Arc sensing seam tracking control method and device based on harmonic analysis

An arc sensing and tracking control technology, applied in arc welding equipment, electrode support devices, manufacturing tools, etc., can solve the problems of difficult detection of welding torch height deviation and inaccurate welding seam deviation detection results, etc., and achieve strong anti-interference ability, The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

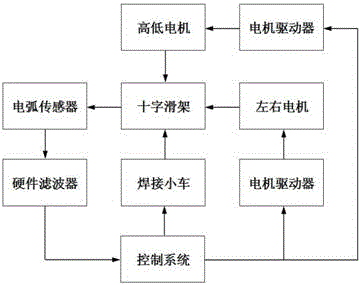

[0034] Embodiment 1: The system block diagram of an arc sensing weld seam tracking control method and device based on harmonic analysis of the present invention is as follows figure 1 As shown, the system includes arc sensor, hardware filter, control system, welding trolley, cross carriage, cross carriage motor, and motor driver; the arc sensor scans the weld bevel and outputs arc sensing signal, and the hardware filter The arc sensing signal is processed by low-pass filtering, and then data sampling and software clipping processing are carried out through the control system. The arc sampling data processed by the software is detected by the double harmonic amplitude characteristic ratio method to detect the left and right deviation of the weld. The space weighted integral difference method is used to detect the height deviation of the weld seam, and the welding position adjustment of the welding torch is completed by controlling the movement of the cross carriage according to ...

Embodiment 2

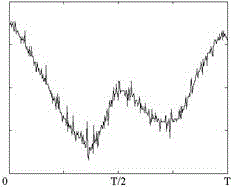

[0062] Embodiment 2: By the method of the present invention, the arc sensor is used to scan the weld bevel during the welding process. When welding under a certain weld deviation, the output signal waveform of the hardware filter is as follows: Figure 9 As shown, there are still a few pulse spikes in the arc signal.

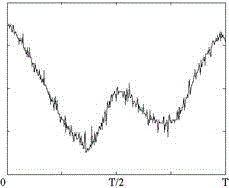

[0063] The output signal of the hardware filter passes through the control system for arc signal sampling and software filtering processing, and the waveform of the arc signal after software processing is as follows: Figure 10 As shown, the pulse spike amplitude is suppressed.

[0064] Discrete Fourier transform is performed on the arc signal processed by the software, and the arc signal is converted into arc signal harmonics, and the harmonic components containing welding seam deviation information are retained and inverse discrete Fourier transform is performed. The obtained arc signal harmonic waveform is as follows: Figure 11 shown.

[0065] Using the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com