Evaluation method for polymerization performance of color coated plate organic coating

An organic coating and evaluation method technology, which is applied in the field of steel anticorrosion, can solve the problems of long test cycle, affecting the efficiency of product performance evaluation, and large impact on grade evaluation, so as to shorten the test cycle, improve the efficiency of performance evaluation, and avoid the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated by some examples below.

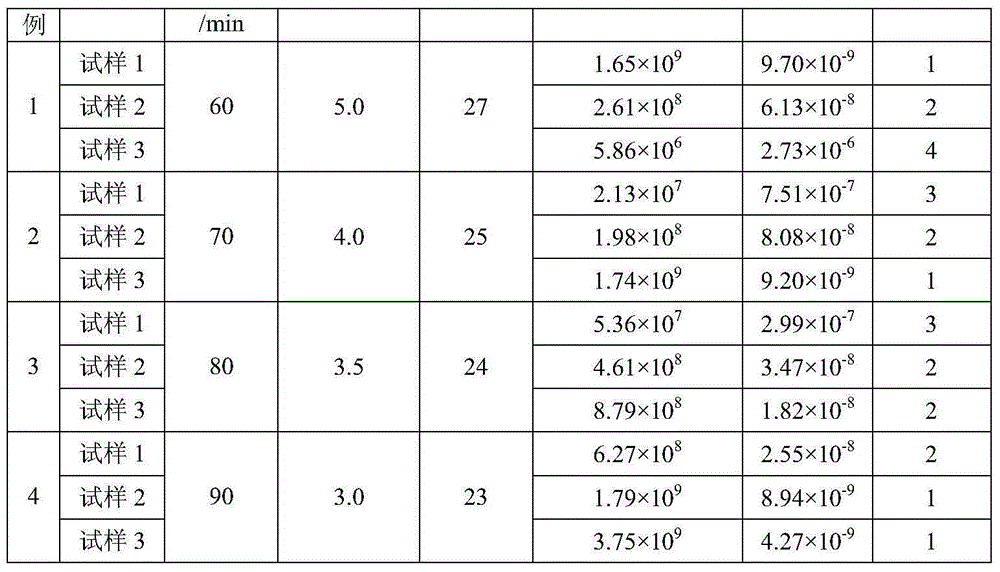

[0020] Select the color-coated steel plate as the test sample, and make sample 1, sample 2 and sample 3 according to the requirements of size 150mm*75mm. Select different pretreatment time and electrolyte concentration to process the sample, take out the sample after processing and perform electrochemical AC impedance spectroscopy test according to different test conditions, and use ZSimpWin software to analyze the impedance spectrum data, and calculate the characteristic electrochemical parameters The porosity of the organic coating of the color-coated board, according to the porosity of the organic coating, the polymerization performance level of the organic coating is divided. The test conditions, calculation results and grade evaluation results are shown in Table 2. At the same time, the test samples were subjected to the routine performance testing of the organic coating of the color-coated boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com