Positive electrode material and battery

A positive electrode material and battery technology, applied in the direction of battery electrodes, lead-acid batteries, lead-acid battery construction, etc., can solve the problems of battery cycle life reduction, battery gas generation, battery self-discharge, etc., to reduce battery self-discharge and inhibit performance The effect of attenuation and avoidance of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

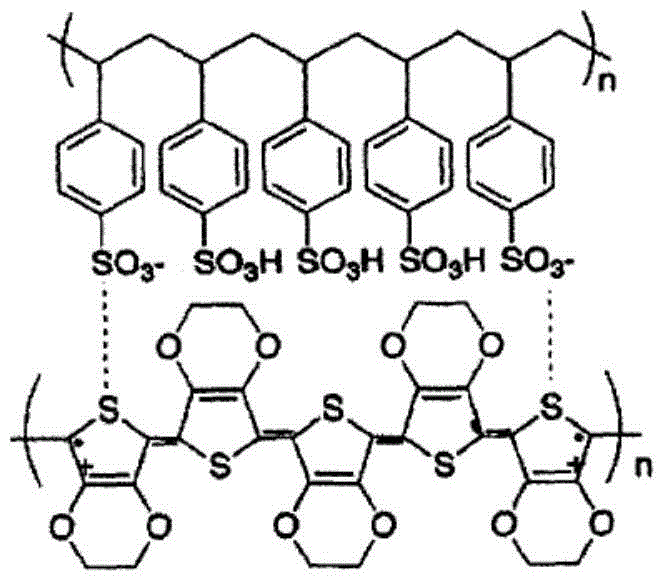

[0094] The positive electrode active material lithium manganate, the conductive polymer poly 3,4-ethylenedioxythiophene-polystyrene sulfonic acid (PEDOT-PSS, Baytron P), the binder CMC and SBR according to the mass ratio LMO:PEDOT- PSS:CMC:SBR=86.5:10:1:2.5 is mixed in water to form a uniform positive electrode slurry. The positive electrode slurry was coated on the positive electrode current collector graphite foil to form an active material layer, which was then pressed into an area of 1 cm 2 of discs.

[0095] Zinc foil is used as the negative electrode, and AGM film is used as the diaphragm.

[0096] Weigh a certain mass of zinc sulfate and lithium sulfate, add them to dissolve in water, and configure an electrolyte solution with a concentration of zinc sulfate of 2 mol / L and a concentration of lithium sulfate of 1 mol / L.

[0097] Assemble the positive electrode, negative electrode and separator into a battery cell, put it into the casing, then inject electrolyte, seal...

Embodiment 2

[0099] Mix the positive electrode active material lithium manganate, conductive agent PEDOT-PSS and graphite KS6, binder CMC and SBR in water according to the mass ratio LMO:conductive agent:CMC:SBR=86.5:10:1:2.5 to form a uniform positive electrode Slurry, wherein, the mass ratio of PEDOT-PSS and KS6 is 1:9. The remaining composition and preparation method of the battery are the same as in Example 1.

Embodiment 3

[0101] Mix the positive electrode active material lithium manganate, conductive agent PEDOT-PSS and graphite KS6, binder CMC and SBR in water according to the mass ratio LMO:conductive agent:CMC:SBR=86.5:10:1:2.5 to form a uniform positive electrode Slurry, wherein, the mass ratio of PEDOT-PSS and KS6 is 1:5.

[0102] The remaining composition and preparation method of the battery are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com