Biomass burning device

A combustion device and biomass technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of smoke and dust emission, single structure, low thermal efficiency, etc., achieve improved combustion efficiency, reasonable and simple structure design, and low smoke and dust emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

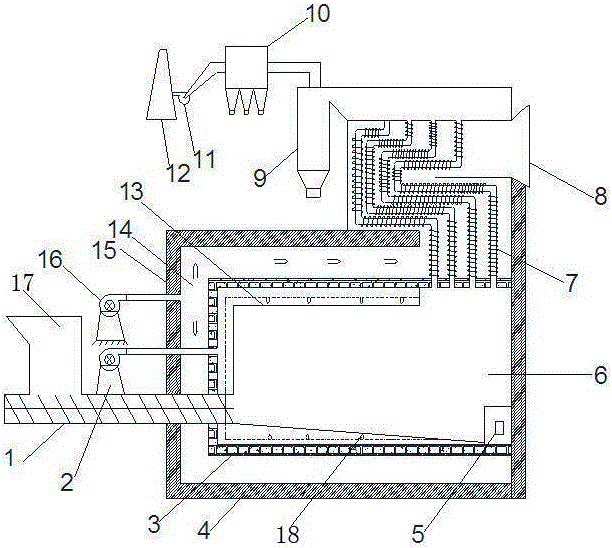

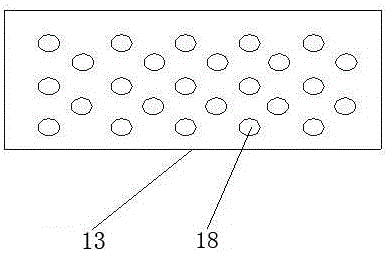

[0012] Such as figure 1 Shown, a kind of biomass burning device comprises the furnace body 4 that forms furnace 6, is provided with feed inlet on one side of furnace body 4, is provided with ash discharge port 5 on the other side of furnace body 4, and furnace body 4 The furnace wall includes an inner wall 13, a heat-insulating furnace layer 3 and an outer wall 15 arranged sequentially from the inside to the outside. The inner wall 13 is arranged in contact with the heat-insulating furnace layer 3, and forms Cold wind passage 14, cold wind passage 14 is connected with the cooling air blower 16 that is located at body of heater 4 outside, and is connected with the outside world by the hot blast pipe 8 that is located at cold wind passage exit on the cold wind passage outlet and is located on the outer wall 15; It is communicated with the finned tube heat exchanger 7 extending into the hot blast pipe 8, the outlet of the finned tube heat exchanger 7 is opened on the side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com