A kind of material used to prepare the brush for grounding return device of EMU

A technology of backflow device and grounding brush, which is applied in the field of material science to achieve excellent lubricity, low friction coefficient, and prevent the increase of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Raw material preparation

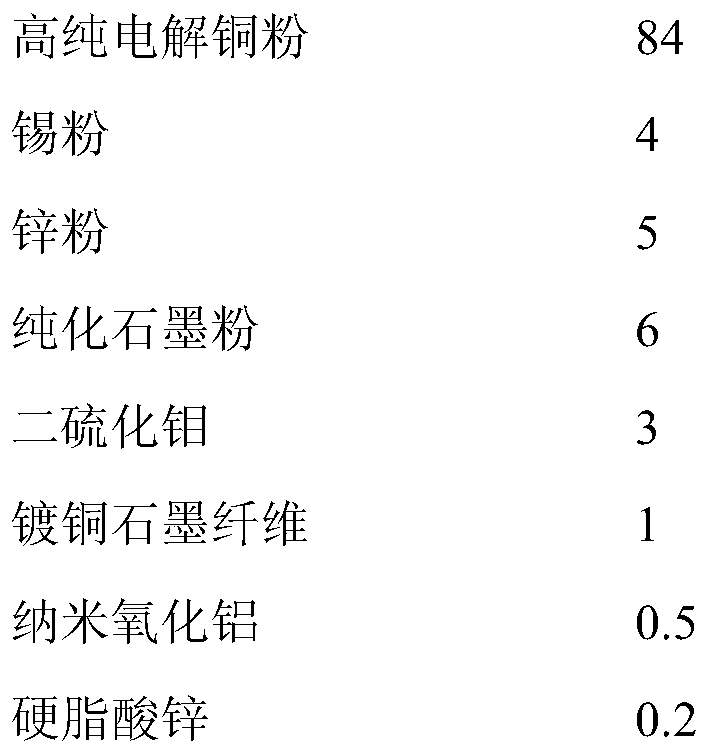

[0048] Raw materials are prepared according to the following proportions by weight:

[0049]

[0050] 2. Prepare the premix

[0051] At room temperature, add the prepared high-purity electrolytic copper powder, tin powder, zinc powder, purified graphite powder, molybdenum disulfide and copper-coated graphite fiber into the V-shaped mixer, and mix for 30 minutes with the cover closed to prepare the first pre-prepared mix;

[0052] Then spray the nano-alumina alcohol solution (25% by mass fraction) into the mixed first mixture, close the lid and mix for 60 minutes to obtain the second premix;

[0053] Finally, the zinc stearate was added to the mixed second mixture, and the lid was closed and mixed for 60 minutes to prepare the premix.

[0054] 3. Drying treatment

[0055] The premixed material was placed in a vacuum drying oven and dried at 30° C. for 2 h to remove the liquid substances therein.

[0056] 4. Compression treatment

[...

Embodiment 2

[0067] 1. Raw material preparation

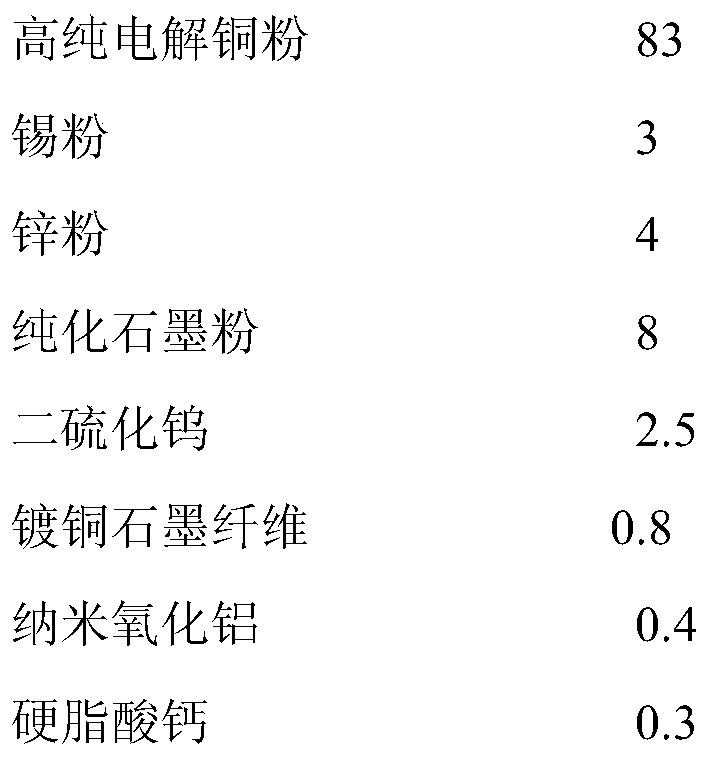

[0068] Raw materials are prepared according to the following proportions by weight:

[0069]

[0070] 2. Prepare the premix

[0071] At normal temperature, add the prepared high-purity electrolytic copper powder, tin powder, zinc powder, purified graphite powder, molybdenum disulfide and copper-coated graphite fiber into the V-type mixer, and mix for 35 minutes with the cover closed to prepare the first pre-prepared mix;

[0072] Then spray the nano-alumina alcohol solution (25% by mass fraction) into the mixed first mixture, close the lid and mix for 70 minutes to obtain the second premix;

[0073] Finally, the zinc stearate was added into the mixed second mixture, and the lid was closed and mixed for 50 minutes to prepare the premix.

[0074] 3. Drying treatment

[0075] The premix was placed in a vacuum drying oven, and dried at 25° C. for 2.5 hours to remove the liquid substances therein.

[0076] 4. Compression treatment

[00...

Embodiment 3

[0087] 1. Raw material preparation

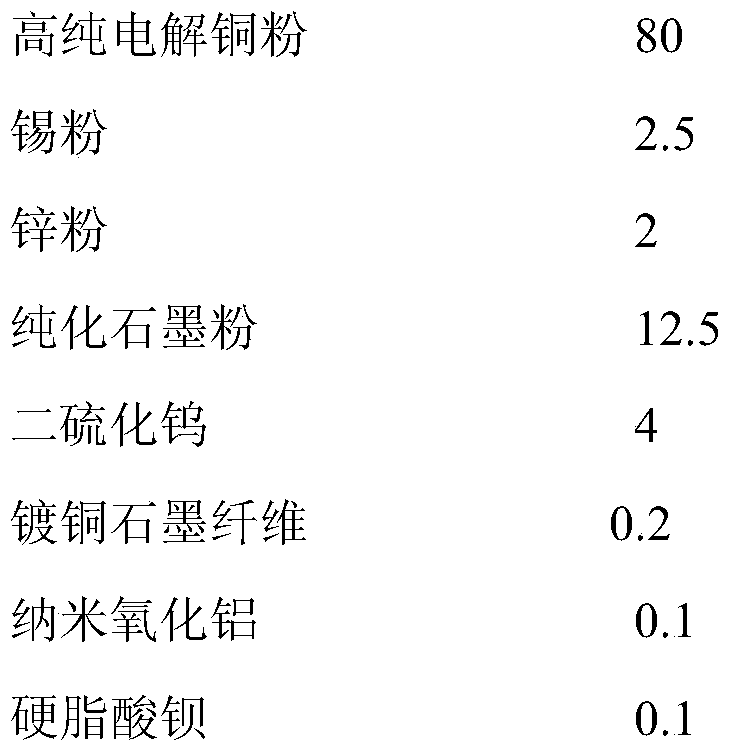

[0088] Raw materials are prepared according to the following proportions by weight:

[0089]

[0090] 2. Prepare the premix

[0091] At room temperature, add the prepared high-purity electrolytic copper powder, tin powder, zinc powder, purified graphite powder, molybdenum disulfide and copper-coated graphite fiber into the V-type mixer, and mix for 40 minutes with the cover closed to obtain the first pre-prepared mix;

[0092] Then spray the nano-alumina alcohol solution (25% by mass fraction) into the mixed first mixture, close the lid and mix for 80 minutes to obtain the second premix;

[0093] Finally, the zinc stearate was added to the mixed second mixture, and the lid was closed and mixed for 40 minutes to prepare the premix.

[0094] 3. Drying treatment

[0095] The premix was placed in a vacuum drying oven, and dried at 20° C. for 3 h to remove the liquid substances therein.

[0096] 4. Compression treatment

[0097] The dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com