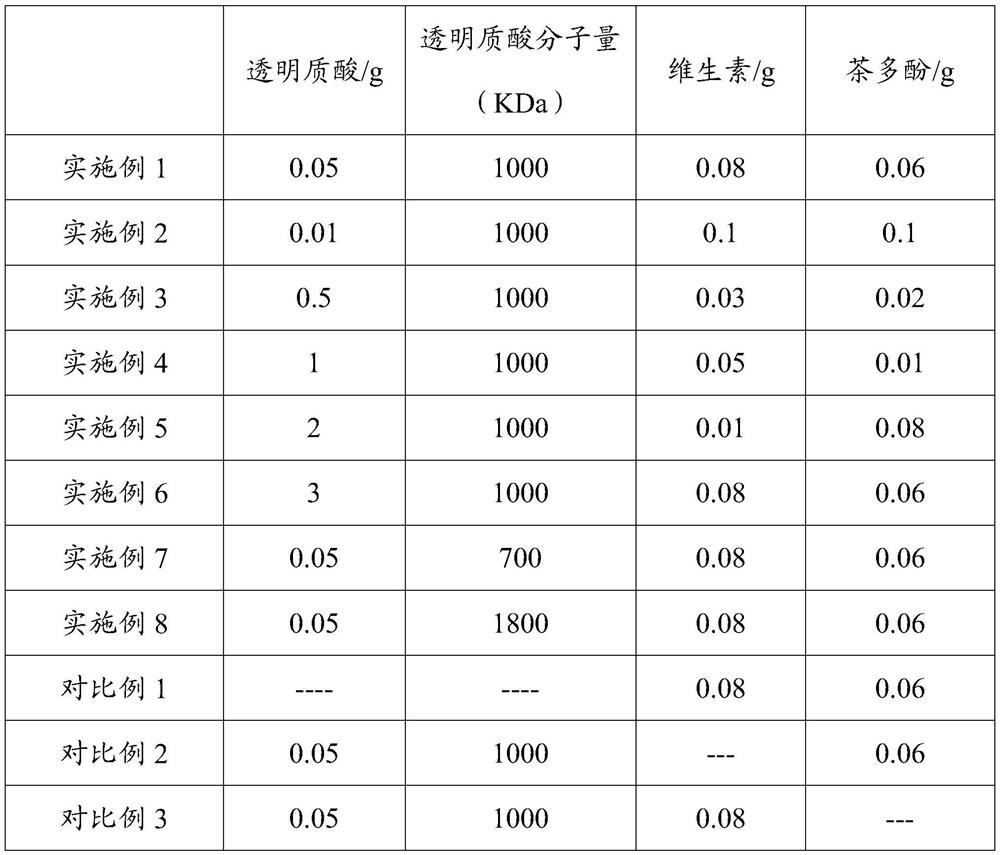

[0070] The difference between Example 2 and Example 1 is that the amounts of hyaluronic acid, vitamins and tea polyphenols added are different, specifically as shown in Table 1, the amounts and operations of other components and the steps of preparing cigarette paper are the same as in Example 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com