Novel food flour mill

A technology for mills and ingredients, applied in the direction of grain processing, etc., can solve the problems of loss of nutrients, original taste, discoloration and taste, poor permeability, etc., to overcome particle congestion and blockage, maintain integrity, and reduce resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

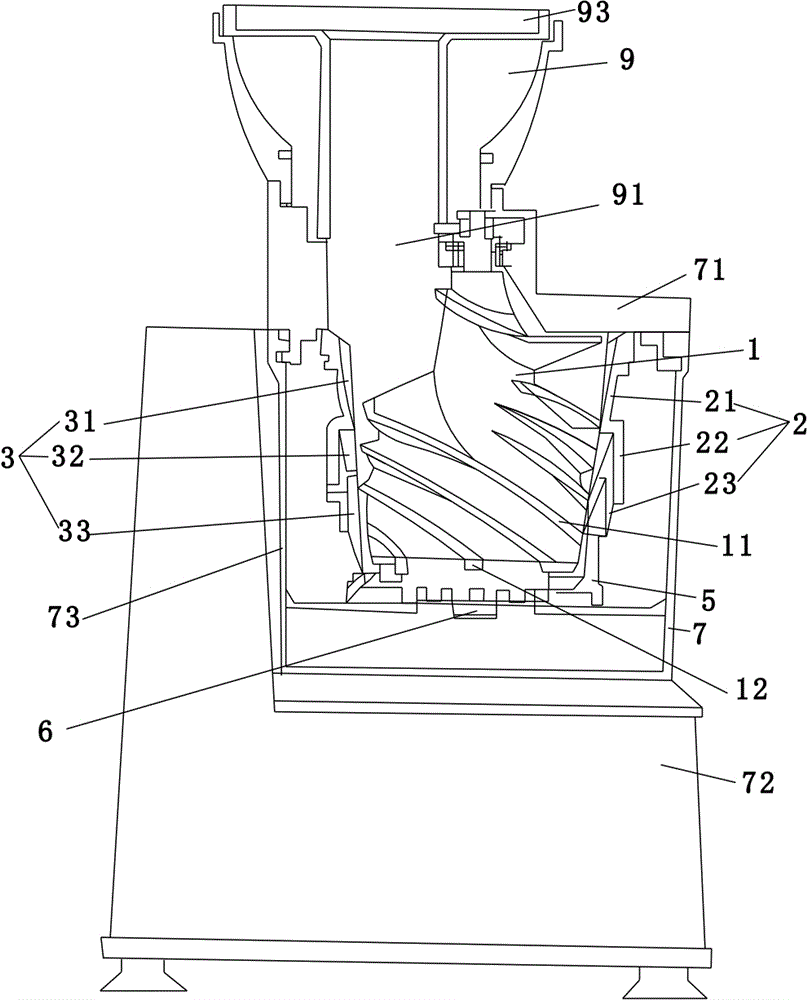

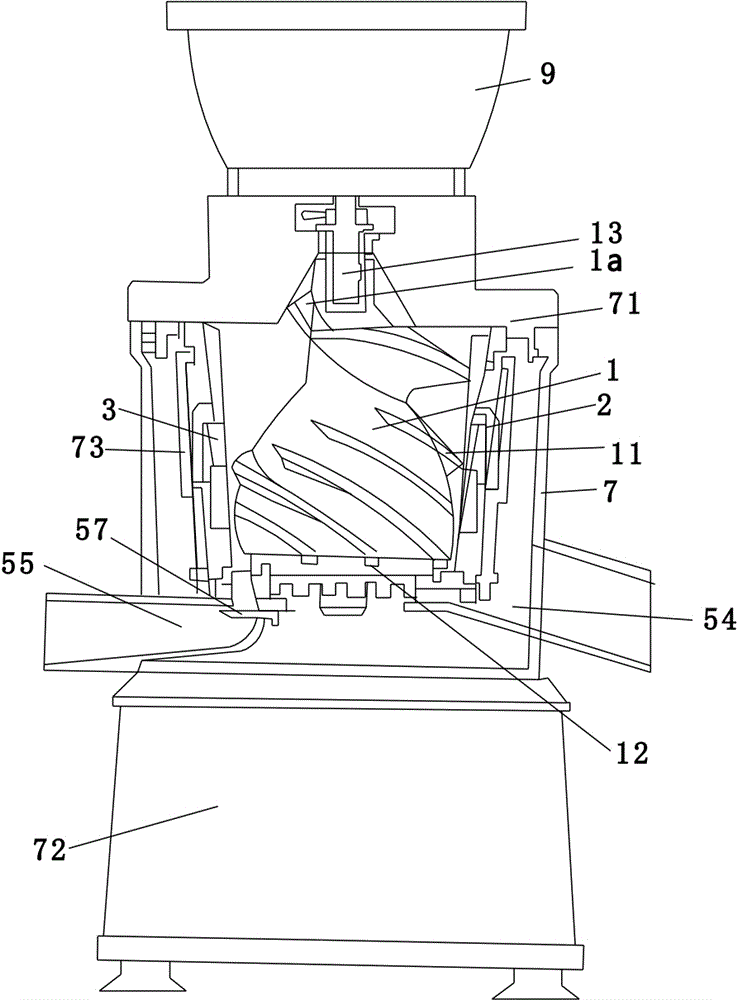

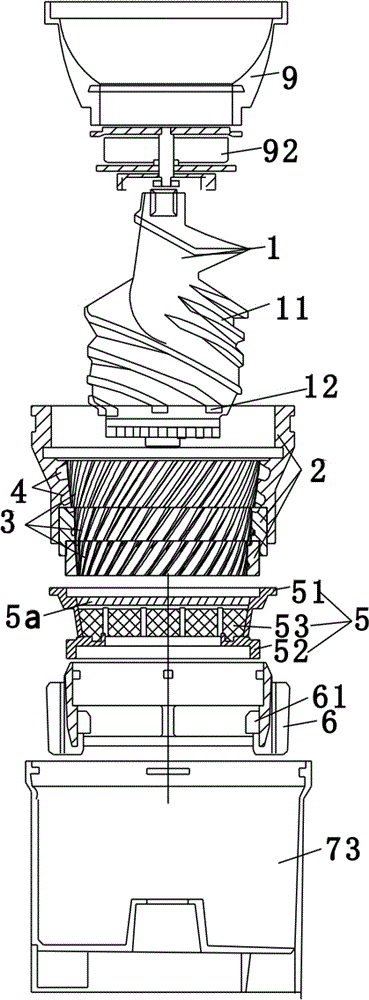

[0035] see Figure 1-6 , including a feeding mechanism, a milling mechanism, a driving mechanism, a discharging mechanism, and a casing 7.

[0036] The feeding mechanism includes a hopper 9, and the hopper 9 is provided with a feeding channel 91. For ease of use, a feeding structure for intermittent feeding is provided in the hopper 9 . Feeding structure In this embodiment, the rotating impeller 92 is taken as an example, of course, it can also be a push plate, a baffle, etc. The blades of the rotating impeller 92 rotate to drive food materials into the feeding channel 91 .

[0037] The milling mechanism includes a spinning cone-shaped screw 1 that vertically rotates and squeezes food materials and runs downward, and a grinding disc 2 that is sheathed outside the screw 1 and cooperates with the screw 1 to be stationary. The grinding disc 2 is provided with at least one layer of cutter rings. The cutter rings include several strip-shaped cutting knives 3 intersecting with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com