One-chip type quartz resonance pressure/temperature sensor and technological method therefor

A temperature sensor, monolithic technology, applied in thermometers, thermometers using electric/magnetic elements that are directly sensitive to heat, measurement of properties and forces using piezoelectric devices, etc., can solve difficult process, resonant quartz crystal Problems such as large volume of pressure/temperature sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

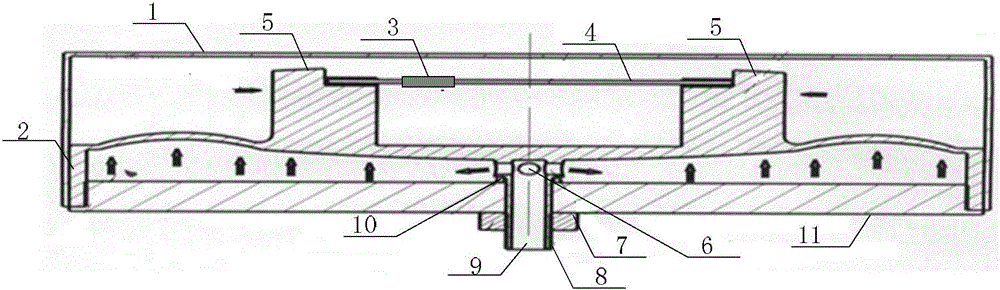

[0031] Specific implementation mode 1. Combination figure 1 Describe this embodiment, the monolithic quartz resonant pressure / temperature sensor described in this embodiment includes a pressure-compression force converter, a sensor housing 1, a monolithic heat-sensitive resonator 3, and a monolithic force-sensitive sensor 4 , reference pressure column 8, pressure port 9 and base 11;

[0032] The pressure-compression force transducer includes two pressure conducting columns 5 and a pressure guiding elastic diaphragm 2;

[0033] The lower ends of the two pressure conducting columns 5 are fixed on the upper surface of the pressure guiding elastic diaphragm 2, and form an integral part with the pressure guiding elastic diaphragm 2;

[0034] The reference pressure column 8 is a hollow tubular structure with a stepped gap at the top, and the bottom end of the reference pressure column 8 is a pressure port 9;

[0035]The top of the reference pressure column 8 is fixed on the lower ...

specific Embodiment approach 2

[0060] Specific Embodiment 2. This embodiment is a further description of the monolithic quartz resonant pressure / temperature sensor described in Specific Embodiment 1. It also includes a sealing ring 10, which is sleeved on the reference pressure column 8 On the column, and between the four circular through holes 6 on the reference pressure column 8 and the base 11 .

specific Embodiment approach 3

[0061] Specific embodiment three. This embodiment is a further description of the monolithic quartz resonant pressure / temperature sensor described in specific embodiment one. The lower part of the reference pressure column 8 is provided with an external thread, and the lower part of the reference pressure column 8 is threaded with the sealing nut. connect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com