Preparation method for surface hydrophobic and oleophobic film of bronze drum

A hydrophobic, oleophobic, and copper drum technology, which is applied in the field of preparation of surface hydrophobic and oleophobic films, can solve the problems of harsh process conditions and no description of the long-term stability of metal copper films, and achieve the effects of simple preparation methods, broad practical value, and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

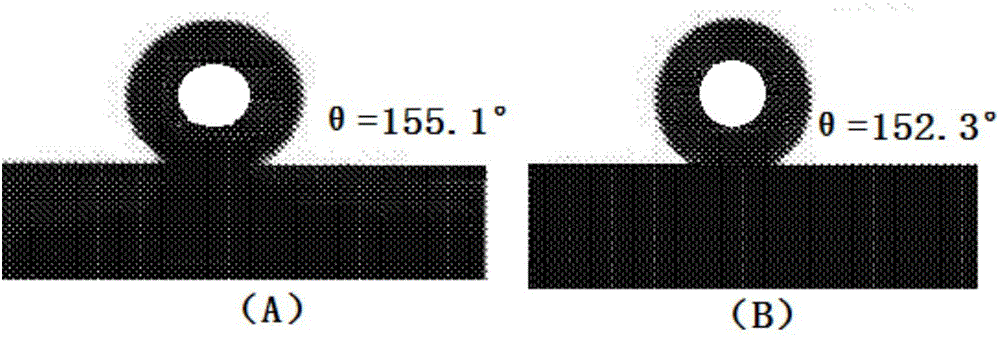

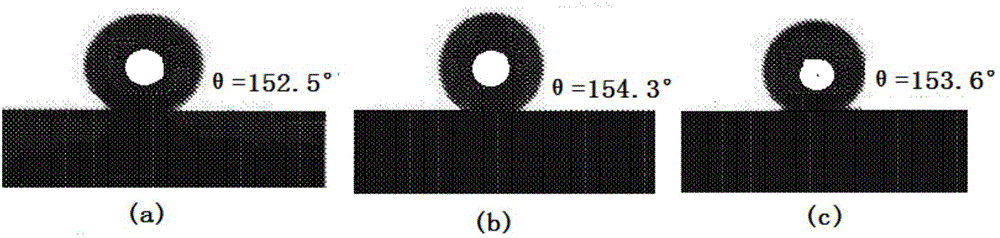

Image

Examples

Embodiment 1

[0032] The preparation method of the surface hydrophobic and oleophobic film of a kind of copper drum of the present invention, comprises the following steps:

[0033] (1) Clean the newly cast copper drum with polysorbate solution to remove the grease and pollutants covered on the surface, and then repeatedly reapply the surface of the copper drum with clean water;

[0034] (2) Immerse the blown and washed copper drum in an ethanol solution with a mass fraction of 20% polyhydric alcohol, and use an ultrasonic device with a wave frequency of 50Kz to carry out ultrasonic treatment on the copper drum for 4h;

[0035] (3) Prepare a perfluorinated fatty acid organic solution with a concentration of 0.01mol / L, and the organic solvent of the perfluorinated fatty acid used is ethanol; ethanol can dissolve the perfluorinated fatty acid very easily. The formula of the perfluoro fatty acid used is CF3(CF2)nCOOH, where n=13.

[0036] (4) Soak the copper drum processed by step (2) into th...

Embodiment 2

[0040] The preparation method of the surface hydrophobic and oleophobic film of a kind of copper drum of the present invention, comprises the following steps:

[0041] (1) Clean the newly cast copper drum with F127 surfactant solution to remove the grease and pollutants covered on the surface, and then repeatedly resurface the copper drum with clean water;

[0042] (2) Immerse the blown and washed copper drum in an ethanol solution with a mass fraction of 30% polyhydric alcohol, and use an ultrasonic device with a wave frequency of 100Kz to carry out ultrasonic treatment on the copper drum for 6h;

[0043] (3) Prepare a perfluorinated fatty acid organic solution with a concentration of 0.04mol / L. The organic solvent of the perfluorinated fatty acid used is isopropanol; isopropanol can dissolve the perfluorinated fatty acid very easily. The formula of the perfluoro fatty acid used is CF3(CF2)nCOOH, where n=16.

[0044] (4) Soak the copper drum processed by step (2) into the pe...

Embodiment 3

[0048] The preparation method of the surface hydrophobic and oleophobic film of a kind of copper drum of the present invention, comprises the following steps:

[0049] (1) Clean the newly cast copper drum with sodium dodecylbenzene sulfonate solution to remove the grease and pollutants covered on the surface, and then repeatedly reapply the surface of the copper drum with clean water;

[0050] (2) Immerse the blown and washed copper drum in an ethanol solution with a mass fraction of 25% polyhydric alcohol, and use an ultrasonic device with a wave frequency of 100Kz to carry out ultrasonic treatment on the copper drum for 5 hours;

[0051] (3) Prepare a perfluorinated fatty acid organic solution with a concentration of 0.03mol / L, and the organic solvent of the perfluorinated fatty acid used is ether; ether can dissolve the perfluorinated fatty acid very easily. The formula of the perfluoro fatty acid used is CF3(CF2)nCOOH, where n=15.

[0052] (4) Soak the copper drum process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com