Manufacturing method of superconducting magnet for high-temperature superconducting maglev train

A technology for maglev trains and superconducting magnets, applied in superconducting magnets/coils, magnetic core manufacturing, magnetic objects, etc., can solve the problems of levitation force and guiding force to be improved, low critical current density, etc., and achieve high critical current density , Increased critical current density and high pinning density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

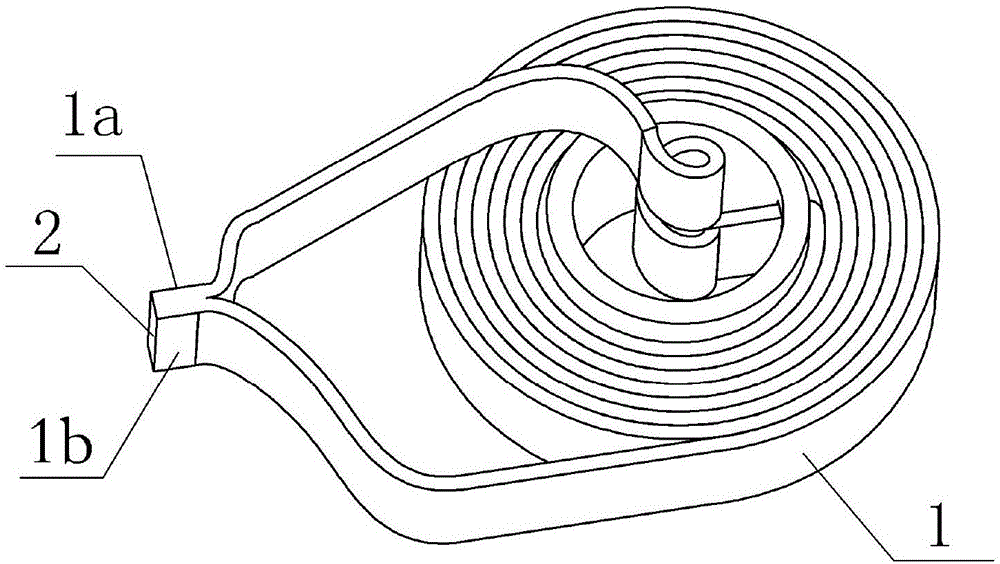

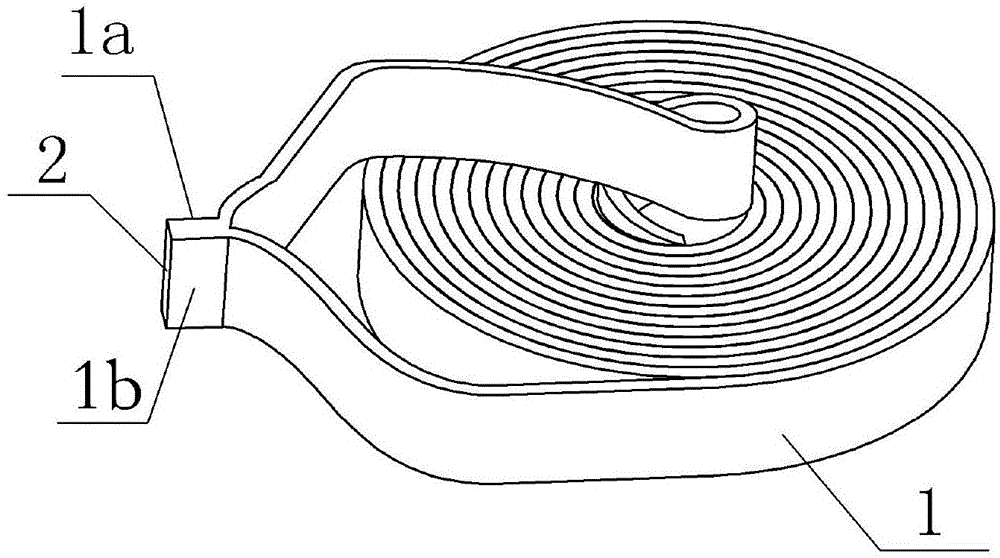

[0026] figure 1 It is shown that the first specific embodiment of the present invention is a method for manufacturing a superconducting magnet for a high-temperature superconducting magnetic levitation train, which is as follows:

[0027] A. Coat the surface of the high-temperature superconducting tape 1 with a curing agent; while coating, wind the high-temperature superconducting tape 1 from the inside to the outside to form a hollow ring or solid round cake, and the tape 1 The inner end 1a is exposed;

[0028] B. Connect the inner end 1a of the high-temperature superconducting tape 1 and the outer end 1b of the high-temperature superconducting tape 1 into a superconducting joint 2 to form a closed superconducting ring, which is obtained.

[0029] The specific method of connecting the inner end 1a of the high-temperature superconducting tape 1 and the outer end 1b of the high-temperature superconducting tape 1 into a superconducting joint 2 is as follows:

[0030] B1. Peel off the pr...

Embodiment 2

[0035] figure 1 Shows that a method for manufacturing superconducting magnets for high-temperature superconducting maglev trains is as follows:

[0036] A. Coat the surface of the high-temperature superconducting tape 1 with a curing agent; while coating, wind the high-temperature superconducting tape 1 from the inside to the outside to form a hollow ring or solid round cake, and put the tape 1 The inner end 1a is exposed;

[0037] B. Connect the inner end 1a of the high-temperature superconducting tape 1 and the outer end 1b of the high-temperature superconducting tape 1 into a superconducting joint 2 to form a closed superconducting cake.

[0038] Among them, the specific method of connecting the inner end 1a of the high-temperature superconducting tape 1 and the outer end 1b of the high-temperature superconducting tape 1 into a superconducting joint 2 is as follows:

[0039] B1. Peel off the protective layer: immerse the inner end 1a and outer end 1b of the high-temperature superco...

Embodiment 3

[0044] A method for manufacturing superconducting magnets for high-temperature superconducting magnetic levitation trains is as follows:

[0045] A. Coat the surface of the high-temperature superconducting tape 1 with a curing agent; while coating, wind the high-temperature superconducting tape 1 from the inside to the outside to form a hollow ring or solid round cake, and put the tape 1 The inner end 1a is exposed;

[0046] B. Connect the inner end 1a of the high-temperature superconducting tape 1 and the outer end 1b of the high-temperature superconducting tape 1 into a superconducting joint 2 to form a closed superconducting ring, which is obtained.

[0047] The specific method of connecting the inner end 1a of the high-temperature superconducting tape 1 and the outer end 1b of the high-temperature superconducting tape 1 into a superconducting joint 2 is as follows:

[0048] B1. Peel off the protective layer: immerse the inner end 1a and outer end 1b of the high-temperature superco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com