Preparation method of luminescence tin halide perovskite colloid nano-crystals

A technology of perovskite and nanocrystals, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of high toxicity of organophosphorus and limited research development, and achieve the effect of simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

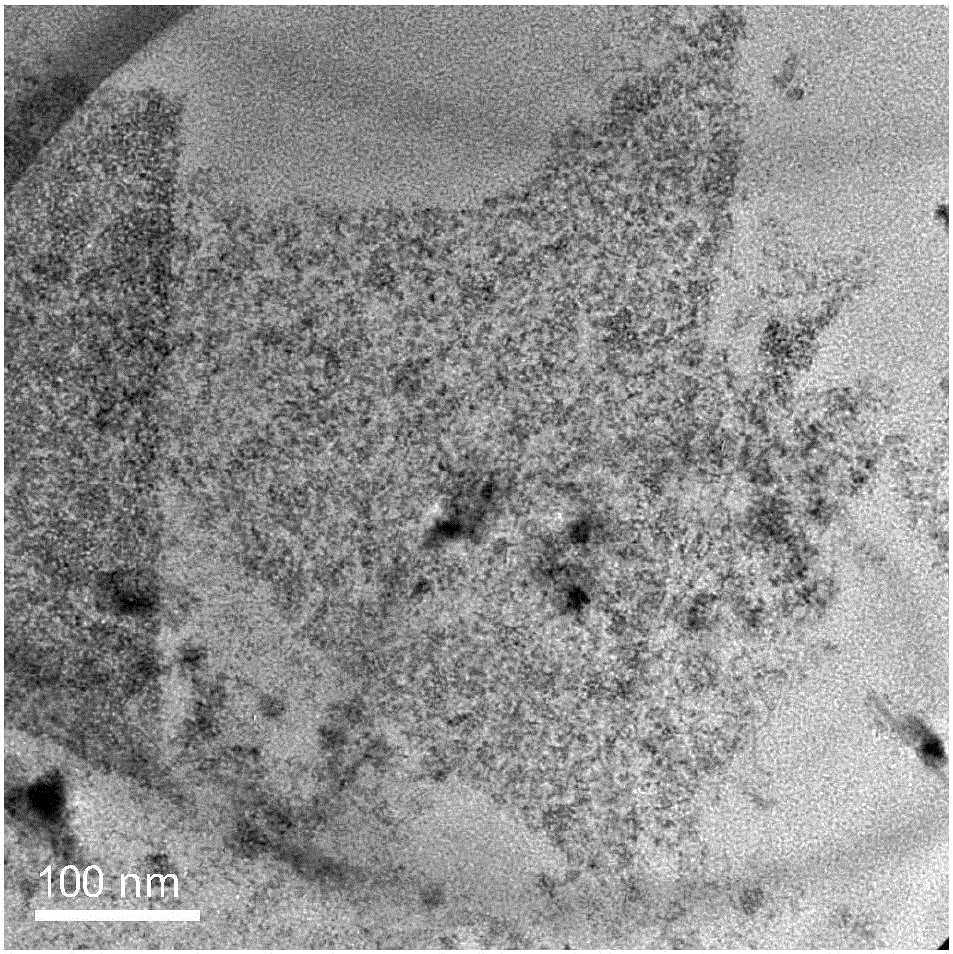

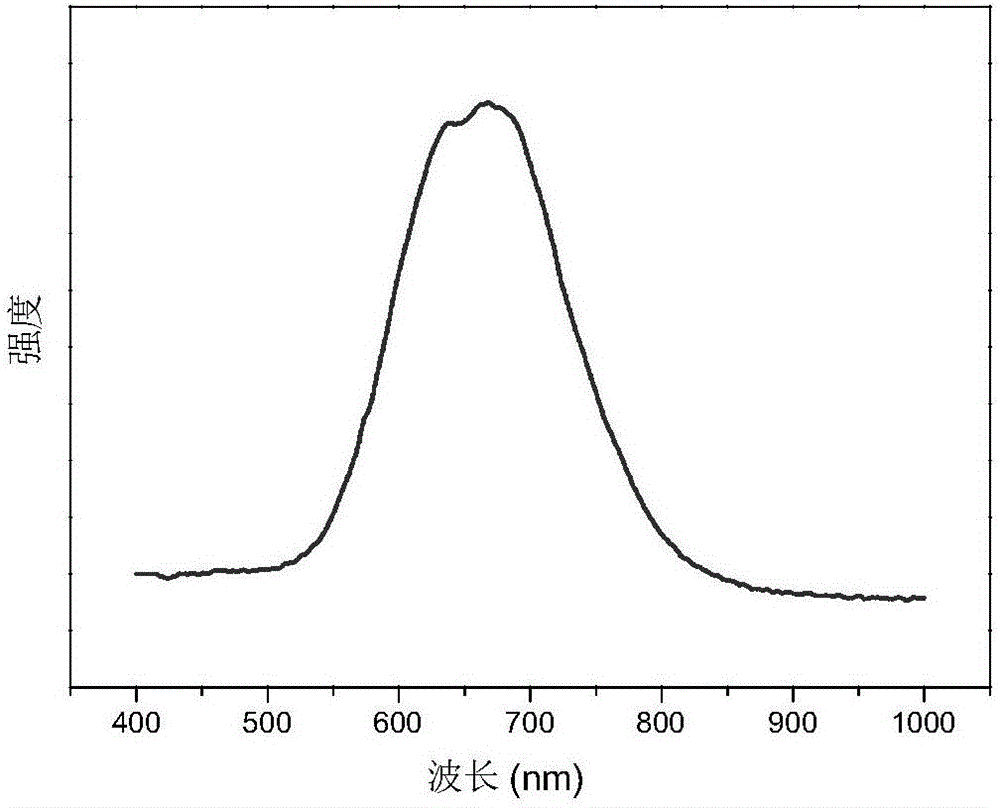

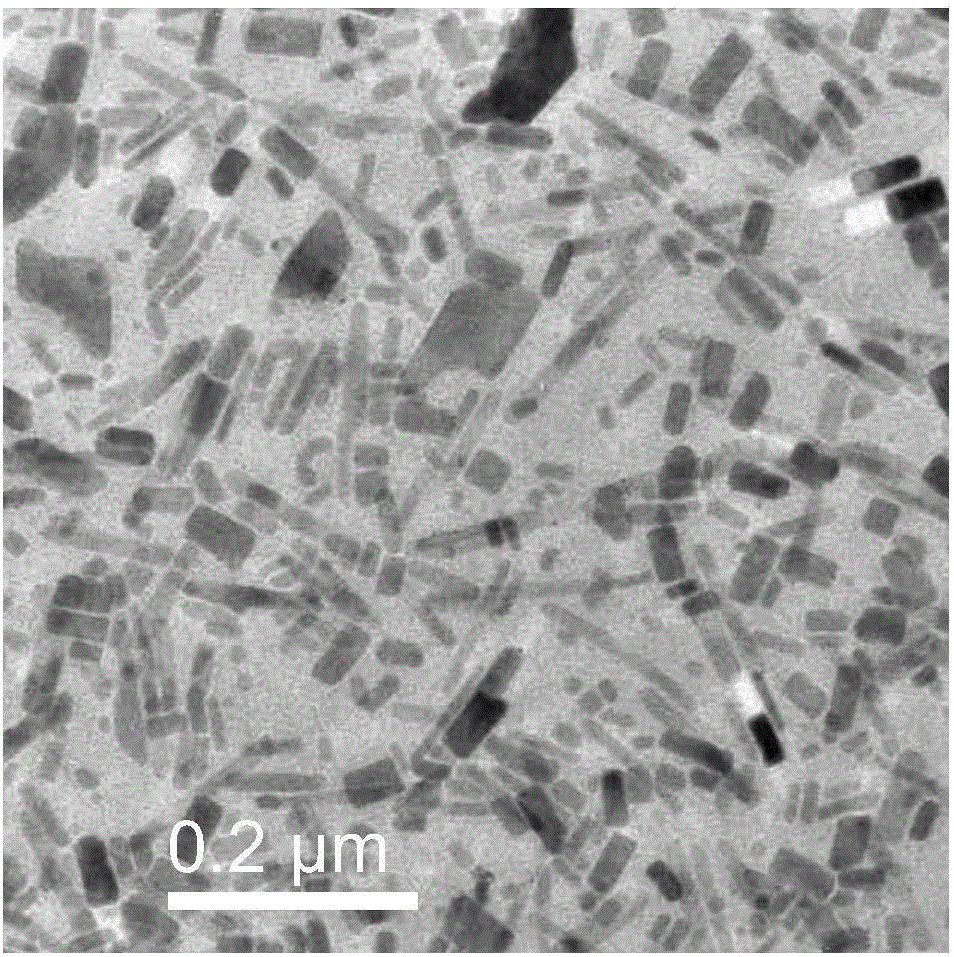

Image

Examples

Embodiment 1

[0036] First prepare the cesium precursor solution cesium oleate: take 0.8mmol (1.3g) of cesium carbonate powder, 4mL of oleic acid and 16mL of octadecene, mix them, remove water and oxygen at 120°C for 30min, and under the condition of nitrogen protection, Heat to 150°C until the cesium carbonate is fully dissolved to obtain a cesium oleate solution with a concentration of 0.4M. Before hot injection, it needs to be heated and dissolved before use. The heating temperature is about 100°C.

[0037] Take 7mL of octadecene solution and 0.4mmol (250mg) of SnI4, put them in a three-necked flask, and vacuumize the mixture at 100°C to remove water and oxygen for 1h.

[0038] Preparation of organic ligands: Take a mixed solution of 2 mL of oleic acid and 2 mL of oleylamine in another flask and vacuumize at 120° C. to remove water and oxygen for 1 hour to obtain an organic ligand solution. After removing water and oxygen, fill the flask with nitrogen protection, take 2mL of organic lig...

Embodiment 2

[0040] First prepare the cesium precursor solution cesium oleate: take 0.8mmol (1.3g) of cesium carbonate powder, 4mL of oleic acid and 16mL of octadecene, mix them, remove water and oxygen at 120°C for 30min, and under the condition of nitrogen protection, Heat to 150°C until the cesium carbonate is fully dissolved to obtain a cesium oleate solution with a concentration of 0.4M. Before hot injection, it needs to be heated and dissolved before use. The heating temperature is about 100°C.

[0041] Take 7mL octadecene solution and 0.4mmol (250mg) of SnI 4 , placed in a three-necked flask, and the mixture was vacuumed at 100°C to remove water and oxygen for 1h.

[0042] Preparation of organic ligand: 2mL of oleic acid and 2mL of oleylamine mixed solution were vacuumized in another flask at 120°C to remove water and oxygen for 1 hour to obtain an organic ligand solution. After removing water and oxygen, fill the flask with nitrogen protection, take 2mL of organic ligand solution...

Embodiment 3

[0044] First prepare the cesium precursor solution cesium oleate: take 0.8mmol (1.3g) of cesium carbonate powder, 4mL of oleic acid and 16mL of octadecene, mix them, remove water and oxygen at 120°C for 30min, and under the condition of nitrogen protection, Heat to 150°C until the cesium carbonate is fully dissolved to obtain a cesium oleate solution with a concentration of 0.4M. Before hot injection, it needs to be heated and dissolved before use. The heating temperature is about 100°C.

[0045] Take 7mL octadecene solution and 0.4mmol (250mg) of SnI 4 , placed in a three-necked flask, and the mixture was vacuumed at 100°C to remove water and oxygen for 1h.

[0046] Preparation of organic ligands: take 2 mL of oleic acid and 2 mL of oleylamine mixed solution and vacuumize in another flask at 120° C. to remove water and oxygen for 1 hour to obtain an organic ligand solution. After removing water and oxygen, fill the flask with nitrogen protection, take 2mL of organic ligand ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com