Membrane treatment method and device

A technology of membrane treatment and adding equipment, which is applied in the field of membrane treatment methods and equipment, and can solve problems such as unstable system operation, clogging, and increased membrane pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

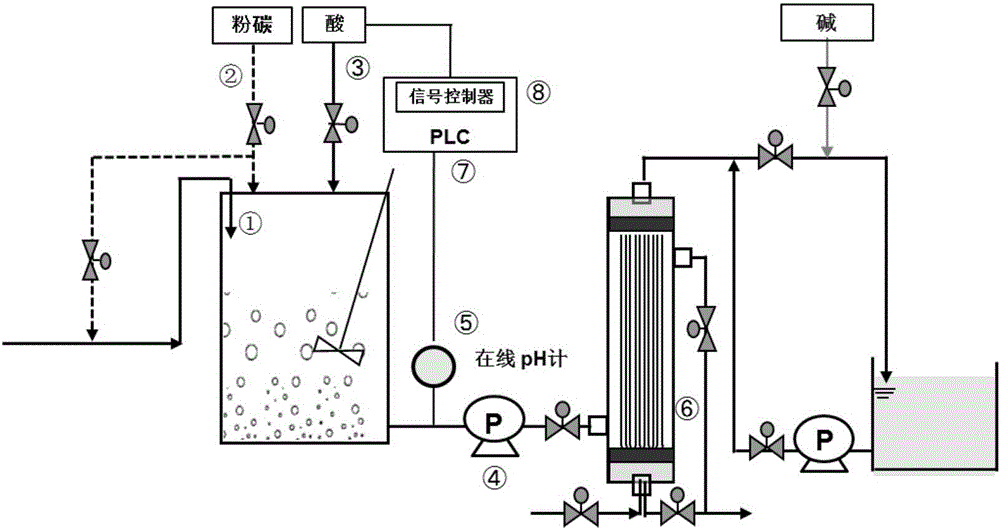

Embodiment 1

[0019] Add 30mg / L powdered activated carbon to a certain raw water. After mixing for 30 minutes, the online pH meter of the water inlet pipeline tested that the pH was 8.1. After the test result was passed through the signal control device, the acid dosing device was started, and the hydrochloric acid was added and the pH was set at 5.5. The pH of the post-membrane inlet water is controlled at 5.5, and it enters the pressurized ultrafiltration membrane device from the raw water pump and the inlet water line for filtration. The membrane filtration flux is 2.5m / d, and the filtration cycle time is 30min. After washing for 1.0min, the membrane runs stably continuously, and the membrane chemical cleaning cycle exceeds 90 days.

Embodiment 2

[0024] Dosing 100mg / L powdered activated carbon into a raw water, after mixing for 60 minutes, the online pH meter of the water inlet pipeline tested that the pH was 7.5. Control at 6.0, enter the submerged ultrafiltration membrane device for filtration through the raw water pump and water inlet pipeline, the membrane filtration flux is 2.0m / d, the filtration cycle time is 30min, and then backwash and air wash for 1.0min respectively after draining, the membrane is continuous The operation is stable, and the chemical cleaning cycle of the membrane exceeds 60 days, which ensures the removal of organic matter and reduces the cleaning frequency of the membrane, prolonging the membrane service life.

Embodiment 3

[0029] A certain raw water enters the raw water tank 1 through the water inlet pipeline, and the powdered activated carbon dosing device 2 above the raw water tank 1 starts to add powdered activated carbon. After adding and staying in the raw water tank for 15 minutes, the online pH meter 5 on the raw water tank and the membrane module inlet pipeline tested 7.0, and the test result entered the signal control device 8 through the PLC control unit 7, and the signal control device 8 started the acid dosing device 3 and Set the pH to 5.5 for hydrochloric acid dosing. After adding hydrochloric acid, the pH of the influent water is controlled at 5.5. The raw water pump 4 enters the submerged ultrafiltration membrane module 6 for filtration. The membrane filtration flux is 1.5m / d, and the filtration cycle time is After draining for 30 minutes, backwashing and air washing for 1.0 minutes respectively, the membrane has been running stably for more than 90 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com