Drying method and device for steel slag tailings

A drying device and drying method technology, applied in the direction of heating devices, drying solid materials, dry cargo handling, etc., can solve the problems of occupying storage space, production difficulties of enterprises, etc., to reduce floor space, shorten drying time, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

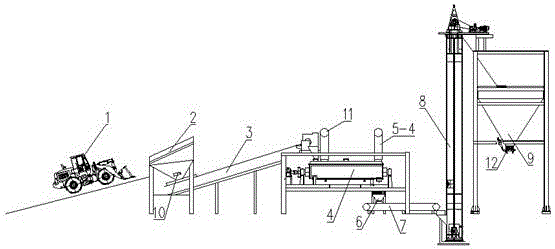

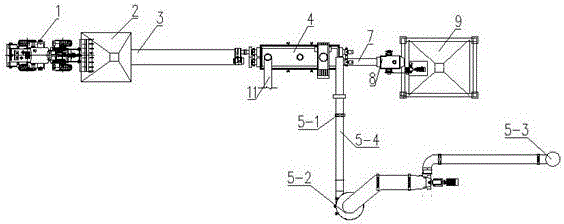

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand more clearly.

[0027] As the drying method of the present invention, waste heat boiler exhaust gas is used to dry the tailings of steel slag after wet treatment, so as to shorten the dehydration time of tailings.

[0028] The method comprises the steps of:

[0029] Unload the steel slag tailings after wet treatment into the tailing slag receiving bin;

[0030] Open the dust removal butterfly valve in the dust removal pipe, so that the dust generated during the tailing heat exchange process is transported to the spray tower through the dust removal pipe, and then discharged through the chimney;

[0031] Transport the tailings in the slag receiving bin to the rotary drum dryer;

[0032] Waste heat boiler exhaust gas and tailings are sent to the drum dryer at the same time;

[0033] Turn the drum dryer so that th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap