Automobile floor mat having antiskid and damp-proof functions

A technology for car mats and functions, applied in vehicle parts, special positions of vehicles, lamination, etc., can solve problems such as hindering drivers from normal control of accelerator pedals and brake pedals, reducing the service life of mats, and lack of moisture resistance. Achieve the effect of improving user satisfaction, improving utilization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with specific embodiments.

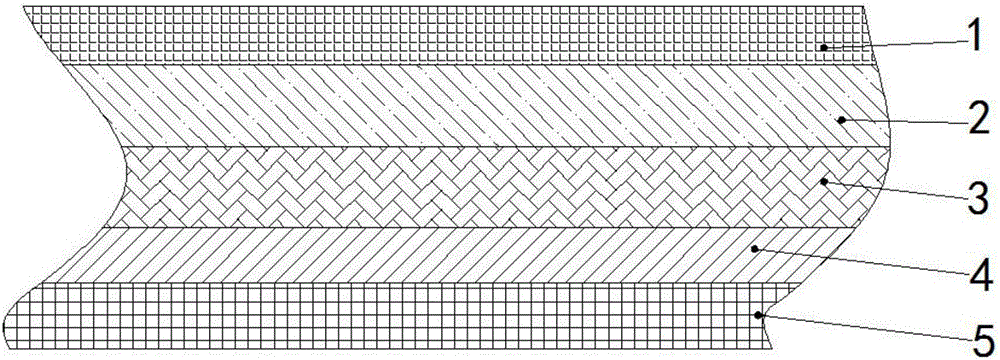

[0014] A car floor mat with anti-slip and moisture-proof function, comprising a microfiber cortex layer 1, a non-woven fleece layer 2, a polyisoprene rubber layer 3, an XPE layer 4 and a silicone rubber anti-slip layer 5 from top to bottom;

[0015] The thickness of the microfiber cortex 1 is 3-5mm, and the superfiber cortex is made of polyurethane, spandex and PU; it has good wear resistance and flexibility, and is impervious to water. The convex and concave patterns are pressed on the fiber skin layer 1 to play the role of anti-slip and moisture-proof;

[0016] The thickness of the non-woven fleece layer 2 is 5-8 mm, and the non-woven layer has the characteristics of air permeability, sound insulation, and non-combustibility, which can improve the performance of the present invention;

[0017] The polyisoprene rubber layer 3 has a thickness of 1 to 3 mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com