Preparation method of pesticide residue level benzene

A technology of pesticide residue grade and adsorption column, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, adsorption purification/separation, etc., can solve the requirements of trace detection, many impurity interference peaks, and the price of imported products Advanced problems, to achieve the effect of simple operation and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

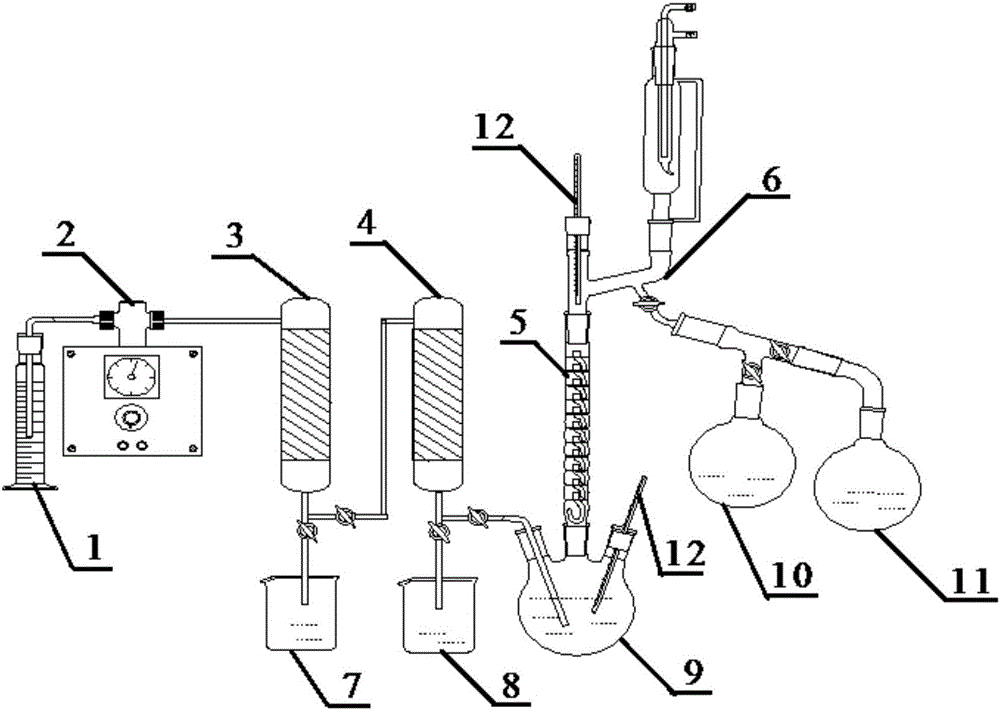

[0030] Step 1. the analytical pure benzene in the reagent bottle 1 is introduced in the adsorption column 3 that desulfurizer is housed by liquid metering pump 2, abandons the benzene of the former volume fraction 10% that flows out from adsorption column 3, then will from adsorption The remaining benzene flowing out in the column 3 is introduced in the drying column 4 that anhydrous calcium chloride is housed and dried;

[0031] Wherein, the carrier of the desulfurizing agent is activated alumina with a particle size of 1.5mm, and the active component is a mixture of copper, palladium, indium and lanthanum; The mass fractions are copper 10%, palladium 0.05%, indium 0.01% and lanthanum 0.05%;

[0032] Step 2. discards the benzene of the previous volume fraction 5% that flows out from drying column 4, then introduces in the there-necked flask 9 the remaining benzene that flows out from drying column 4;

[0033] Step 3. Heat the benzene in the three-necked flask 9 to 75°C to 81...

Embodiment 2

[0038] Step 1. the analytical pure benzene in reagent bottle 1 is introduced in the adsorption column 3 that desulfurizer is housed by liquid metering pump 2, abandons the benzene of the former volume fraction 15% that flows out from adsorption column 3, then will from adsorption The remaining benzene flowing out in the column 3 is introduced in the drying column 4 equipped with 4A molecular sieves and dried;

[0039] Wherein, the carrier of the desulfurizer is a zeolite molecular sieve with a particle size of 2.5mm, and the active components are copper, palladium, tin and lanthanum; the total mass of the desulfurizer is 100%, and the mass of each active component in the desulfurizer is The fraction is copper 15%, palladium 0.05%, tin 0.05% and lanthanum 0.02%;

[0040] Step 2. discards the benzene of the former volume fraction 10% that flows out from drying column 4, then introduces in the there-necked flask 9 the remaining benzene that flows out from drying column 4;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap