Process for producing food-grade carbon dioxide by virtue of resolving gas of decarburization procedure of synthesis ammonia MDEA method

A technology for carbon dioxide and ammonia synthesis, applied in the chemical industry, can solve the problems of aggravating the greenhouse effect, poor product quality, waste of precious carbon dioxide resources, etc., and achieve the effects of simple and reliable process, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

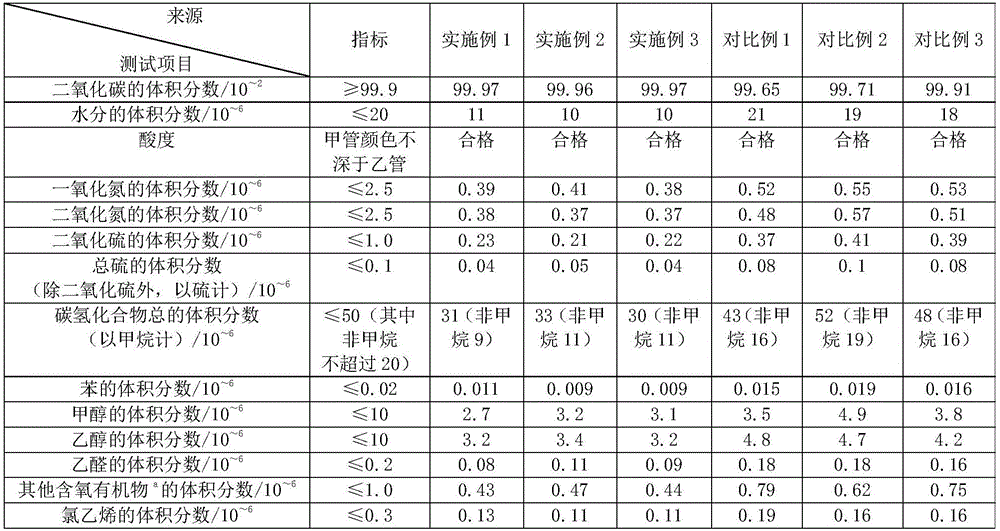

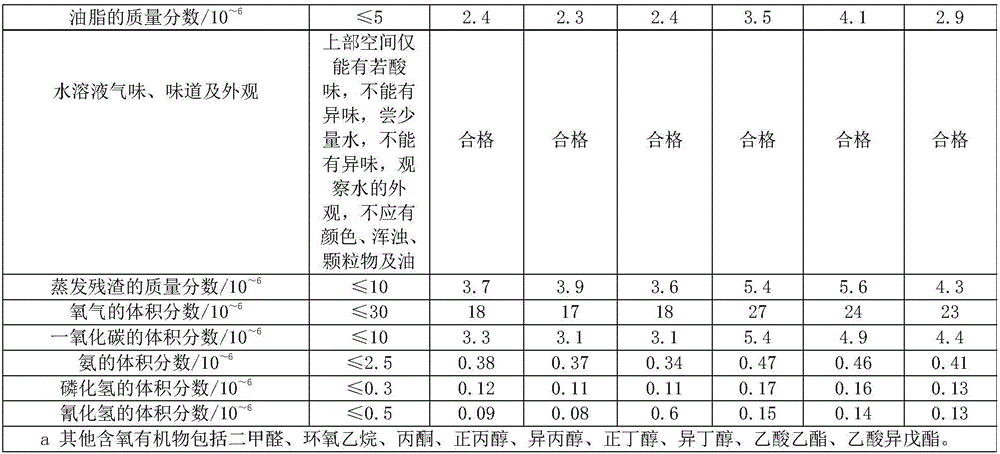

Examples

Embodiment 1

[0026] The process for producing food-grade carbon dioxide from the analytical gas in the MDEA decarburization process of synthetic ammonia comprises the following steps:

[0027] A. Compression process: The analytical gas from the MDEA decarburization process of synthetic ammonia is washed by a water washing tower and then enters a compressor for three-stage compression until the pressure of the gas is 2.2MPa and the temperature is 2 content of ≤30mg / L;

[0028] B. Purification process: the gas cooled by the pre-cooler enters the adsorption tower, and the content of methanol in the gas is adsorbed by activated carbon with a particle size of 3.0 mm and a strength ≥ 90% < 70 ppm;

[0029] C. Drying process: The gas after adsorption treatment then enters the dryer, and the content of methanol is adsorbed to <8ppm under the action of molecular sieves with a particle size of 3mm, compressive strength ≥ 60N / particle, and bulk density ≥ 0.64g / mL. The moisture content is adsorbed to ...

Embodiment 2

[0033] The process for producing food-grade carbon dioxide from the analytical gas in the MDEA decarburization process of synthetic ammonia comprises the following steps:

[0034] A. Compression process: The analytical gas from the MDEA decarburization process of synthetic ammonia is washed by a water washing tower and enters the compressor for three-stage compression until the pressure of the gas is 2.2MPa and the temperature is 2 content of ≤30mg / L;

[0035] B. Purification process: the gas cooled by the pre-cooler enters the adsorption tower, and the methanol content in the gas is adsorbed by activated carbon with a particle size of 3.5mm and a strength ≥ 90% < 70ppm;

[0036] C. Drying process: The gas after adsorption treatment then enters the dryer, and the content of methanol is adsorbed to <8ppm under the action of molecular sieves with a particle size of 5mm, compressive strength ≥ 60N / particle, and bulk density ≥ 0.64g / mL. The moisture content is adsorbed to <15ppm, ...

Embodiment 3

[0040] The process for producing food-grade carbon dioxide from the analytical gas in the MDEA decarburization process of synthetic ammonia comprises the following steps:

[0041] A. Compression process: The analytical gas from the MDEA decarburization process of synthetic ammonia is washed by a water washing tower and then enters a compressor for three-stage compression until the pressure of the gas is 2.2MPa and the temperature is 2 content of ≤30mg / L;

[0042] B. Purification process: the gas cooled by the pre-cooler enters the adsorption tower, and the methanol content in the gas is adsorbed by activated carbon with a particle size of 3.2 mm and a strength ≥ 90% < 70 ppm;

[0043] C. Drying process: The gas after adsorption treatment then enters the dryer, and the content of methanol is adsorbed to <8ppm under the action of molecular sieves with a particle size of 3.5mm, a compressive strength ≥ 60N / particle, and a bulk density ≥ 0.64g / mL , the moisture content is adsorbed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com