Formula for reducing high pressure exponent of solid propellant

A solid propellant, high-pressure technology, applied in the direction of ammonium perchlorate composition, etc., can solve the problems such as the negative impact of propellant performance, and achieve the effects of low smoke signal characteristics, scientific proportioning, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

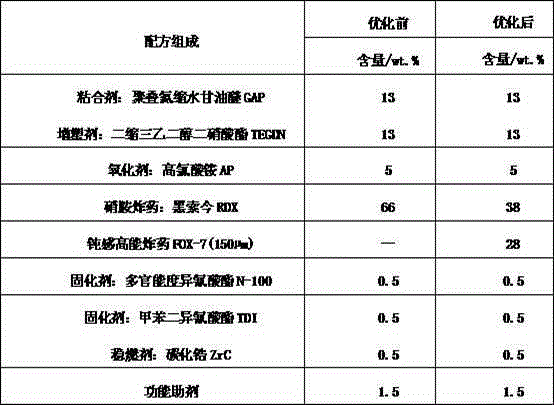

Embodiment 1

[0014] ⑴ Propellant composition (mass percentage)

[0015]

[0016] (2) Propellant performance: Before formula optimization, the pressure index of propellant 11MPa~19MPa is 0.64, after formula optimization, the pressure index of propellant 11MPa~19MPa is 0.46.

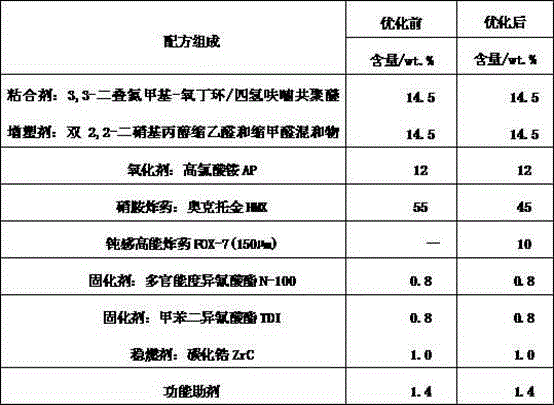

Embodiment 2

[0018] ⑴ Propellant composition (mass percentage)

[0019]

[0020] (2) Propellant performance: Before formula optimization, the pressure index of propellant 11MPa~19MPa is 0.62, after formula optimization, the pressure index of propellant 11MPa~19MPa is 0.45.

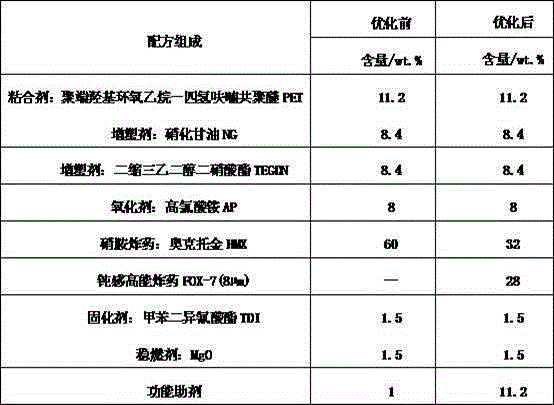

Embodiment 3

[0022] ⑴ Propellant composition (mass percentage)

[0023]

[0024] (2) Propellant performance: Before formula optimization, the pressure index of propellant 11MPa~19MPa is 0.61, after formula optimization, the pressure index of propellant 11MPa~19MPa is 0.48.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com