Method of adding graphene to improve elastic modulus of paper

A technology of elastic modulus and graphene, which is applied in the manufacturing process of adding graphene to increase the elastic modulus of paper, which can solve the problems of ordinary composite paper with low elastic modulus and unable to meet specific needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

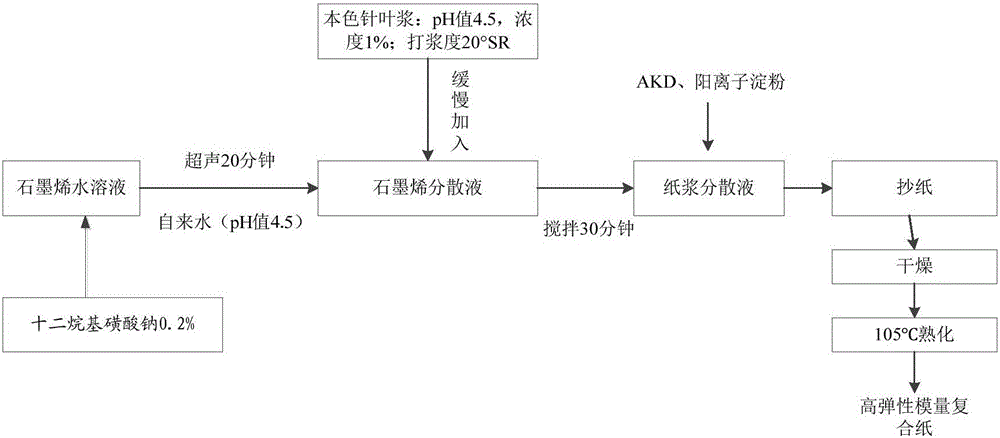

[0032] figure 1 A process flow diagram according to one embodiment of the present invention is shown. The method comprises: beating the natural color coniferous pulp with a concentration of 1% to about 20 ° SR (Shore beating degree), for subsequent use; adding 1 weight part of graphene aqueous solution to tap water under stirring, so that the graphene concentration is about If it is 0.5%, add 0.2% sodium dodecylsulfonate as a dispersant, and ultrasonically disperse for 20 minutes. Take 100 parts by weight of pulp, dilute it to about 0.5%, slowly add it into the graphene aqueous solution, stir for 30 minutes, add 0.5% alkyl ketene dimer (AKD) and 1% cationic starch, and stir evenly. Papermaking on the machine, dehydration, drying, aging at about 105°C for about 30 minutes after getting off the machine, to obtain graphene composite paper with high elastic modulus.

Embodiment 2

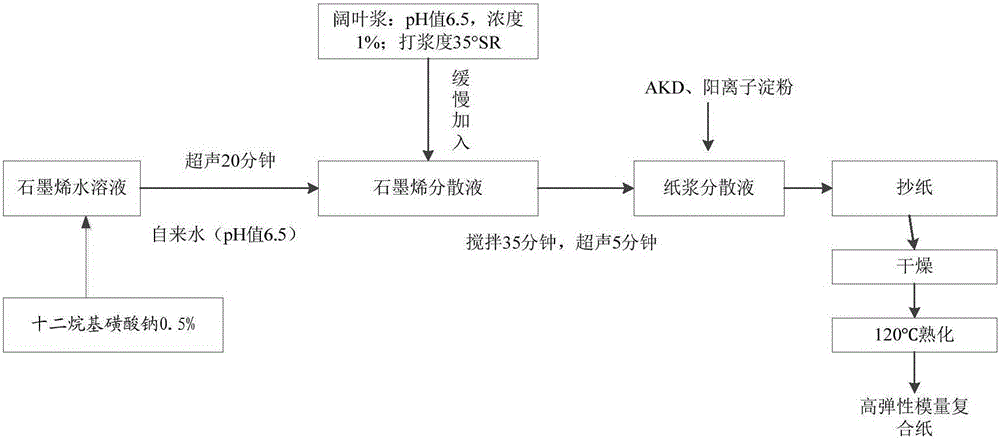

[0034] figure 2 A process flow diagram according to one embodiment of the present invention is shown. The method comprises: beating the broad-leaf pulp with a concentration of 1% to about 35 ° SR (Shore beating degree), for subsequent use; adding 1 weight part of graphene aqueous solution to tap water under stirring, so that the graphene concentration is about 1%, add 0.5% sodium dodecylsulfonate as a dispersant, and ultrasonically disperse for 20 minutes. Get 100 parts by weight of pulp, dilute it to about 0.5%, slowly add it to the graphene aqueous solution, stir for 35 minutes, ultrasonically disperse for 5 minutes, add 0.5% alkyl ketene dimer (AKD) and 1% cationic starch, Stir well. Papermaking on the machine, dehydration, drying, aging at about 120°C for about 30 minutes after getting off the machine, to obtain graphene composite paper with high elastic modulus.

Embodiment 3

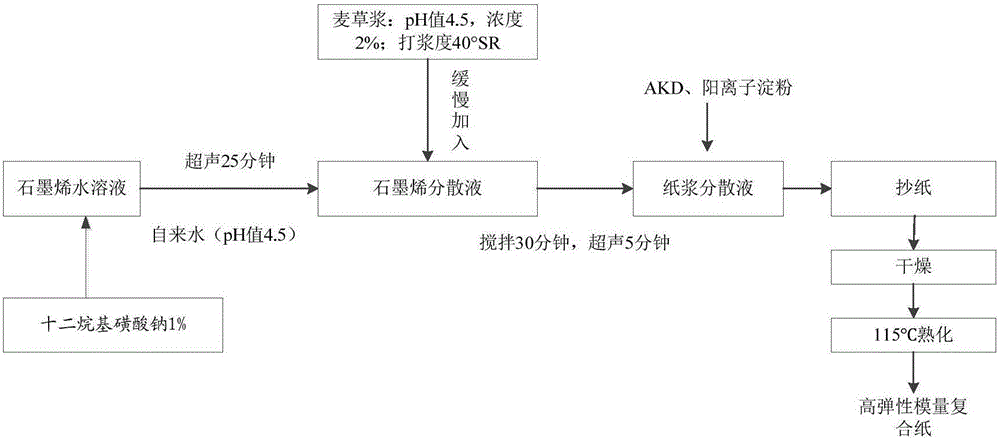

[0036] image 3 A process flow diagram according to one embodiment of the present invention is shown. The method comprises: beating the wheat straw pulp with a concentration of 2% to about 40 ° SR (Shore degree of beating), for subsequent use; adding 3 parts by weight of graphene aqueous solution to tap water under stirring, so that the concentration of graphene is about 1 %, add 1% sodium dodecylsulfonate as a dispersant, and ultrasonically disperse for 25 minutes. Get 100 parts by weight of pulp, dilute it to about 0.5%, slowly add it to the graphene aqueous solution, stir for 30 minutes, ultrasonically disperse for 5 minutes, add 0.5% alkyl ketene dimer (AKD) and 1% cationic starch, Stir well. Papermaking on the machine, dehydration, drying, aging at about 115°C for about 30 minutes after getting off the machine, to obtain graphene composite paper with high elastic modulus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com