Photochromic cloth and preparation method

A photochromic and photochromic technology, applied in the field of textile fabrics, can solve the problems of discoloration performance failure, loss of photochromic compound materials, and shortening of fabric discoloration life. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

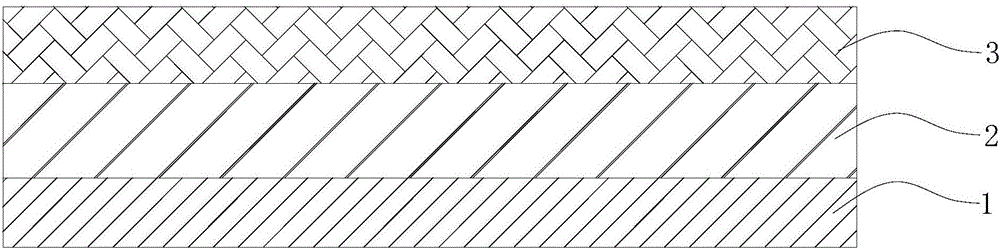

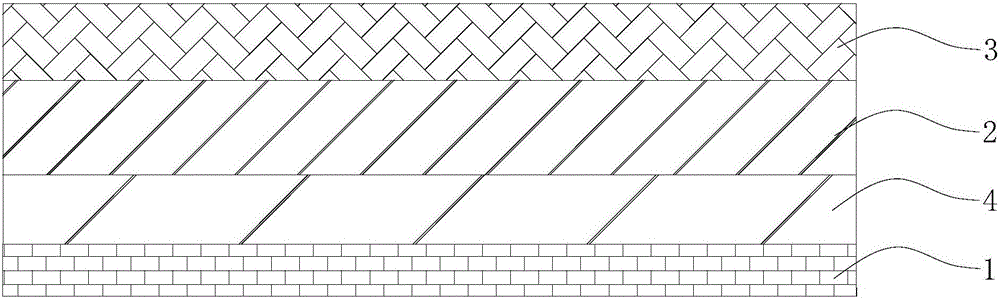

[0049] The preparation method of photochromic cloth of the present invention comprises the following steps:

[0050] 1) Prepare base fabric layer 1 with spandex fiber as raw material;

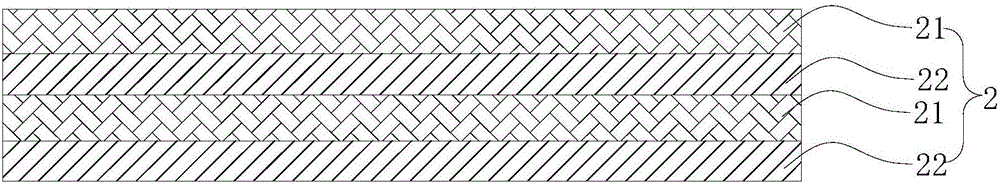

[0051] 2) Melt-spinning the photochromic compound and polyester to prepare the photochromic fiber, using the photochromic fiber as the raw material to prepare the photochromic fiber layer 21;

[0052] 3) Using melamine resin as the wall material and the tetrachlorethylene solution of spirooxazine compounds as the core material, the photochromic microcapsules were prepared by in-situ polymerization, and the photochromic microcapsules were fixed on the adhesive to prepare Obtain the photochromic microcapsule layer 22;

[0053] 4) The photochromic fiber layer 21 prepared in step 2) and the photochromic microcapsule layer 22 prepared in step 3) are alternately stacked to prepare a photochromic layer 2;

[0054] 5) coating the nano silicon dioxide layer 3 on the surface of the photochromic layer 2...

Embodiment 1

[0058] In step 2), the mass ratio of photochromic compound to polyester in the raw materials for photochromic fiber preparation is 1:30.

[0059] In step 3), the preparation process of photochromic microcapsules is that the tetrachlorethylene solution of 0.5% spirooxazine compound is added to the aqueous solution of 0.1% sodium lauryl sulfate by 6ml mass concentration placed in an emulsifier and emulsified for 20 minutes at a speed of 15000rpm to obtain an emulsion; add 30ml of melamine resin prepolymer with a mass concentration of 35% to the prepared emulsion, adjust the pH value to 4 with hydrochloric acid, and then add 50ml of 4.5% polyethylene glycol, heated to 60°C, kept warm for 4 hours, stopped the reaction to obtain photochromic microcapsules; washed with deionized water and dried to obtain photochromic microcapsules.

Embodiment 2

[0061] In step 2), the mass ratio of photochromic compound to polyester in the raw materials for photochromic fiber preparation is 3:40.

[0062] In step 3), the preparation process of the photochromic microcapsules is that 10ml of the mass concentration of 0.8% spirooxazine compound perchlorethylene solution is added to 70ml of the mass concentration of 0.1% sodium lauryl sulfate placed in an emulsifier and emulsified at 20,000rpm for 20min to obtain an emulsion; add 50ml of melamine resin prepolymer with a mass concentration of 50% to the prepared emulsion, adjust the pH value to 5 with hydrochloric acid, and then add 100ml The polyethylene glycol with a mass concentration of 2% is heated to 70° C., kept for 3 hours, and the reaction is stopped to obtain photochromic microcapsules; washed with deionized water and dried to obtain photochromic microcapsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com