Polylactic acid/chemically modified natural rubber blend material and preparing method thereof

A chemically modified, natural rubber technology, applied in the field of polylactic acid/chemically modified natural rubber blend materials and their preparation, can solve problems such as poor toughness and poor ductility, and achieve excellent elongation at break and excellent impact resistance. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

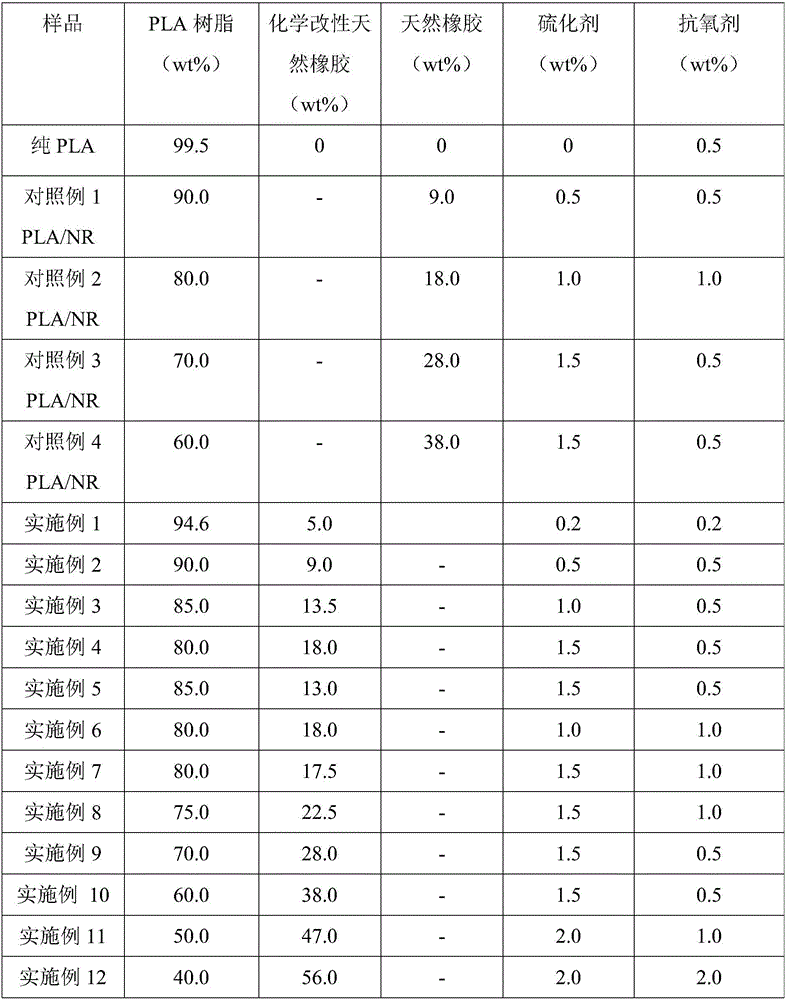

Embodiment 1

[0022] Put 94.0wt% polylactic acid, 5.0wt% glycidyl methacrylate chemically modified natural rubber (polyglycidyl methacrylate graft content is 2.0wt%), 0.2wt% antioxidant 1010 in Mix in a high-speed mixer, add to a Hakke internal mixer, melt and blend at 140-160°C, rotate at a speed of 40rpm, and mix for 10 minutes, then add 0.2wt% vulcanizing agent dicumyl peroxide, rotate at a speed of 30rpm, and continue mixing Take it out after 10 minutes, prepare a standard sample of polylactic acid / chemically modified natural rubber blend material by molding at 160-180° C., and measure the mechanical properties of the sample. The tensile strength was 50.7 MPa, the elongation at break was 52%, the notched impact strength was 15.6 MPa, and the unnotched impact strength was 34.4 MPa.

Embodiment 2

[0024] Put 90.0wt% polylactic acid, 9.0wt% glycidyl methacrylate chemically modified natural rubber (polyglycidyl methacrylate graft content is 2.5wt%), 0.5wt% antioxidant 1010 in Mix in a high-speed mixer, add to a Hakke internal mixer, melt and blend at 140-160°C, speed 40rpm, mixing time 10min, then add 0.5wt% vulcanizing agent dicumyl peroxide, speed 30rpm, continue mixing Take it out after 10 minutes, prepare a standard sample of polylactic acid / chemically modified natural rubber blend material by molding at 160-180° C., and measure the mechanical properties of the sample. The tensile strength was 47.5MPa, the elongation at break was 116%, the notched impact strength was 30.7MPa, and the unnotched impact strength was 112.8MPa.

Embodiment 3

[0026] Put 85.0wt% polylactic acid, 13.5wt% glycidyl methacrylate chemically modified natural rubber (polyglycidyl methacrylate graft content is 4.5wt%), 0.5wt% antioxidant 1010 in Mix in a high-speed mixer, add to a Hakke internal mixer, melt and blend at 130-160°C, rotate at 100rpm, mix for 10min, then add 1.0wt% vulcanizing agent dicumyl peroxide, rotate at 45rpm, and continue mixing Take it out after 10 minutes, and prepare a standard sample of polylactic acid / chemically modified natural rubber blend material by molding at 160-180° C., and measure its mechanical and mechanical properties. The tensile strength was 42.6MPa, the elongation at break was 142%, the notched impact strength was 43.4MPa, and the unnotched impact strength was 117.3MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com