Large-pore-size mesoporous carbon/silicon dioxide loaded gold nano-catalyst and synthesis method thereof

A technology of silica and synthesis methods, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of easy loss of metal particles, long time-consuming, cumbersome process and other problems, to achieve the effects of easy large-scale production, considerable economic benefits, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

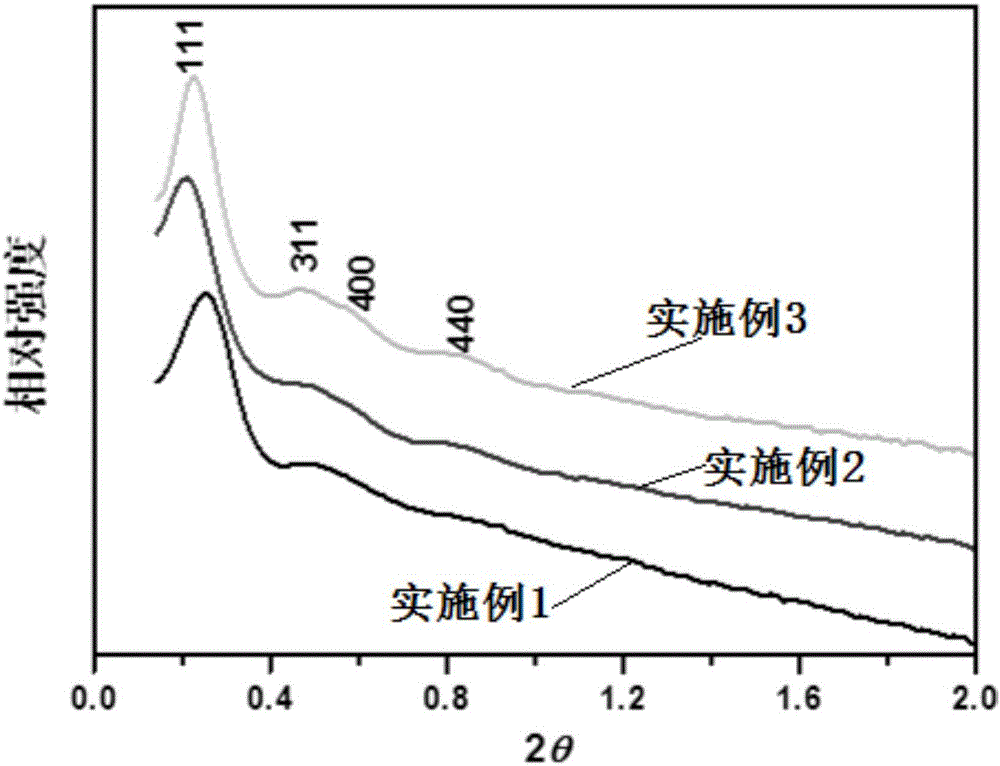

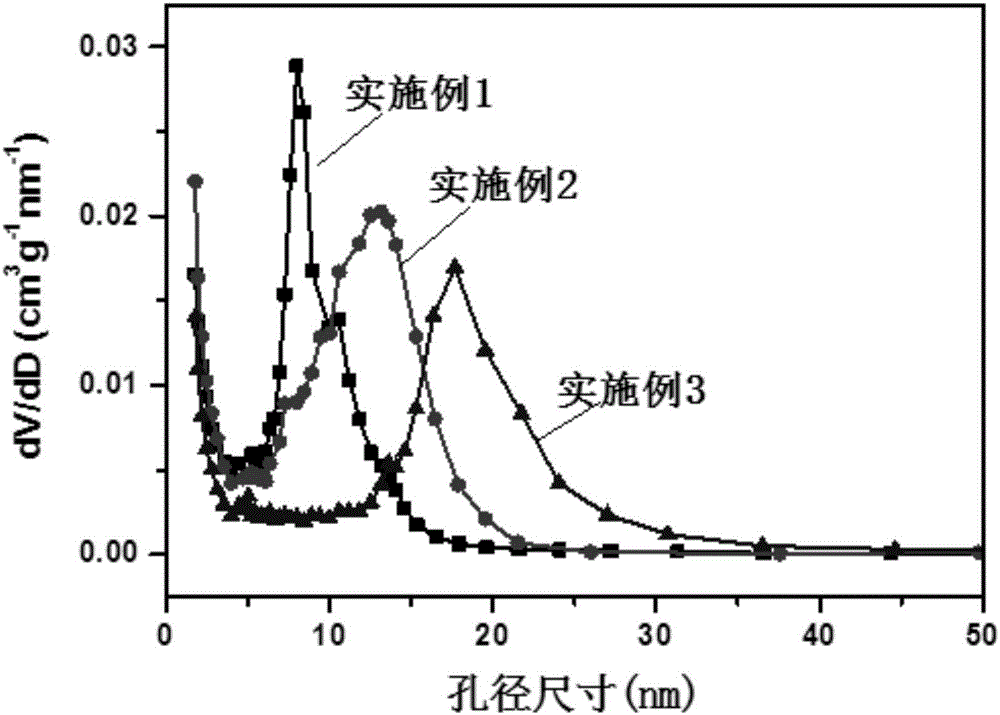

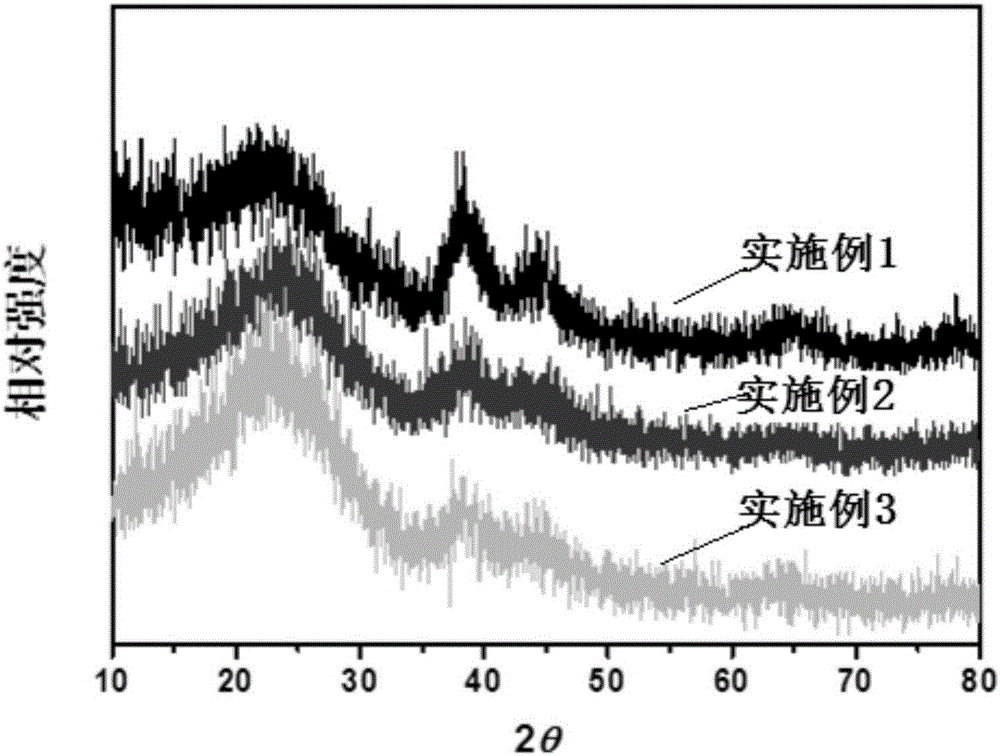

[0041] At 30°C, 4.0 g PS a -PEO b (0.13mmol) was dissolved in 20.00g tetrahydrofuran, stirred for 0.5 hours, added 1mL chloroauric acid solution (0.024mmol); 1.2mmol organic silicon source vinyltrimethoxysilane and 10.8mmol inorganic silicon source TEOS in 1.2g (0.2mol) / L) hydrochloric acid for 30 minutes; mix the two solutions, add 10 g of soluble resole phenolic resin (20 wt %), and stir at 40° C. for 2 hours. The mixed solution was then spread evenly in a petri dish and placed at room temperature for 7 hours to volatilize the organic solvent; finally, it was transferred to a 100°C oven, and after 24 hours, the product was calcined in a nitrogen atmosphere to remove the surfactant.

[0042] The obtained material has a face-centered cubic structure with a pore diameter of 7 nm and a pore volume of 0.38 cm 3 / g, the specific surface area is 325m 2 / g, the gold content is 0.5%, and the gold nanometer size is 5 nm, marked as 0.5Au-SC-7.

[0043] Its X-ray small angle scatte...

Embodiment 2

[0045] At 30°C, 2.0g PS a -PEO b (0.13mmol) was dissolved in 10.00g tetrahydrofuran, stirred for 0.5 hours, added 2mL chloroauric acid solution (0.048mmol); 1.2mmol organic silicon source vinyltrimethoxysilane and 10.8mmol inorganic silicon source TEOS in 1.2g (0.2mol) / L) hydrochloric acid for 30 minutes; mix the two solutions, add 10 g of soluble resole phenolic resin (20 wt %), and stir at 40° C. for 2 hours. The mixed solution was then spread evenly in a petri dish and left at room temperature for 7 hours to volatilize the organic solvent; finally, it was transferred to a 100°C oven, and after 24 hours, the solid was calcined in a nitrogen atmosphere to remove the surfactant.

[0046] The obtained material has a face-centered cubic structure with a pore size of 12 nm and a pore volume of 0.24 cm. 3 / g, the specific surface area is 347m 2 / g, the gold content is 1%, the gold nanometer size is 4 nm, and it is marked as 1Au-SC-12.

[0047] Its characteristic X-ray small a...

Embodiment 3

[0049] At 30°C, 4.0 g PS a -PEO b (0.13mmol) was dissolved in 20.00g tetrahydrofuran, stirred for 0.5 hours, added 5ml chloroauric acid solution (0.072mmol); 1.2mmol organic silicon source vinyltrimethoxysilane and 10.8mmol inorganic silicon source TEOS in 1.2g (0.2mol) / L) hydrochloric acid for 30 minutes; mix the two solutions, add 10.0 g of soluble resole phenolic resin (20 wt %), and stir at 40° C. for 2 hours. The mixed solution was then spread evenly in a petri dish and placed at room temperature for 7 hours to volatilize the organic solvent; finally, it was transferred to a 100°C oven, and after 24 hours, the product was calcined in a nitrogen atmosphere to remove the surfactant.

[0050] The obtained material has a face-centered cubic structure with a pore size of 17 nm and a pore volume of 0.24 cm. 3 / g, the specific surface area is 347m 2 / g, the gold content is 2.5%, and the gold nanometer size is 3 nm, labeled as 2.5Au-SC-17.

[0051] Its characteristic X-ray s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com