Sodium tetradecyl sulfate crystal form and preparation method, application and pharmaceutical composition containing sodium tetradecyl sulfate crystal form

A technology of sodium tetradecyl sulfate and composition, applied in the field of medicinal chemistry, achieves the effects of good reproducibility, easy industrialization, and high HPLC purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of Sodium Tetradecyl Sulfate Crystal Form:

[0040] Add 20g of sodium tetradecyl sulfate into 180g of purified water, stir and dissolve at room temperature, filter under reduced pressure with a 0.45μm microporous membrane, pour the filtrate into a stainless steel freeze-drying tray, the height of the solution in the freeze-drying tray should not exceed 12cm, and then put Freeze-dry in a freeze-drying oven at -30°C for 38 hours to obtain the crystal form of sodium tetradecyl sulfate.

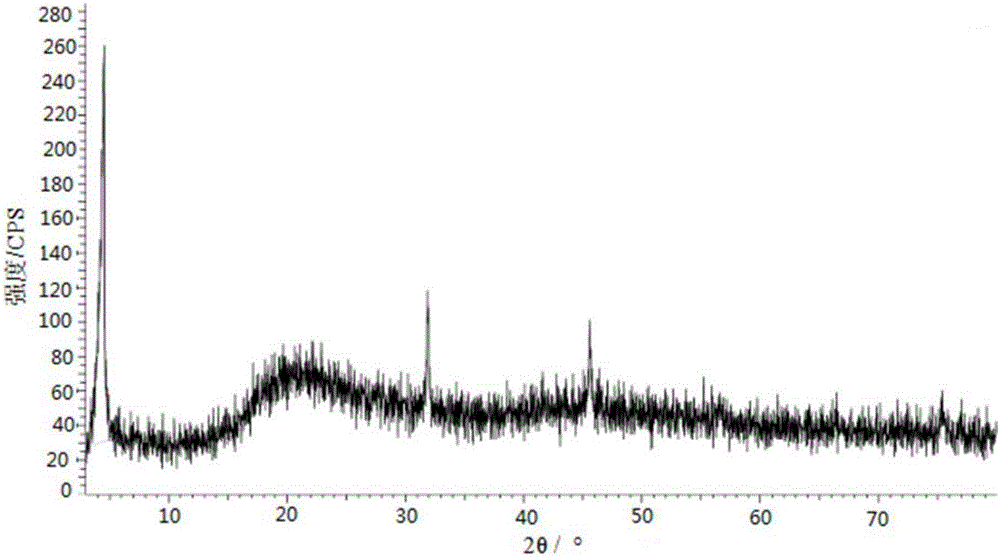

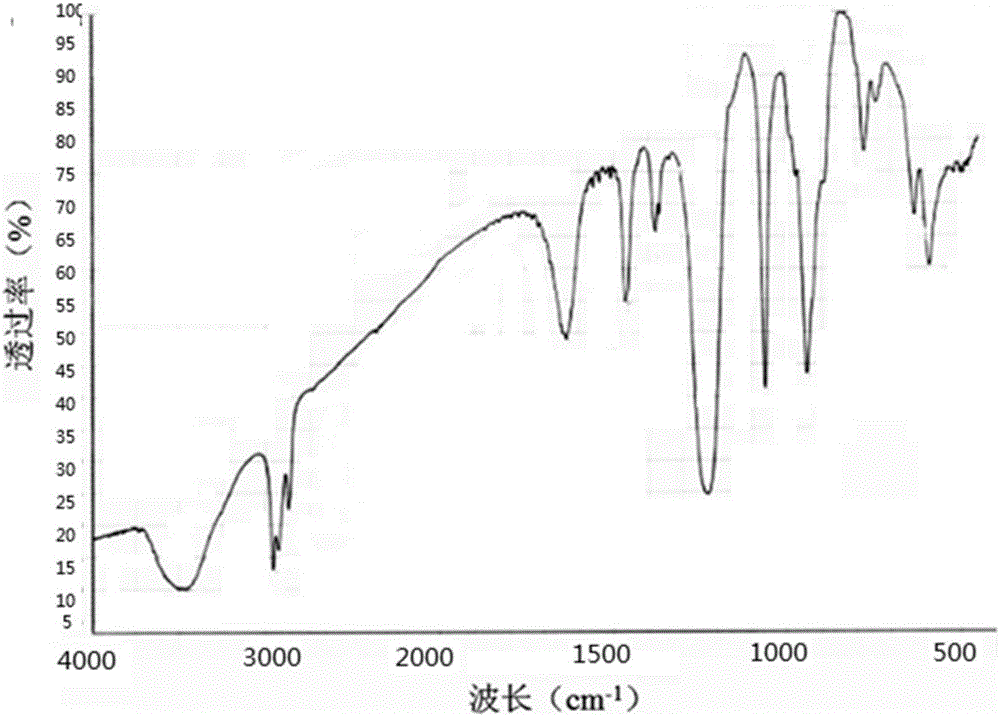

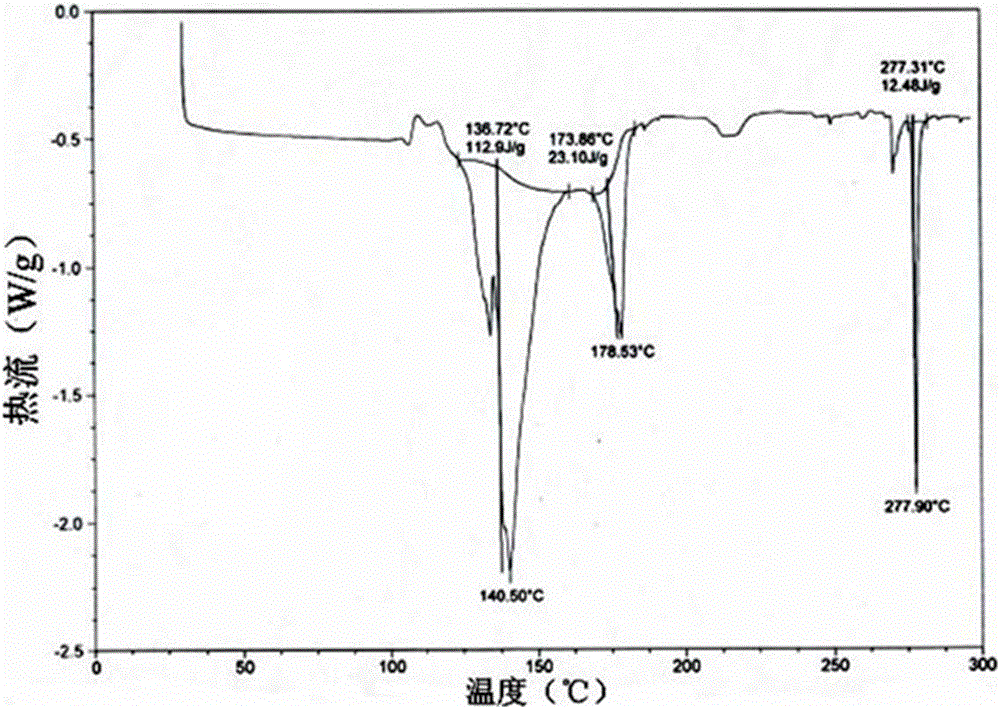

[0041] The X-ray powder diffraction pattern, infrared spectrogram and differential scanning pattern of this crystal form are as follows: figure 1 , figure 2 and image 3 shown.

Embodiment 2

[0043] Preparation of Sodium Tetradecyl Sulfate Crystal Form:

[0044] Add 20g of sodium tetradecyl sulfate into 180g of purified water, stir at room temperature to dissolve, then add 10g of ethanol and stir evenly, filter under reduced pressure with a 0.45μ microporous filter membrane, pour the filtrate into a stainless steel freeze-drying tray, the solution height in the freeze-drying tray is It should not exceed 12 cm, and then freeze-dried in a freeze-drying oven at -5°C for 37 hours to obtain the crystal form of sodium tetradecyl sulfate.

[0045] The X-ray powder diffraction pattern, infrared spectrogram and differential scanning pattern of this crystal form are as follows: figure 1 , figure 2 and image 3 shown.

Embodiment 3

[0047] Preparation of Sodium Tetradecyl Sulfate Crystal Form:

[0048] Add 20g of sodium tetradecyl sulfate into 180g of purified water, stir at room temperature to dissolve, then add 20g of ethanol and stir evenly, filter under reduced pressure with a 0.45μ microporous filter membrane, pour the filtrate into a stainless steel freeze-drying tray, the solution height in the freeze-drying tray is It should not exceed 12 cm, and then freeze-dried in a freeze-drying oven at -10°C for 36 hours to obtain the crystal form of sodium tetradecyl sulfate.

[0049] The X-ray powder diffraction pattern, infrared spectrogram and differential scanning pattern of this crystal form are as follows: figure 1 , figure 2 and image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com