Coal gas power generation system for steel mills

A power generation system and gas technology, which is applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve the problems of low gas utilization efficiency, long construction period, and large engineering volume, so as to improve gas utilization efficiency and work ability , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

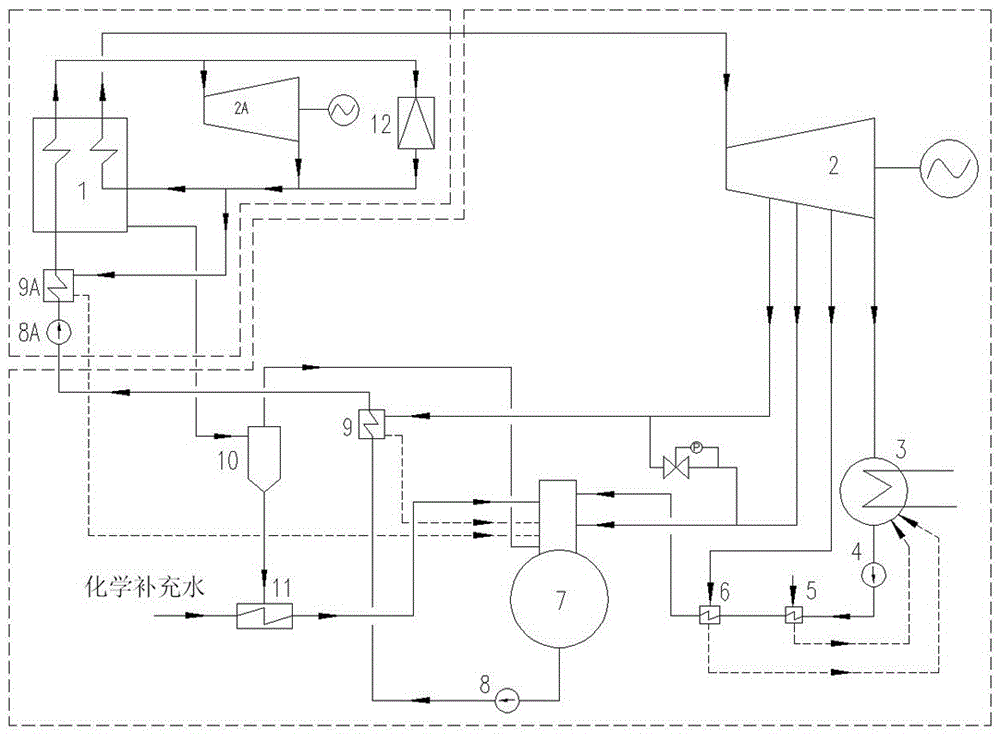

[0028] As shown in the figure, the specific implementation method is as follows:

[0029] A system for generating electricity with steel plant gas, including a turbogenerator set 2, a condenser 3, a condensate pump 4, a seal heater 5, a low-pressure heater 6, a deaerator 7, a feed water pump 8 and a primary The low-voltage power generation system composed of the high-pressure heater 9 and the sewage system mainly composed of the sewage expansion vessel 10 and the sewage heater 11 also include the gas boiler 1 and the high-voltage power generation system mainly composed of the back pressure turbine generator set 2A, the gas boiler The steam produced by 1 enters the back pressure turbo-generator unit 2A through pipelines for high-pressure power generation, part of the steam discharged from the back-pressure turbo-generator unit 2A enters the secondary high-pressure heater 9A to heat the boiler feed water, and the other part directly passes through the gas-fired boiler 1 After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com