Numerical control processing method and device for complex molded surface of rotor blade of air compressor

A compressor rotor and processing method technology, which is applied in the field of mechanical processing of special parts, can solve the problem that complex compressor rotor blade profiles are difficult to achieve precision numerical control machining, and achieve the effects of reducing deformation, improving processing efficiency, and ensuring surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

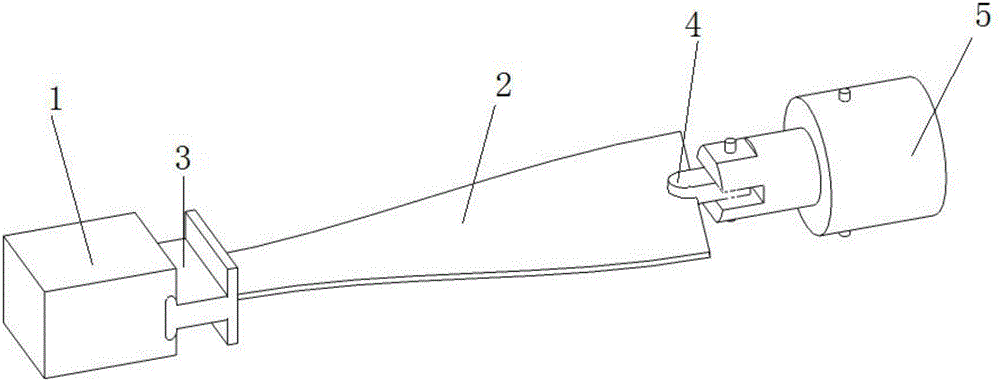

[0020] like figure 1 As shown, it is the clamping method of the rotor blade of the compressor in the present invention, one end is positioned with the chuck 1 to clamp the blade 2 tenon 3, and the other end clamps the blade 2 through the spring chuck 4 connected to the cylinder 5 to assist in tensioning , Trim the edge with a cylindrical milling cutter to remove the margin of the front and rear edges of the blade 2, then spirally mill the blade body with a cylindrical milling cutter, rough and finely mill the edge plate with a ball-end cutter, and finally spirally mill the root of the blade 2 with a ball-end cutter.

[0021] Specifically, the numerical control processing method that the present invention provides is as follows:

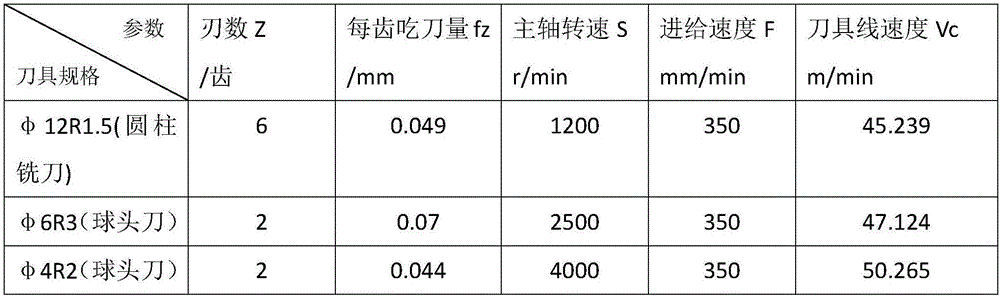

[0022] 1. Determine the tool radius according to the curvature radius of the blade shape. Under the condition that the curvature radius allows, use a cylindrical cutter as much as possible to increase the tool processing step distance and improve proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com