Multi-circuit processing monitoring system for hydraulic turbine temperature signals based on network technologies

A technology of temperature signal and network technology, which is applied in the network field, can solve the problems of inability to transmit monitoring information in time and poor accuracy of water turbine temperature monitoring, and achieve the effect of fast transmission of monitoring information, ensuring accuracy, and simple monitoring system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

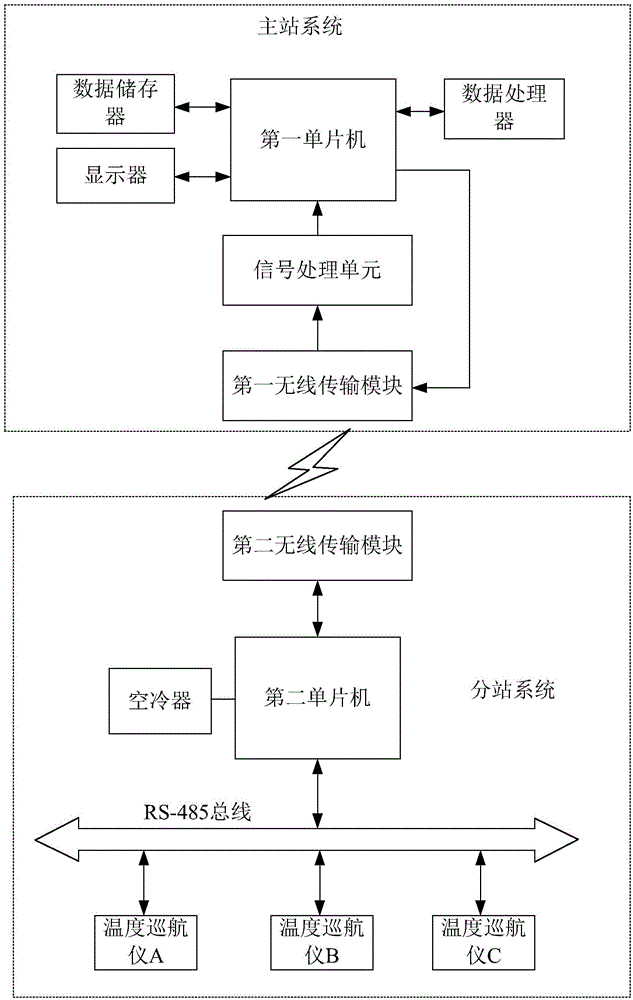

[0024] Such as figure 1 As shown, the present invention is mainly composed of a main station system and a substation system connected with the main station system through a wireless network. The main station system such as figure 1 As shown, it consists of a first single-chip microcomputer, a data storage, a display, a data processor and a signal processing unit all connected to the first single-chip computer, and a first wireless transmission module connected to the signal processing unit. The substation system such as figure 1 As shown, it consists of the second single-chip microcomputer, the second wireless transmission module and the air cooler connected to the second single-chip microcomputer respectively, and the temperature cruiser A, temperature cruiser B and The temperature cruiser C is composed; the first wireless transmission module is connected to the second wireless transmission module through a wireless network; the first single-chip microcomputer is also conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com