Heat film coupled water feeding allocating system for desalting seawater

A thermal film coupling, seawater technology, applied in heating water/sewage treatment, seawater treatment, water/sewage treatment, etc., can solve problems such as difficulty in operation, reverse osmosis seawater desalination, and inability to operate normally, to improve recovery rate, adjust The effect of large range and high adjustment precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The purpose of the present invention is to provide a cooling method for thermal film coupled seawater desalination concentrated brine, which is used to realize the temperature adjustment of the concentrated brine in the low-temperature multi-effect seawater desalination system, so that it can reach the temperature condition suitable for reverse osmosis for secondary desalination . It is achieved by the scheme described below.

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

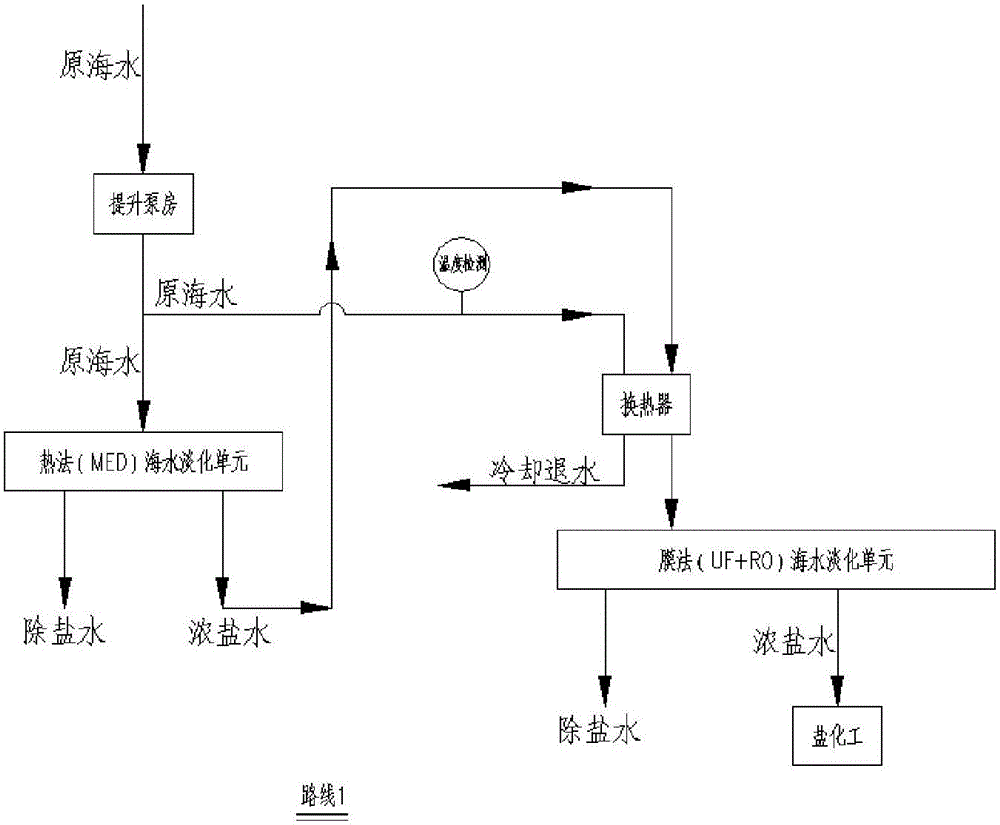

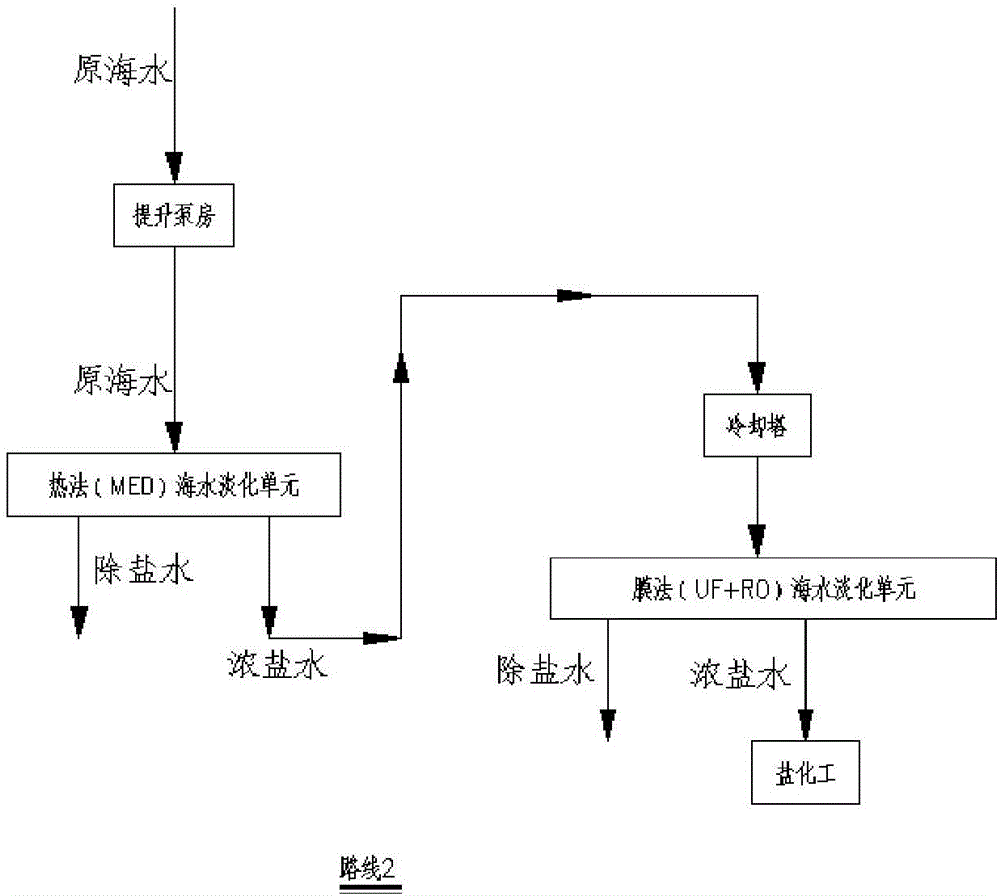

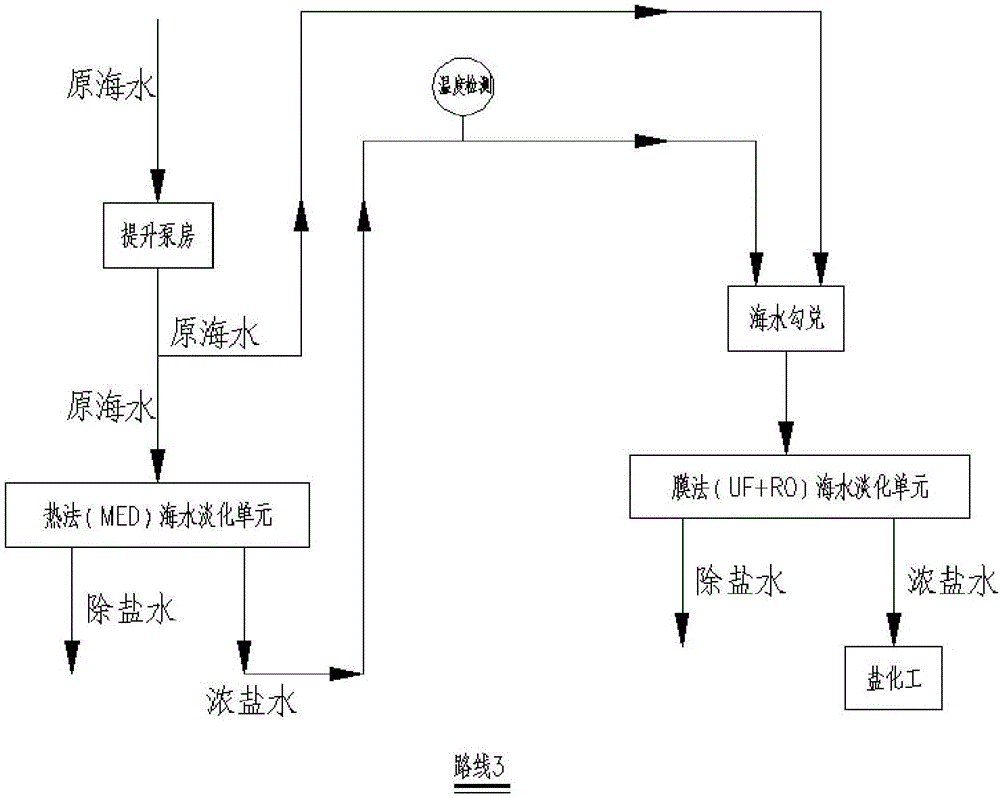

[0036] figure 1 , 2 , 3, and 4 are circuit diagrams of modes 1, 2, 3, and 4 of the seawater desalination system of the present invention, respectively.

[0037] Figure 5 , 6 , 7, and 8 are flow charts of modes 1, 2, 3, and 4 of the seawater desalination system of the present invention, respectively. Modules A, B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com