Electric brush for train set grounding backflow device

A technology for backflow devices and EMUs, applied in the direction of circuits, connections, collectors, etc., can solve the problems of low resistivity, good lubricity, and long service life of brushes, and achieve low raw material resistivity, high PV characteristics, and long life. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

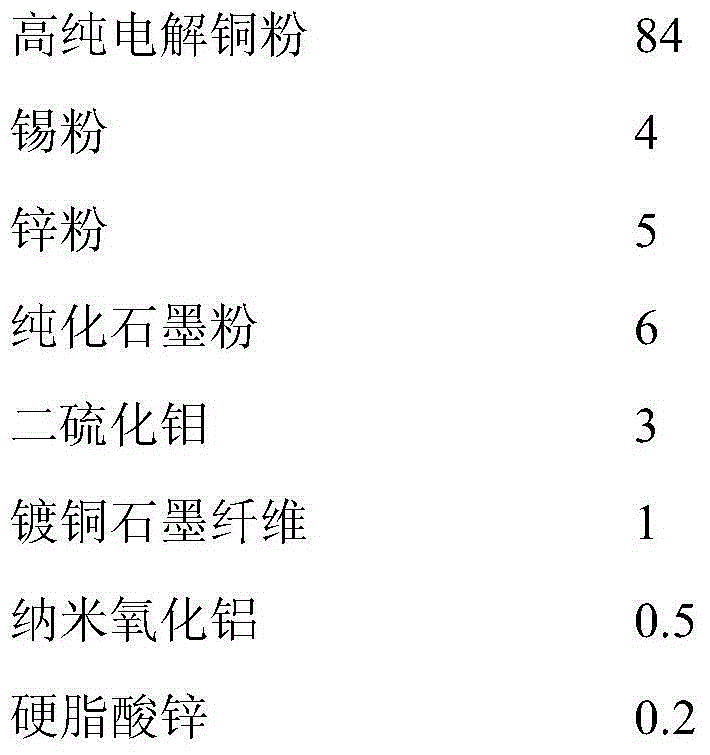

[0074] 1. Raw material preparation

[0075] Raw materials are prepared according to the following proportions by weight:

[0076]

[0077] 2. Prepare the premix

[0078] At room temperature, add the prepared high-purity electrolytic copper powder, tin powder, zinc powder, purified graphite powder, molybdenum disulfide and copper-coated graphite fiber into the V-shaped mixer, and mix for 30 minutes with the cover closed to prepare the first pre-prepared mix;

[0079] Then spray the nano-alumina alcohol solution (25% by mass fraction) into the mixed first mixture, close the lid and mix for 60 minutes to obtain the second premix;

[0080] Finally, the zinc stearate was added to the mixed second mixture, and the lid was closed and mixed for 60 minutes to prepare the premix.

[0081] 3. Drying treatment

[0082] The premixed material was placed in a vacuum drying oven and dried at 30° C. for 2 h to remove the liquid substances therein.

[0083] 4. Compression treatment

[...

Embodiment 2

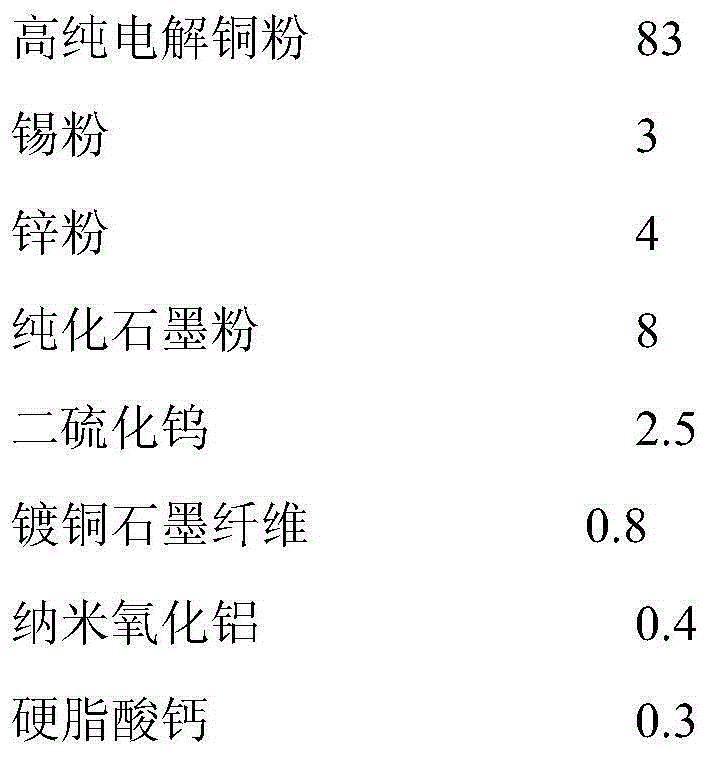

[0094] 1. Raw material preparation

[0095] Raw materials are prepared according to the following proportions by weight:

[0096]

[0097] 2. Prepare the premix

[0098] At normal temperature, add the prepared high-purity electrolytic copper powder, tin powder, zinc powder, purified graphite powder, molybdenum disulfide and copper-coated graphite fiber into the V-type mixer, and mix for 35 minutes with the cover closed to prepare the first pre-prepared mix;

[0099] Then spray the nano-alumina alcohol solution (25% by mass fraction) into the mixed first mixture, close the lid and mix for 70 minutes to obtain the second premix;

[0100] Finally, the zinc stearate was added into the mixed second mixture, and the lid was closed and mixed for 50 minutes to prepare the premix.

[0101] 3. Drying treatment

[0102] The premix was placed in a vacuum drying oven, and dried at 25° C. for 2.5 hours to remove the liquid substances therein.

[0103] 4. Compression treatment

[01...

Embodiment 3

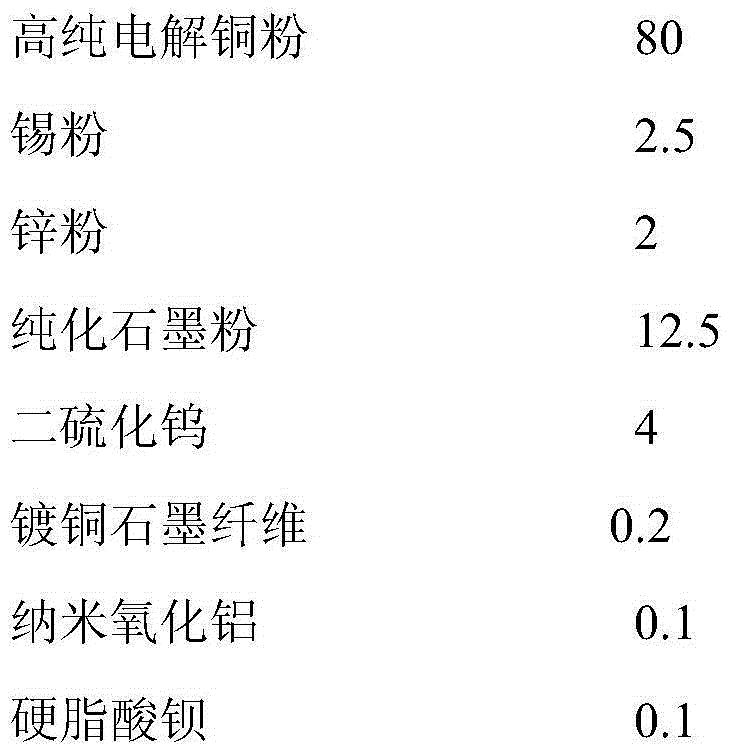

[0114] 1. Raw material preparation

[0115] Raw materials are prepared according to the following proportions by weight:

[0116]

[0117] 2. Prepare the premix

[0118] At room temperature, add the prepared high-purity electrolytic copper powder, tin powder, zinc powder, purified graphite powder, molybdenum disulfide and copper-coated graphite fiber into the V-type mixer, and mix for 40 minutes with the cover closed to obtain the first pre-prepared mix;

[0119] Then spray the nano-alumina alcohol solution (25% by mass fraction) into the mixed first mixture, close the lid and mix for 80 minutes to obtain the second premix;

[0120] Finally, the zinc stearate was added to the mixed second mixture, and the lid was closed and mixed for 40 minutes to prepare the premix.

[0121] 3. Drying treatment

[0122] The premix was placed in a vacuum drying oven, and dried at 20° C. for 3 h to remove the liquid substances therein.

[0123] 4. Compression treatment

[0124] The dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com